Series cycloidal gear reducer

A technology of cycloidal gear and reducer, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission parts, etc., can solve the problems of affecting the quiet environment of the operator, occupying the overall space of the machine, and consuming more metal materials, etc., and achieve saving A large amount of metal, light weight, overcome the effect of easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

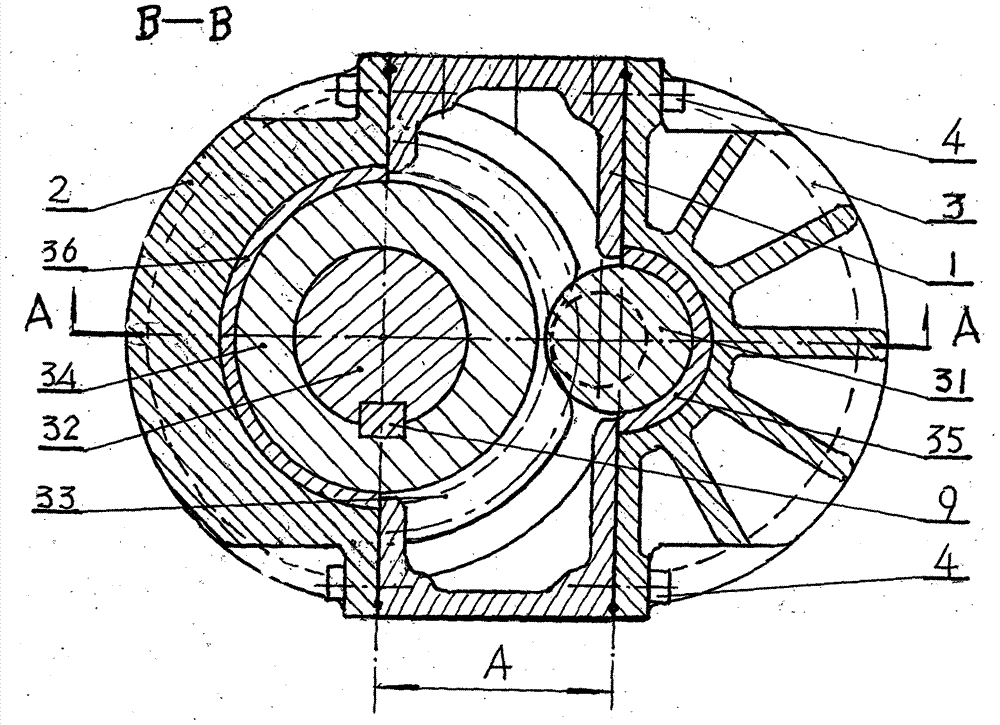

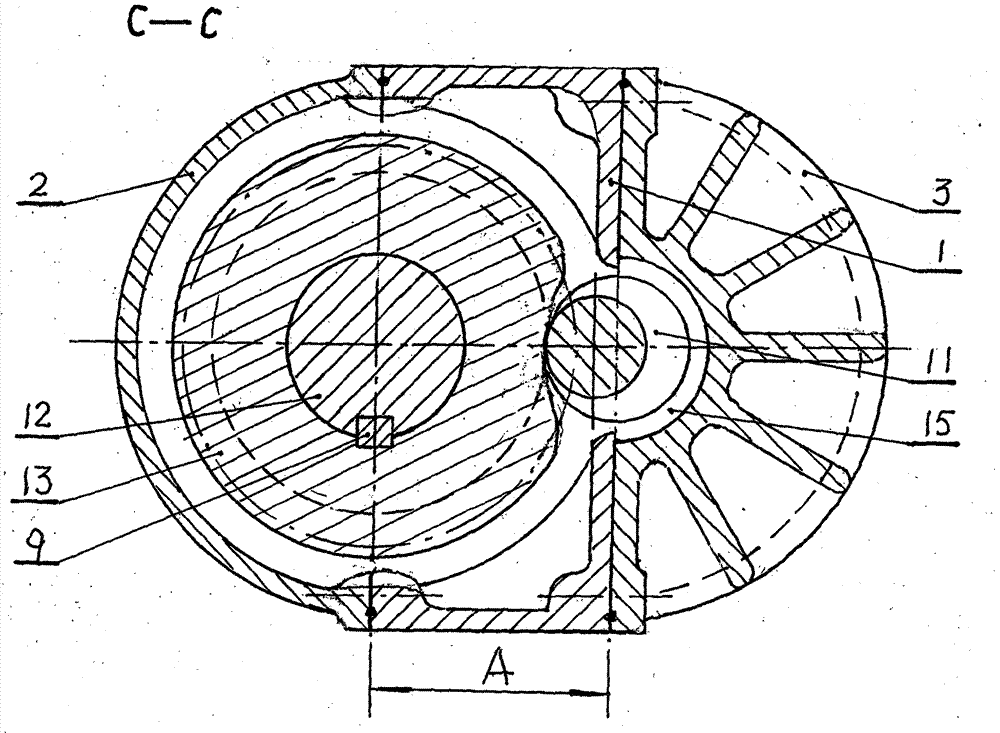

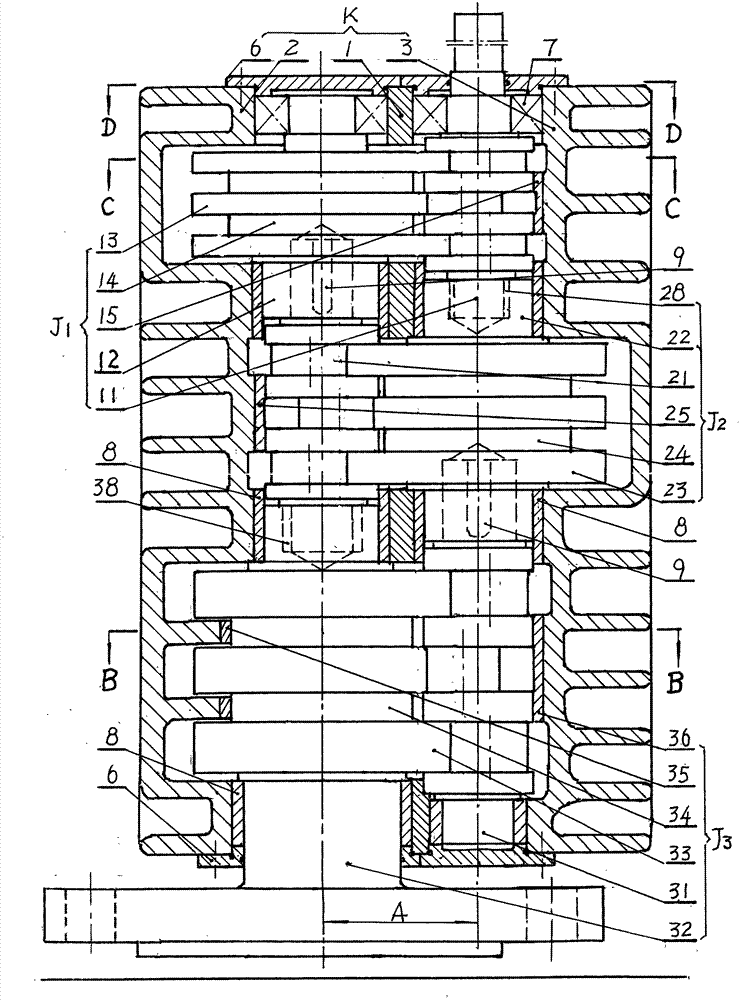

[0027] refer to Figure 1-Figure 5 . In the embodiment described below, a serial cycloidal gear reducer includes a first-stage reduction assembly J1 and a second-stage reduction assembly J2 that are assembled in the same casing K and adopt oppositely rolling cycloidal gear meshing pairs. And the third stage deceleration assembly J3. It is characterized in that the geometric parameters of the cycloidal gear tooth profile curves of the three reduction assemblies J1, J2, and J3 are the same, the radial dimensions of the meshing pairs are the same, the center distance A between the input shaft and the output shaft is equal, and the three reduction assemblies J1, J2, The reduction ratios of J2 and J3 are the same, and the total reduction ratio is the cube of the reduction ratio of the first-stage reduction assembly J1; the axial dimensions of the three reduction assemblies J1, J2, and J3 increase with the increase of the reduction level; the first-stage One end of the first input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com