Pneumatic quick-opening shutter butterfly valve

A louver butterfly and valve body technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of the louver valve not opening normally, increasing air consumption or oil consumption, and reducing the opening speed, so as to achieve good sealing performance, Turn on fast, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

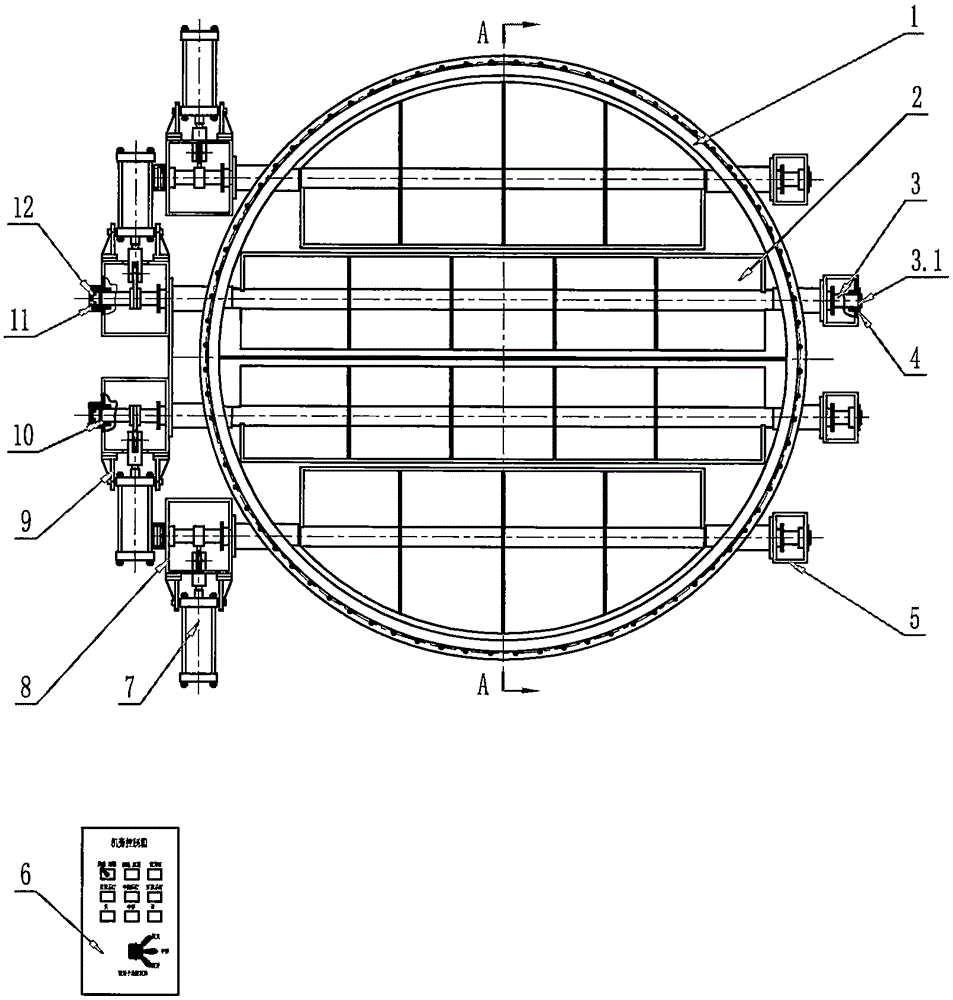

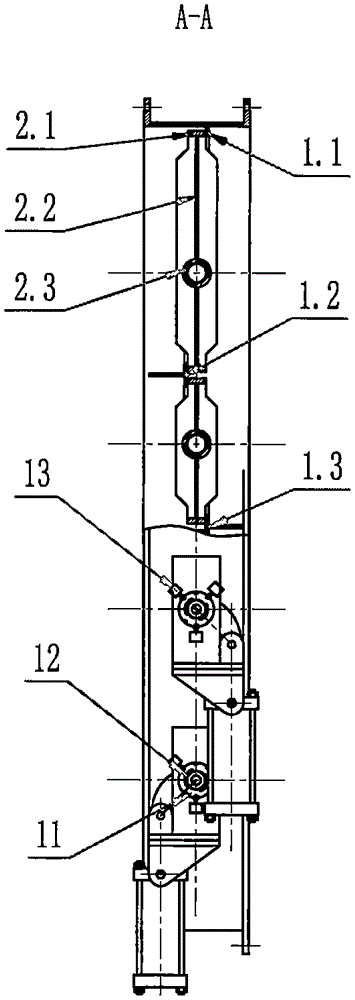

[0014] Such as figure 1 As shown, it includes a valve body 1, a butterfly plate 2, a valve shaft 3 and a driving device 7. The valve body 1 is provided with multiple groups of butterfly plates 2 installed together with corresponding multiple valve shafts 3; The valve shaft 3 is limited by the positioning card 