Leakproof organic working medium turbine generator set

A generator set and anti-leakage technology, which is applied in the direction of machines/engines, electromechanical devices, electric components, etc., can solve the problems of working medium leakage, limited life, high cost, etc., and achieve the effect of reliable sealing and anti-leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

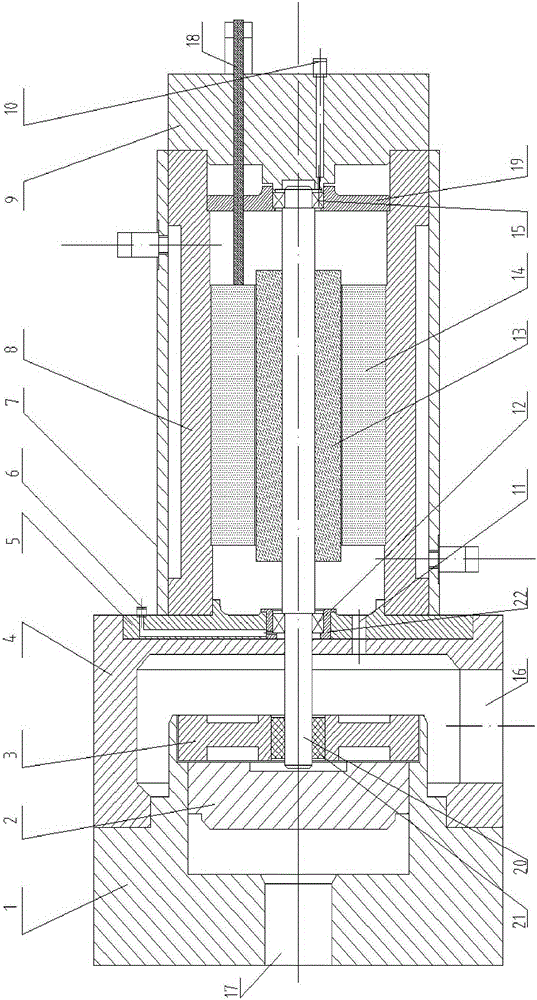

[0020] Such as figure 1 As shown, the present invention provides a kind of anti-leakage turbogenerator set that adopts organic working medium lubrication and cooling bearings, including turbine stationary vanes 2, turbine moving vanes 3, generator rotor 13, generator stator 14 placed in interconnected Inside the turbine casing 4 and the motor casing 8; the turbine moving blade 3 and the generator rotor 13 share the same rotating shaft 20, the bearings are placed at both ends of the generator rotor, and the turbine moving blade is installed in a cantilever type.

[0021] The above-mentioned turbogenerator set includes: turbine stationary blades 2, turbine moving blades 3, generator stator 14, generator rotor 13, rotating shaft 20, shaft coupling 21, and housing assembly.

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com