Rice transplanter type vehicle transmission

A technology for transmissions and vehicles, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of inconvenient operation, difficult disassembly and assembly, larger size of transmission gears, etc., to achieve good manufacturability and The effect of maintaining performance, improving work reliability, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

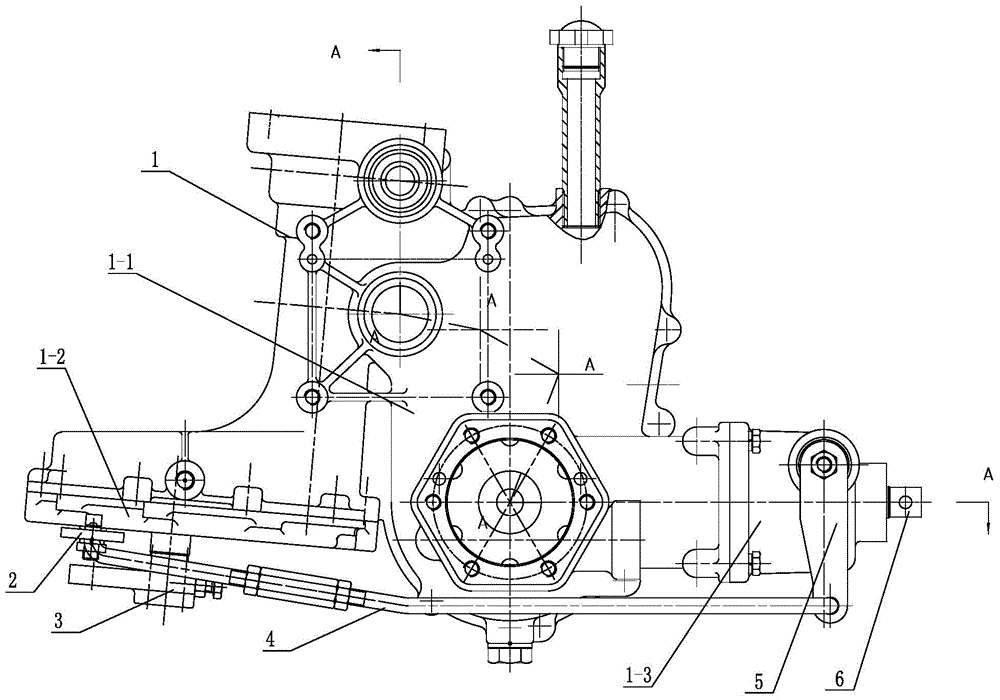

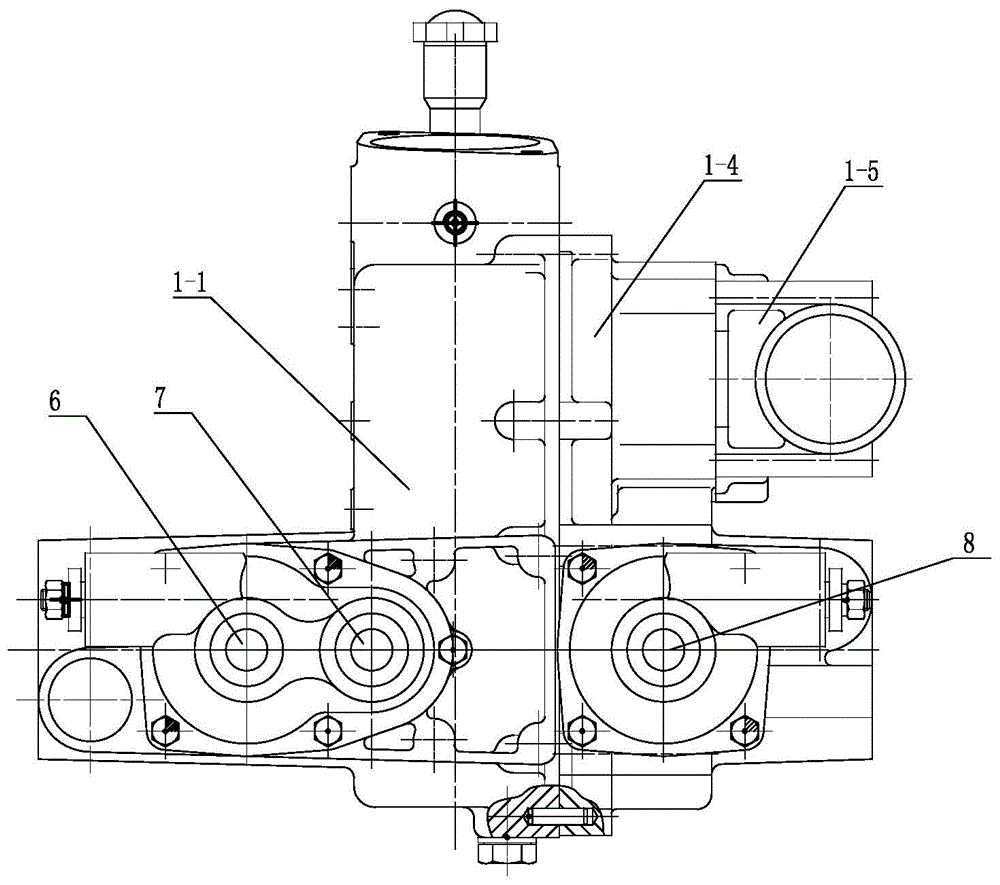

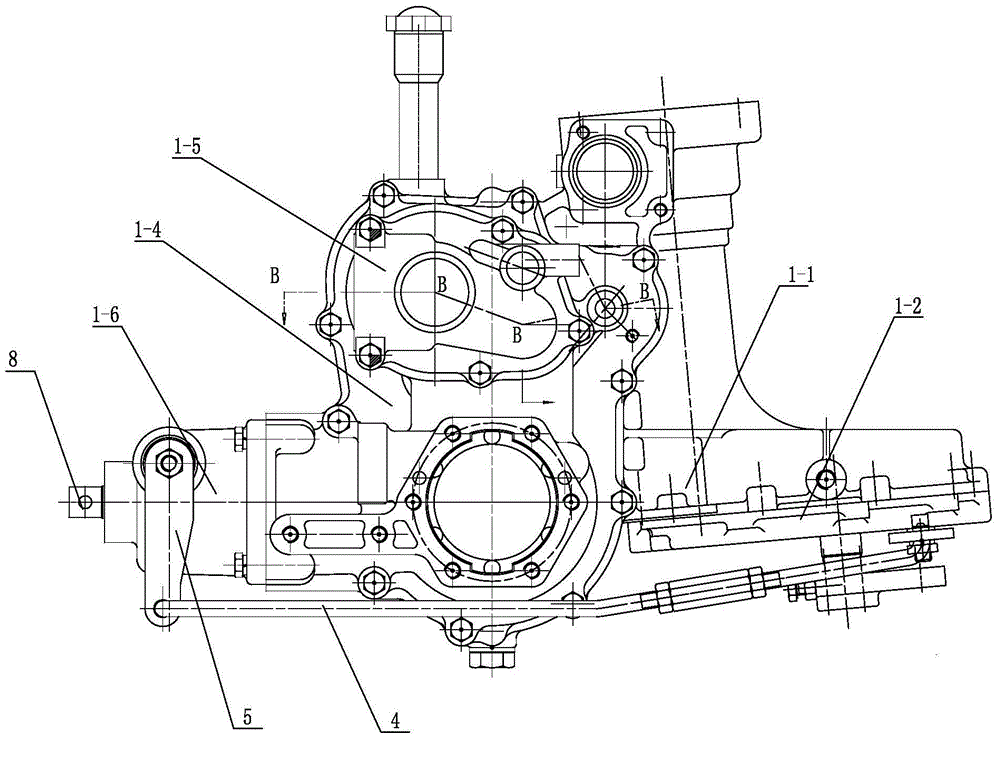

[0029] See Figure 1-7 As shown, the rice transplanting type vehicle transmission of the present invention comprises a transmission case 1, an input shaft 10, a power transmission shaft 13, a central transmission shaft 15, a left half shaft 19, a right half shaft 27, a differential 16, a steering clutch 21 and Brake 26 and steering gear 33.

[0030] See Figure 1~4 As shown, the transmission case 1 of the present invention includes a left casing 1-1 with one side open and having a speed change cavity and a left differential cavity, and a right differential cavity connected to the left casing 1-1. The right housing 1-4, the left housing 1-1 and the right housing 1-4 side are respectively connected with the left steering clutch housing 1-3 and the right steering clutch housing 1-6, the left housing 1-1 and the right The housing 1-4 has an asymmetric structure, and the upper part of the right housing 1-4 has a transfer cavity that is not connected to the cavity of the right dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com