A kind of anti-flash rust styrene-acrylic emulsion and preparation method thereof

A styrene-acrylic emulsion and anti-flash rust technology, which is applied in the field of anti-flash rust styrene-acrylic emulsion and its preparation, can solve the problem of decreased adhesion between the paint film and the metal surface, stains that cannot be completely infiltrated by the paint film, and affect the overall paint film Appearance and other problems, to achieve the effect of solving heavy metal residues, strong mechanical properties, and preventing electrode reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

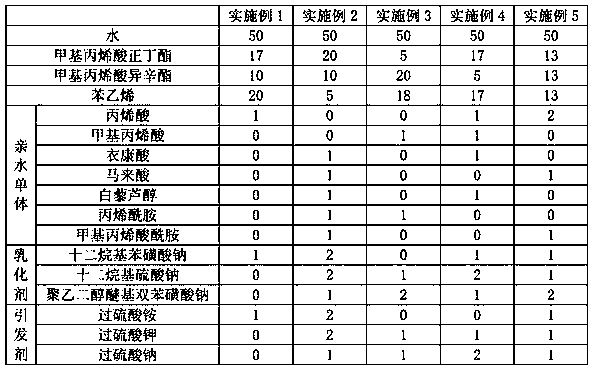

Examples

preparation example Construction

[0026] The preparation method of the anti-flash rust styrene-acrylic emulsion of the present invention may further comprise the steps:

[0027] a. Bottom liquid preparation: Add 30-50% of the total amount of water and 1-3% of the total amount of emulsifier to the reactor with a stirrer, condenser, and constant-flow pump feeding device, and heat up until the temperature in the kettle reaches 75-85°C;

[0028] b. Preparation of monomer solution: styrene, n-butyl methacrylate, isooctyl methacrylate, hydrophilic monomer, total amount of emulsifier 2-4%, total amount of water 30- 50% mixed into a uniform solution, and stirred for 10-30 minutes for later use;

[0029] c. Preparation of initiator solution: add 1-5% of the total amount of initiator to 10% of the total amount of water, and stir to dissolve;

[0030] d. Preparation of post-addition initiator solution: add the remaining initiator to 10% of the total amount of water, stir to dissolve;

[0031] e. When the temperature i...

Embodiment 1

[0036] The anti-flash rust styrene-acrylic emulsion of the present invention mainly includes water, n-butyl methacrylate, isooctyl methacrylate, styrene, acrylic acid, sodium dodecylbenzenesulfonate, ammonium sulfate, and the content of the above components is as follows: The mass percentages are: water 50%; n-butyl methacrylate 17%; isooctyl methacrylate 10%; styrene 20%; acrylic acid 1%; sodium dodecylbenzenesulfonate 1%; ammonium sulfate 1%.

[0037] The preparation method of the anti-flash rust styrene-acrylic emulsion of the present invention may further comprise the steps:

[0038]a. Bottom liquid preparation: Add 30% of the total amount of water and 1% of the total amount of emulsifier to the reactor equipped with a stirrer, condenser, and constant-flow pump feeding device, and raise the temperature until the temperature in the kettle reaches 75°C;

[0039] b. Preparation of monomer solution: under normal temperature and pressure, styrene, n-butyl methacrylate, isoocty...

Embodiment 2

[0046] The anti-flash rust styrene-acrylic emulsion of the present invention mainly comprises water, n-butyl methacrylate, isooctyl methacrylate, styrene, itaconic acid, maleic acid, resveratrol, acrylamide, methacrylic acid Amide, sodium dodecylbenzenesulfonate, sodium laurylsulfate, sodium polyglycol ether bisbenzenesulfonate, ammonium sulfate, potassium persulfate and sodium persulfate, the contents of the above components are calculated by mass percentage For: water 50%; n-butyl methacrylate 20%; isooctyl methacrylate 10%; styrene 5%; itaconic acid 1%; maleic acid 1%; resveratrol 1%; acrylamide 1%; Methacrylic acid amide 1%; Sodium dodecylbenzene sulfonate 2%; Sodium lauryl sulfate 2%; Potassium sulfate 2%; Sodium persulfate 1%.

[0047] The preparation method of the anti-flash rust styrene-acrylic emulsion of the present invention may further comprise the steps:

[0048] a. Bottom liquid preparation: Add 50% of the total amount of water and 3% of the total amount of emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com