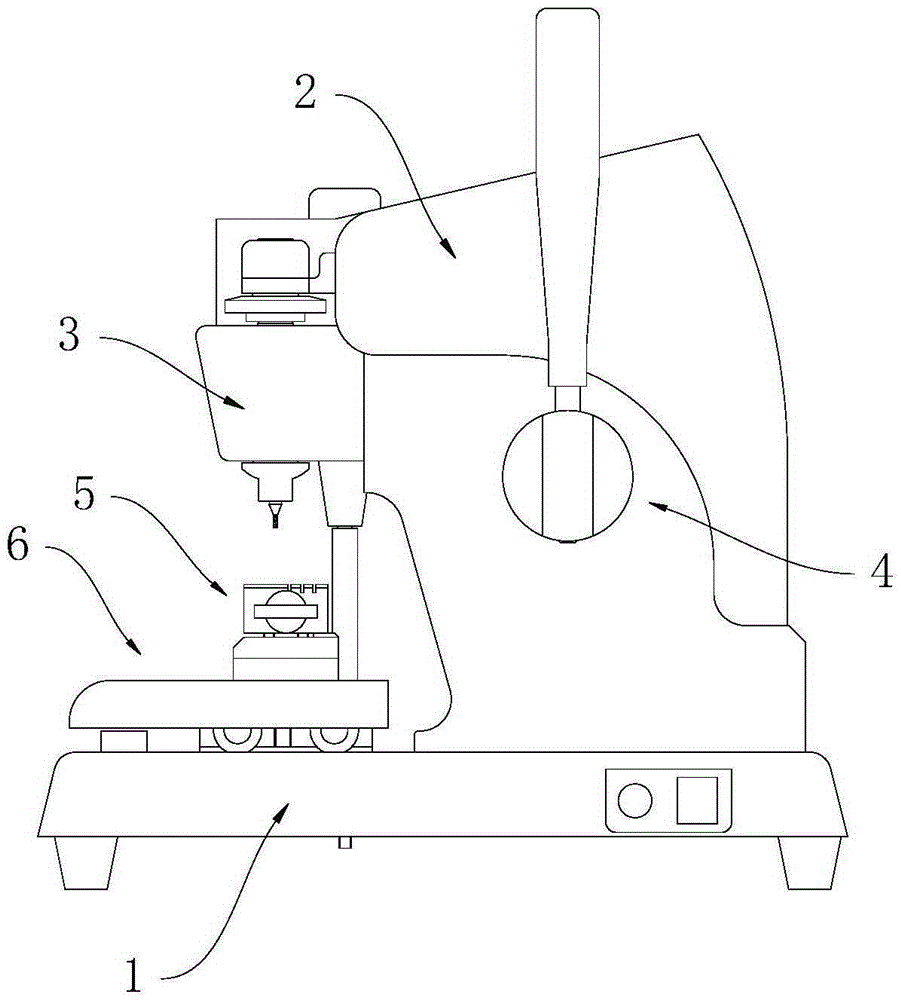

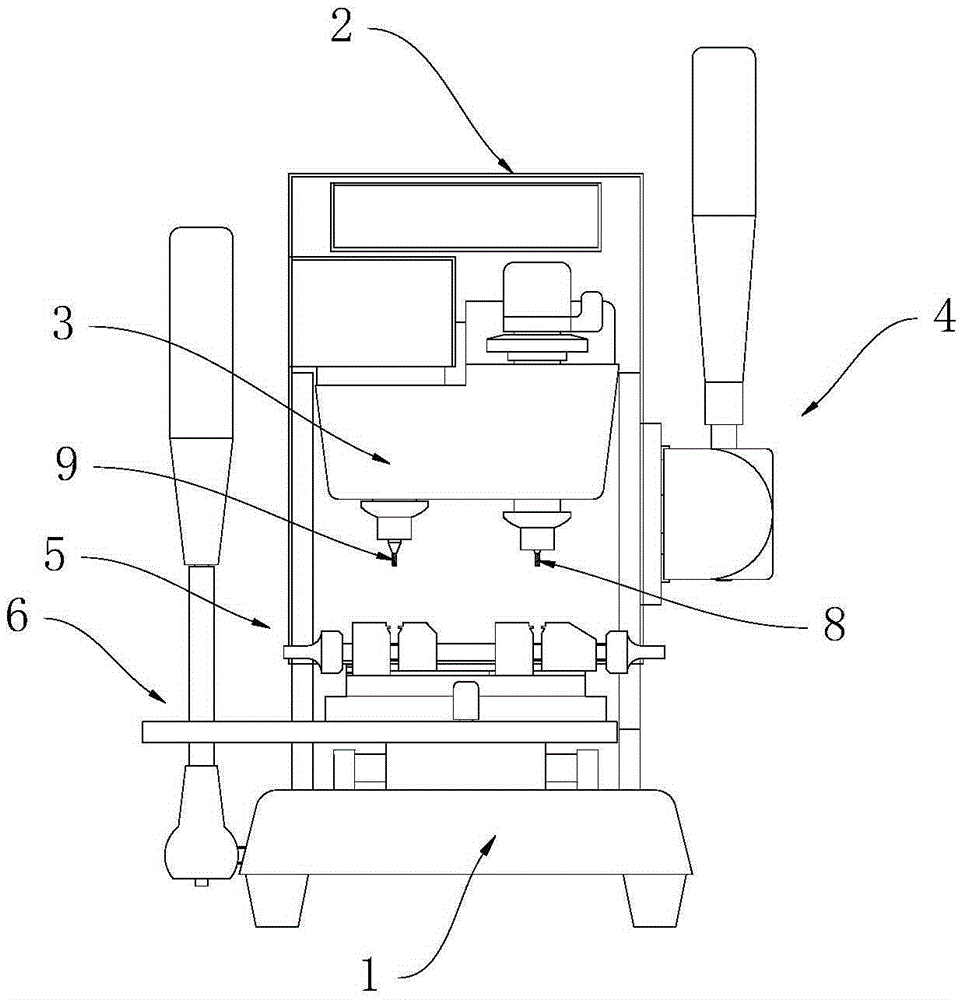

Key machining equipment

A processing equipment and key technology, applied in the field of key processing equipment, can solve problems such as poor adjustability and controllability, inability to adjust left and right, and failure to achieve processing effects, and achieve good adjustability and controllability and good market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

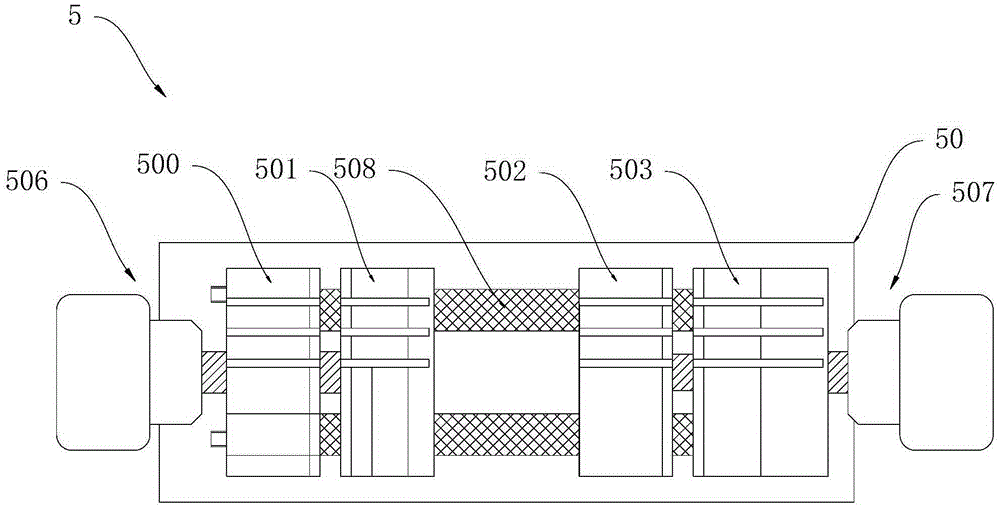

[0041] In this example, combined with Figure 3 to Figure 5 As shown, the clamp assembly 5 includes a clamp support 50, and a first fixed block 500, a first movable block 501, a second fixed block 502 and a second movable block 503 are arranged side by side on the clamp support 50, so that The first fixed block 500 is arranged adjacent to the first movable block 501 and a first jaw 504 for clamping a key is formed between them, and the second fixed block 502 is arranged adjacent to the second movable block 503 And there is formed a second jaw 505 for clamping the key blank between the two, the first fixed block 500 and the second fixed block 502 are fixed on the clamp support 50, and the first fixed block 500 is provided with There is a first locking mechanism 506 for driving the first movable block 501 to reciprocate and slide, and the second fixed block 502 is provided with a second locking mechanism 507 for driving the second movable block 503 to reciprocate and slide. The...

Embodiment 2

