Bidirectional grid connected inverter

A technology of inverters and inverter circuits, applied in the field of bidirectional grid-connected inverters, can solve problems such as long development cycle, high error rate, and cumbersome programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention is specifically described below by means of drawings and examples.

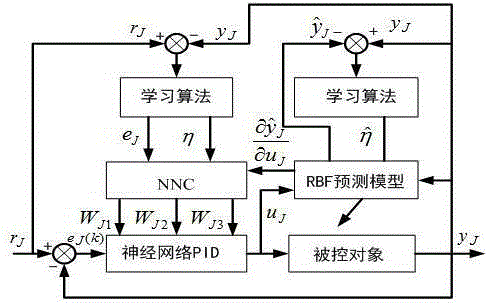

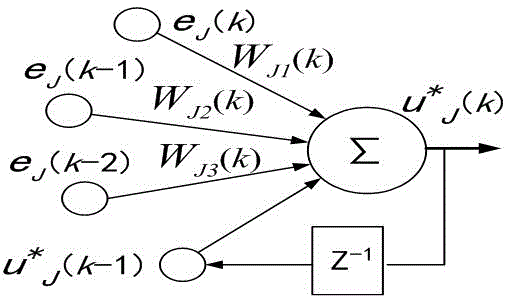

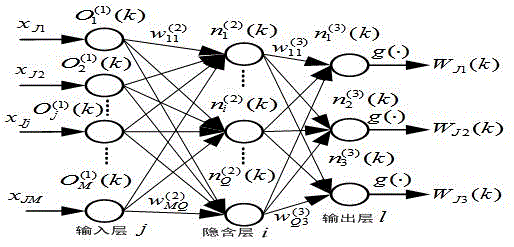

[0090] A bidirectional grid-connected inverter, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown, including power supply U dc , with the supply U dc Parallel capacitor C and three-way inverter circuit, there are three inductance L, capacitor R, and inductor L connected in series between the inverter circuits 1 , resistance R 1 And AC power supply, capacitor R, inductor L 1 A capacitor C is connected in parallel between 1 ; The AC power supply includes U a , U b , U c .

[0091] Different from the grid-connected inverter using inductance filtering, the topology structure using LCL filter adds capacitance and inductance to the AC output side. Assuming that the voltage fluctuations at both ends of the DC bus of the grid-connected inverter are not considered, the voltage of the three-phase grid is symmetrical and stable, and the switching components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com