Internal expansion type roundness correcting machine for gear rings

A technology of calibration machine and ring gear, which is applied in the direction of using mechanical devices, mechanical measuring devices, mechanical counters/curvature measurement, etc., which can solve the problems of poor calibration quality, low calibration work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

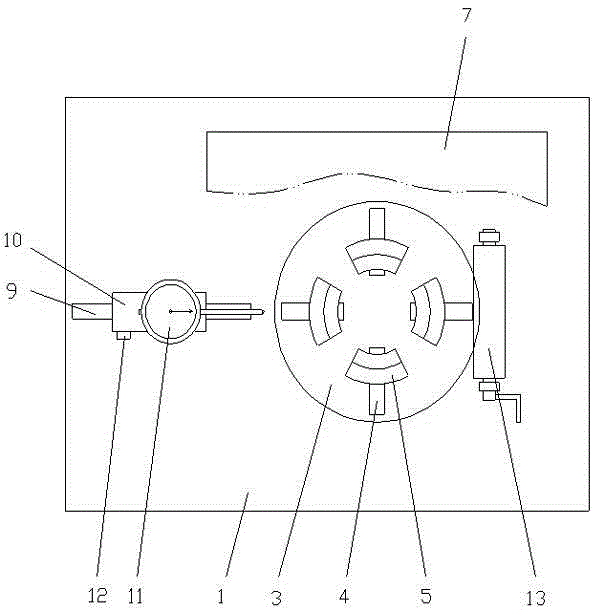

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, the ring gear internal expansion roundness correction machine in this embodiment includes a support 1, a slewing support 2 whose inner ring is fixed on the support, a correction platform 3 fixed on the outer ring of the slewing support, and Four dovetail guide rails 4 evenly arranged on the correction platform (in different embodiments, the number of dovetail guide rails can be three or other numbers above three), the fan ring correction block 5 slidingly matched with the dovetail guide rails, fixed on The L-shaped support plate 6 on the support, the hydraulic jack 7 vertically fixed on the L-shaped support plate, and the pressure head 8 fixed on the lower end of the hydraulic jack piston rod, the radius of the outer circle of the fan ring correction block is the same as The radii of the inner holes of the ring gear are eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com