[0050] In this example, combined with Figure 6 to Figure 8 As shown, the lifting mechanism 3 is provided with a probe margin adjustment mechanism 30, the probe margin adjustment mechanism 30 includes a sleeve 300, the top of the sleeve 300 is screwed with a plug 301, the The center of the plug 301 is pierced with a telescopic rod 302, the upper end of the plug 301 is provided with an adjustment ring 303, and the adjustment ring 303 is sleeved on the telescopic rod 302, and the edge of the top of the adjustment ring 303 is provided with a relative The first bump 304 and the second bump 305 extend from the bottom of the first bump 304 to the top of the second bump 305 to form a first slope 306, from the bottom of the second bump 305 to the first bump The top of the block 304 is extended to form a second slope 307, and a pin 308 is vertically pierced on the telescopic rod 302, and the two ends of the pin 308 are respectively overlapped on the first slope 306 and the second slope...

Embodiment 3

[0055] In this example, combined with Figure 9 to Figure 11 As shown, the translation mechanism 6 includes two Y-axis sliders 600 fixed on the base 1 in parallel, and the two Y-axis sliders 600 pass through and are slidably connected to a Y-axis slider 601. The Y-axis Two X-axis sliders 602 are fixed in parallel on the slider 601, both of which pass through and are slidably connected to an X-axis slider 603, and a carrier 604 is fixed on the top of the X-axis slider 603 , the stage 604 is used to carry the fixture assembly 5, the side of the base 1 is provided with a rocker 605, the stage 604 is provided with a first universal bearing 606, and the side of the base 1 is provided with The second universal bearing 607, the rocker 605 passes through the first universal bearing 606 and the second universal bearing 607 in turn, and the rocker 605 drives the stage 604 to translate along the X-axis and / or the Y-axis direction .

[0056] In the above translation mechanism, the stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com