4 to rotate in the valve body 1 through the bearing 10 in the rear box body 5 installed on the valve body 1 and the bearing 10 in the front box body 8; the plurality of valve shafts 3 are respectively Cranks 13 are provided; each of the cranks 13 operates the driving device 7 through the machine side control box 6, respectively drives the corresponding butterfly plate 2 to complete the corresponding opening or closing action in the valve body 1; the driving device 7 is installed on the front box body 8 through a bracket 9, and the driving device 7 can be a pneumatic device or a hydraulic device.

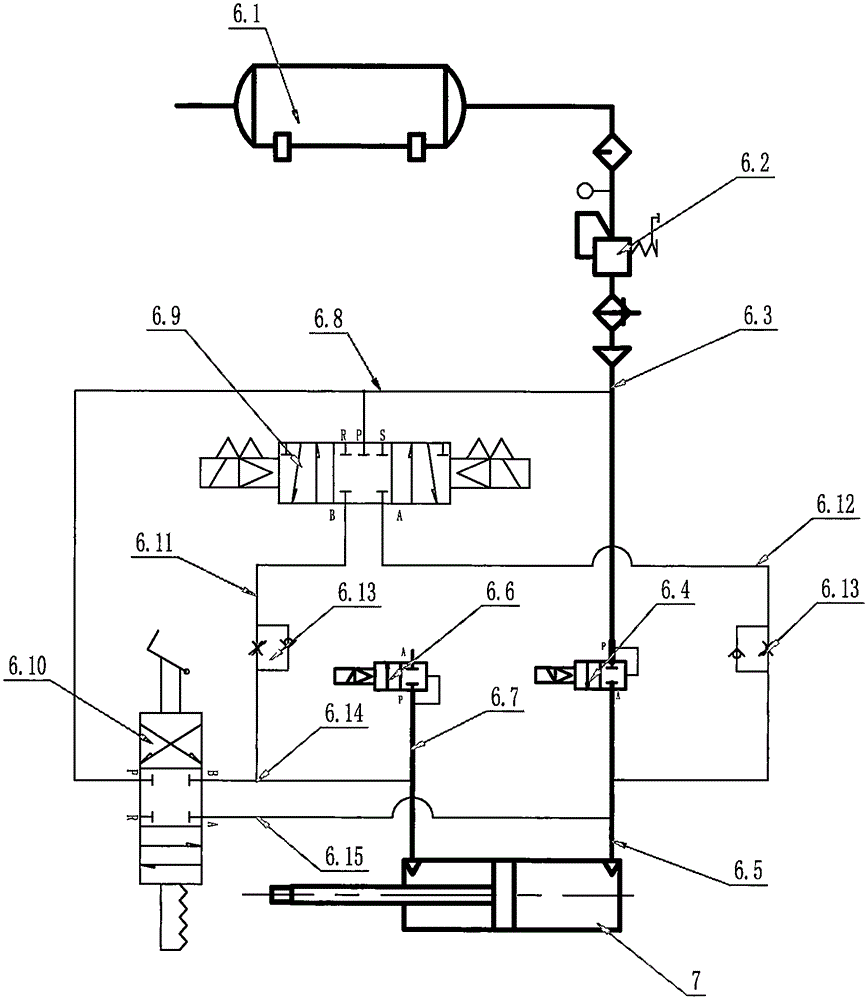

[0015] Such as figure 2 , 3 As shown, the control box 6 beside the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com