A kind of preparation method of starch-based cement hydration heat control material

A technology of cement hydration and heat regulation, which is applied in the field of building material concrete admixtures, can solve the problems of complex material preparation process, unsatisfactory regulation effect, and long reaction time, so as to shorten the reaction time, reduce the heat release rate, and reduce the environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

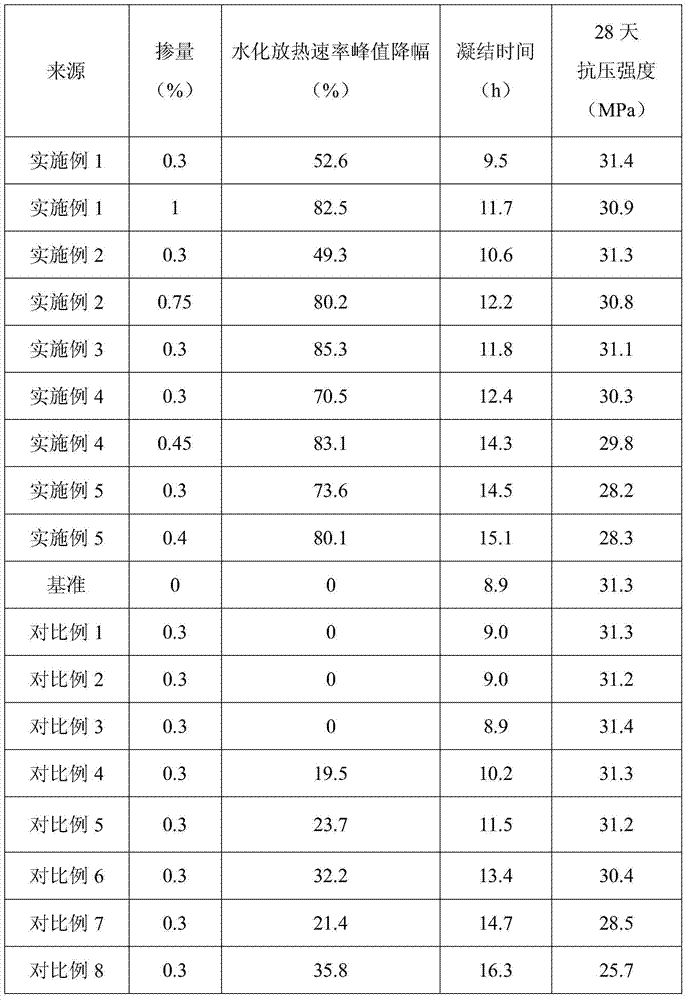

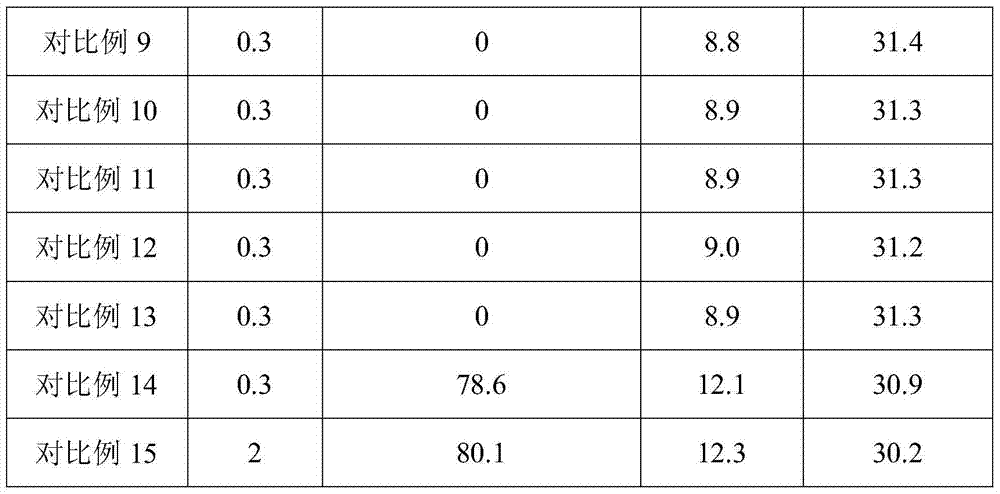

[0027] Mix 700g of commercially available dextrin with a DE value of 4 and a solubility in cold water of 65%, 70g of wheat starch, 200g of succinic anhydride and 150g of phthalic anhydride in a high-speed mixer, and add it to a twin-screw extruder to melt and extrude . The processing temperature of the twin-screw extruder is 90°C, 110°C, 120°C, 125°C from the feed port to the discharge port, the screw speed is 120r / min, and the residence time of the material in the barrel is 10min. The extruded product is pulverized and passed through a 100-mesh sieve to obtain the starch-based cement hydration heat regulating material of the present invention.

