Pressure-resistant well lid for repair and method for mounting pressure-resistant well lid

A technology of manhole cover and cover body, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of invisible well circles, road collapse around the well cover, and small stress area of well circles. Damage, good drainage effect, improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

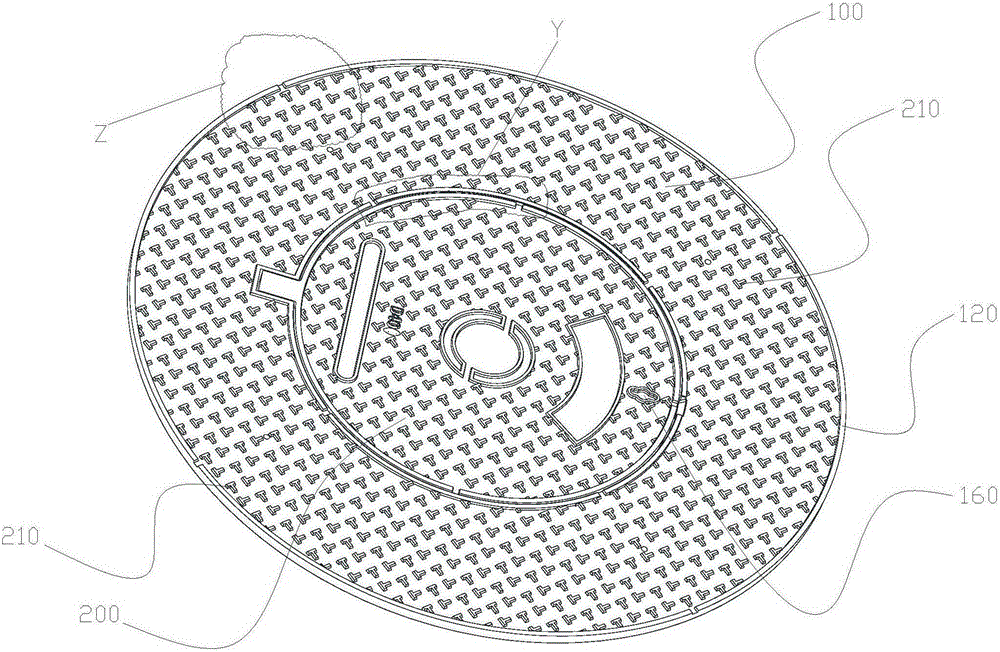

[0049] like Figure 1-Figure 11 As shown, a pressure-resistant manhole cover for repairing comprises a ring body 100 with an annular thin plate shape in cross section and a cover body 200 covering the through hole of the ring body, and the width of the ring body 100 is at least 16cm;

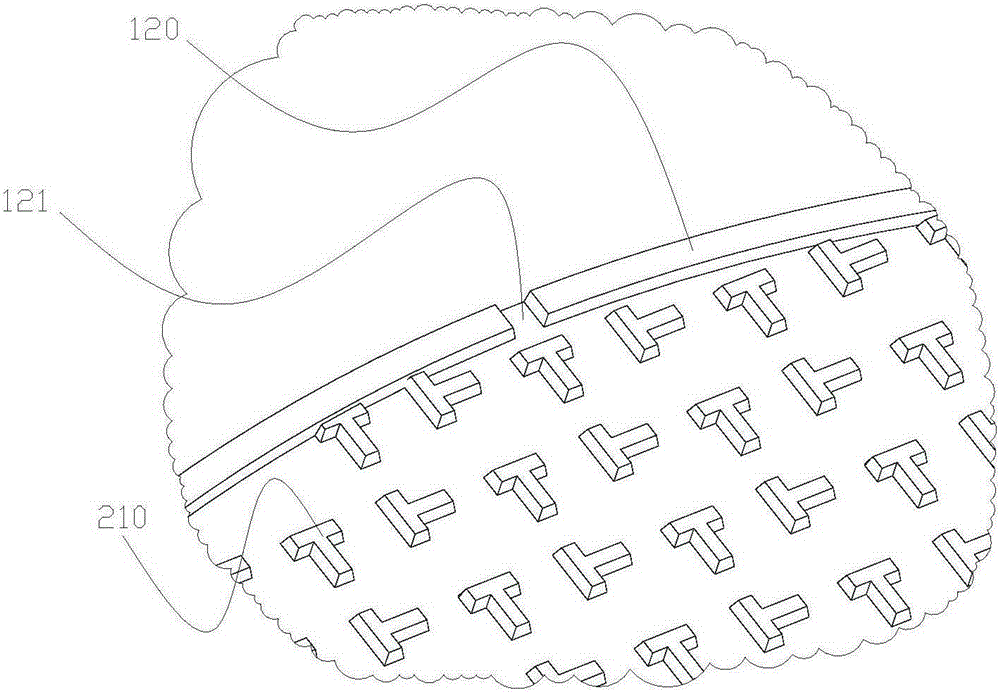

[0050] The outer wall of the ring body and the inner wall of the ring body are respectively provided with a first wrapping 120 and a second wrapping 130, the upper surface of the first wrapping 120 and the lower surface of the first wrapping 120 Respectively beyond the upper surface of the ring body and the lower surface of the second wrapping 130, the upper surface of the second wrapping 130 and the lower surface of the second wrapping 130 respectively exceed the upper surface of the ring body surface and the lower surface of the ring body, the peripheral side of the cover is provided with a third wrapping 220, and the upper surface of the third wrapping 220 and the lower surface of the third w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com