An operation method of electric vehicle compartment welding assembly line

A technology of welding assembly line and operation method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing the labor intensity of employees, achieve the effects of reducing the labor intensity of employees, solving the difference in working hours, and reducing the intensity of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

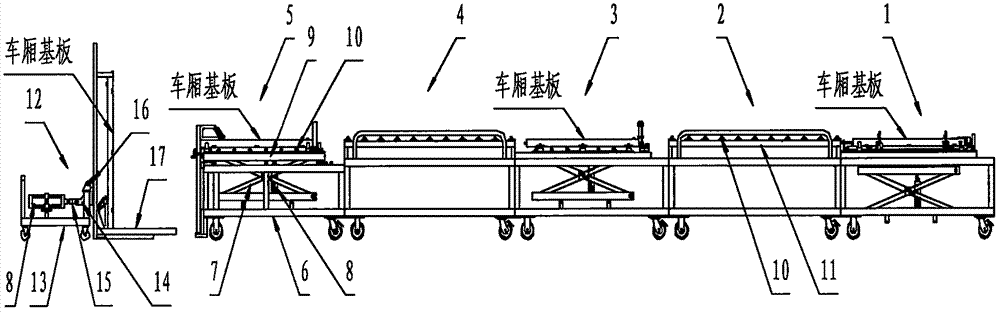

[0017] The first temporary storage frame 2 is set between the first lifting frame 1 and the second lifting frame 3, the second temporary storage frame 4 is set between the second lifting frame 3 and the third lifting frame 5, and the third lifting frame A self-turning frame 12 is arranged at the end of the frame 5; the structures of the first lifting frame 1, the second lifting frame 3 and the third lifting frame 5 are the same, all of which are: a lifting mechanism 7 is set in the mobile frame 6, and the lifting mechanism Support platform 9 is arranged above 7, and cylinder 8 is arranged between the base of lifting mechanism 7 and support platform 9, and at least two rows of horn bearings 10 are evenly distributed along the direction of operation process above support platform 9; The structures of the storage racks 4 are the same, both: a temporary storage platform 11 is set above the mobile frame 6, and at least two rows of horn bearings 10 are evenly distributed above the te...

Embodiment 2

[0019] The first lifting frame 1, the first temporary storage frame 2, the second lifting frame 3, the second temporary storage frame 4, and the third lifting frame 5 are connected in turn to form the whole welding line, and move from the turning frame 12 to the third lifting frame. Behind the lifting frame 5, the carriage substrate is placed above the horn bearing 10 of the support platform 9 of the first lifting frame 1, and the carriage substrate is finely adjusted and slid above the horn bearing 10 to the position to be processed, and each component is welded on the carriage substrate, and the welding After completion, the cylinder 8 in the lifting mechanism 7 of the first lifting frame 1 promotes the support platform 9 to rise, so that the support platform 9 and the temporary storage platform 11 of the first temporary storage frame 2 are located on the same horizontal line, and the carriage substrate is pushed along the horn bearing. 10 slides to the top of the horn bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com