Engraver applied to plane glass

A technology of flat glass and engraving machine, which is applied in the fields of engraving and decorative arts to achieve the effect of facilitating engraving work, reducing wear and preventing pollution of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

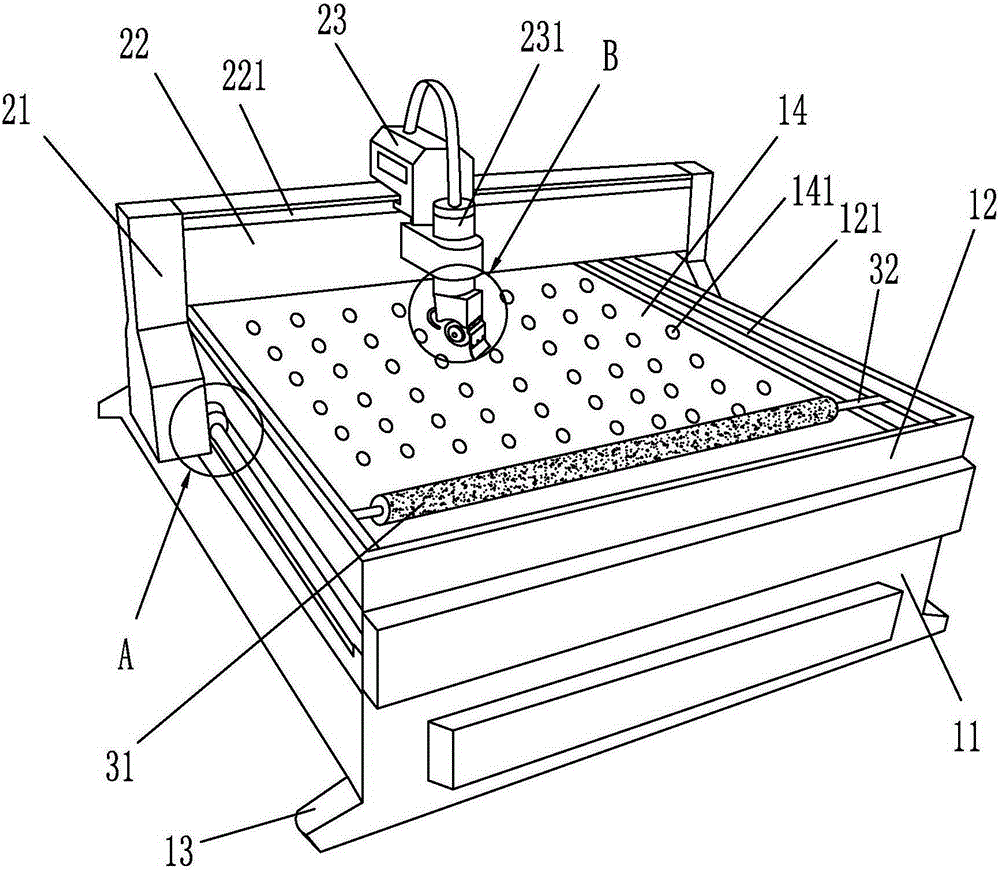

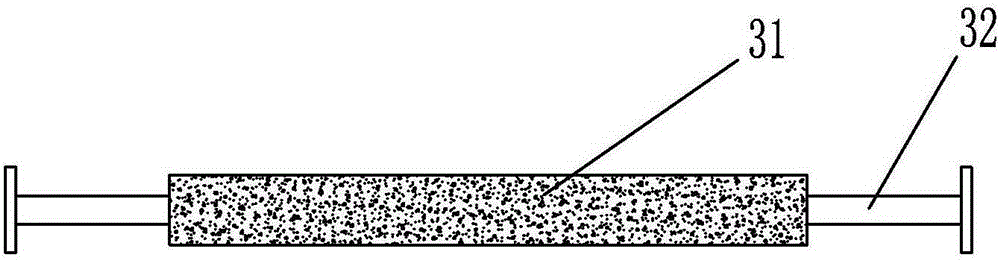

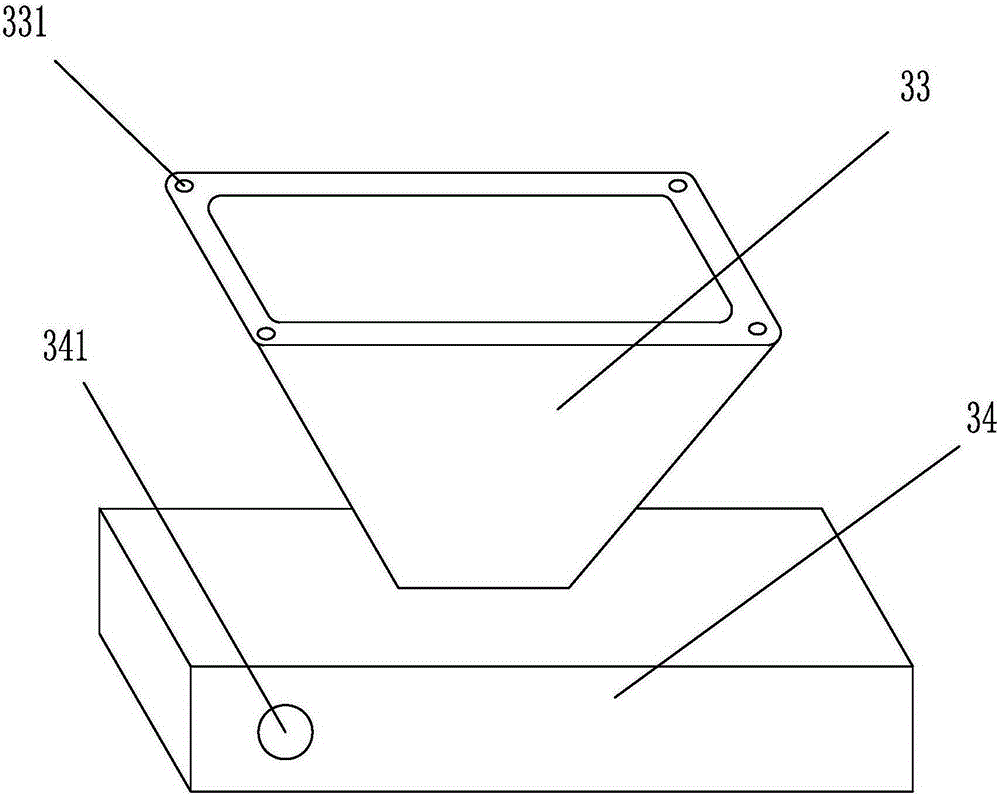

[0027] Such as Figure 1 to Figure 5As shown, an engraving machine applied to flat glass includes an engraving machine body 11, a moving mechanism and a cleaning device. The engraving machine body 11 is provided with a moving mechanism, and the engraving machine body 11 is provided with a cleaning device. The top of the flower machine body 11 is provided with a protective frame 12, and the protective frame 12 is fixed around the engraving machine body 11. The left and right sides of the protective frame 12 are provided with a second moving track 121, and the second moving track 121 is in phase with the rotating shaft 32. Matching, through the setting of the second moving track 121 , the cleaning device is moved in the second moving track 121 to complete the work of cleaning the leaking workbench 14 . The engraving machine body 11 is provided with a leaking workbench 14, and the leaking workbench 14 is evenly provided with leaking holes 141. The lower end of the engraving machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com