Embodiment 2

[0029] 800g DE value is 6, cold water solubility is 72% commercially available dextrin, 160g cornstarch, 180g glutaric anhydride and 60g succinic anhydride are mixed uniformly in the high-speed stirring mixer, add twin-screw extruder and melt and extrude. The processing temperature of the twin-screw extruder is 70°C, 85°C, 90°C, 100°C from the feed port to the discharge port, the screw speed is 150r / min, and the residence time of the material in the barrel is 8min. The extruded product is pulverized and passed through a 100-mesh sieve to obtain the starch-based cement hydration heat regulating material of the present invention.

Embodiment 3

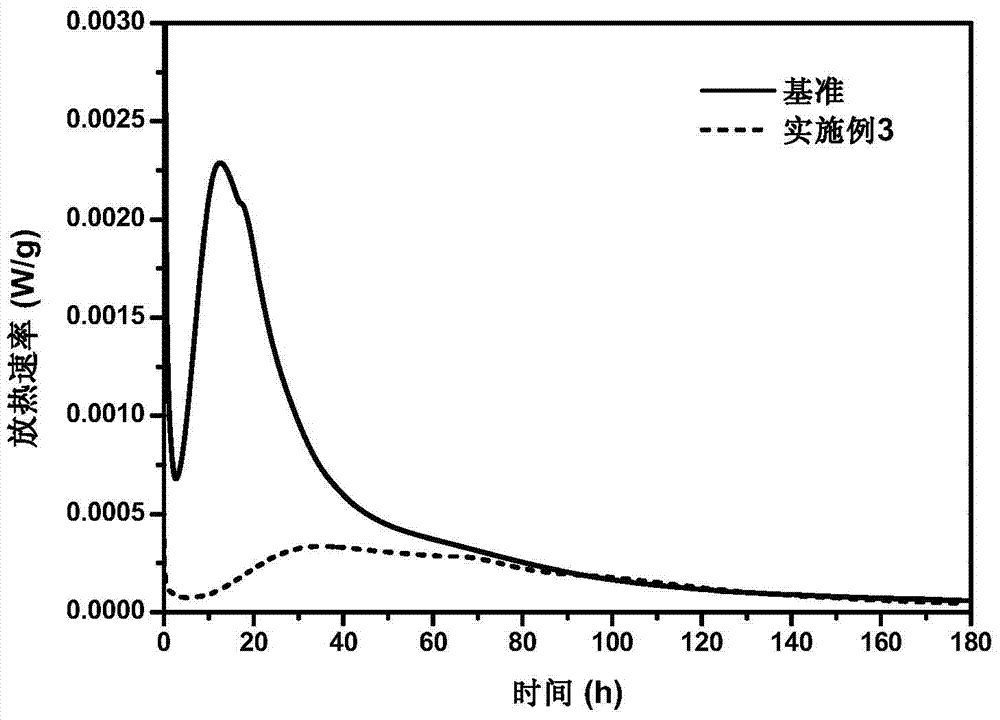

[0031] Mix 600g of commercially available dextrin with a DE value of 9 and a solubility in cold water of 78%, 90g of waxy cornstarch, 220g of succinic anhydride and 320g of phthalic anhydride in a high-speed stirring mixer, and add to a twin-screw extruder to melt extrude. The processing temperature of the twin-screw extruder is 90°C, 120°C, 130°C, 140°C from the feed port to the discharge port, the screw speed is 80r / min, and the residence time of the material in the barrel is 15min. The extruded product is pulverized and passed through a 100-mesh sieve to obtain the starch-based cement hydration heat regulating material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com