Strengthening treatment method for glass parts

A strengthening treatment and component technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low compressive stress, achieve high compressive stress, and maintain the effect of strengthening layer depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

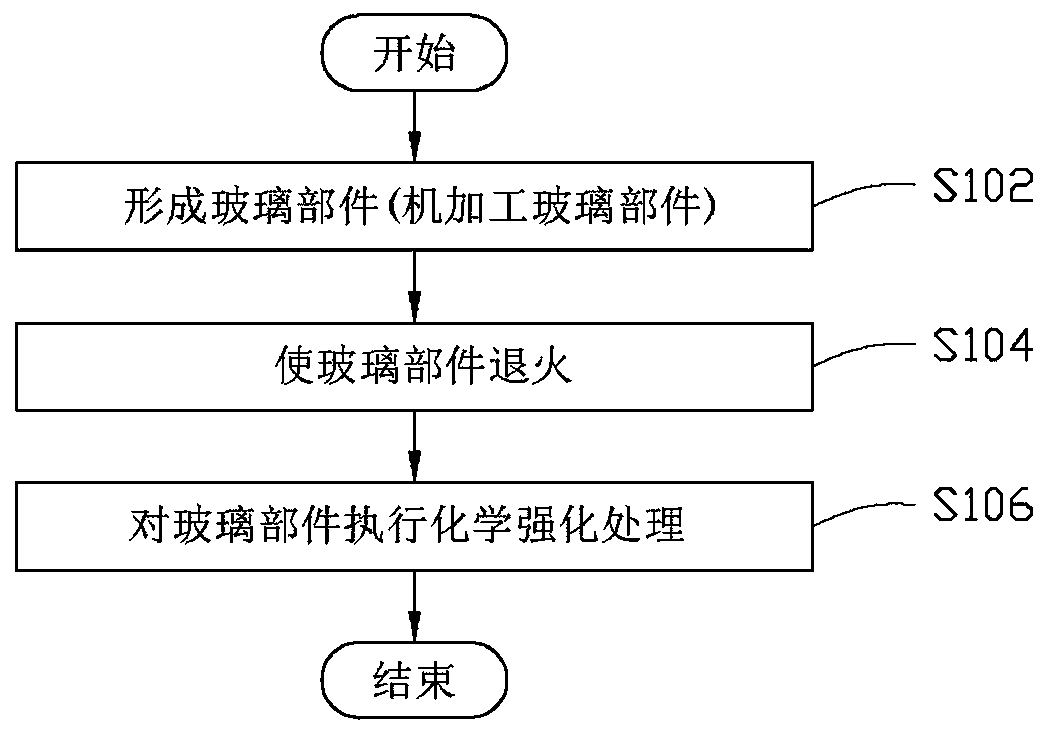

[0013] see figure 1 , is a flow chart of a glass component strengthening treatment method provided in an embodiment of the present invention. Wherein, the glass part strengthening treatment method comprises the following steps:

[0014] Step S102: forming a glass part. Forming the glass part can be achieved by means of thermoforming process, melting process or float process. Among them, the float process generally floats molten glass on the surface of molten metal (eg, tin) and allows the molten glass to cool. Fusion processes typically blend raw materials into glass compositions that are melted and conditioned to create molten glass. Molten glass is fed into the trough until the molten glass flows evenly across the sides of the trough. The glass is then rejoined or melted and drawn down to form a continuous flat sheet of glass that fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com