Special installation rod of U-type seat

A kind of installation rod, U-shaped technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high work intensity and hidden dangers for the safety of operators, so as to achieve continuous stability, service level improvement, good economic benefits and social benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

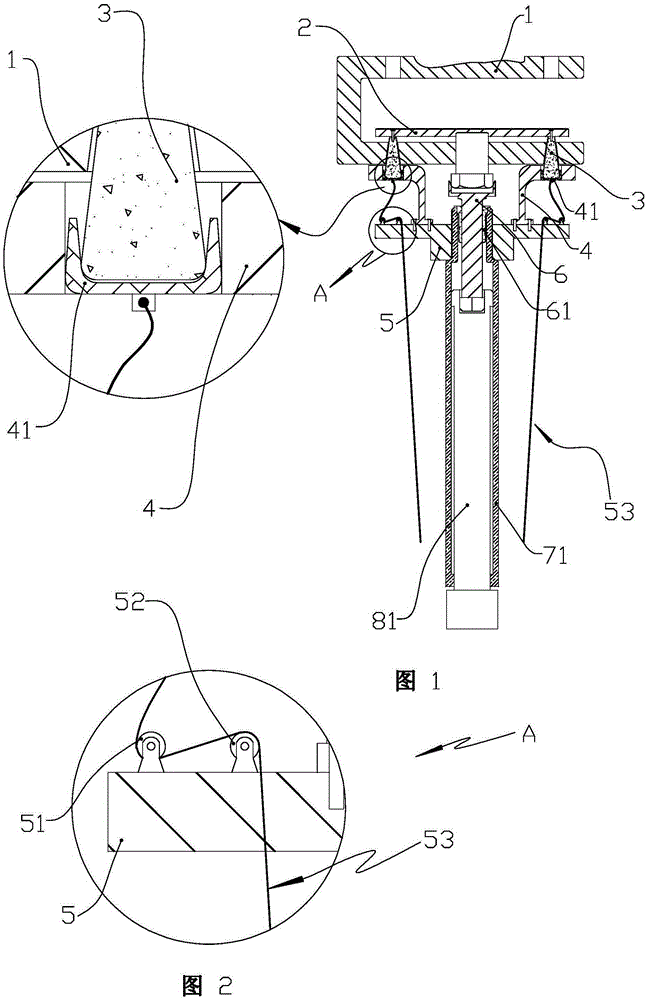

[0027] Such as figure 1 and figure 2 A special mounting rod for a U-shaped seat shown includes two L-shaped support arms 4, a support platform 5, a fastening rod 6, an outer rod 71 and an inner rod 81. The U-shaped seat 1 of the bird repellent it is aimed at includes a pressing plate 2 and a tapered column 3 connected on the pressing plate. Make the tapered column 3 pass through from bottom to top in the tapered hole on the lower arm of the U-shaped seat. Obviously, the axial length of the tapered column will be greater than the axial length of the tapered hole, and the taper of the two is consistent. Furthermore, it needs to be emphasized that the working principle of the tapered column is |: the hardness value of the metal material made of the tapered column is smaller than the hardness value of the material made of the U-shaped seat, so that when the tapered column is subjected to upward push and pull, the cone The column will be squeezed by the tapered hole to produce s...

Embodiment approach 2

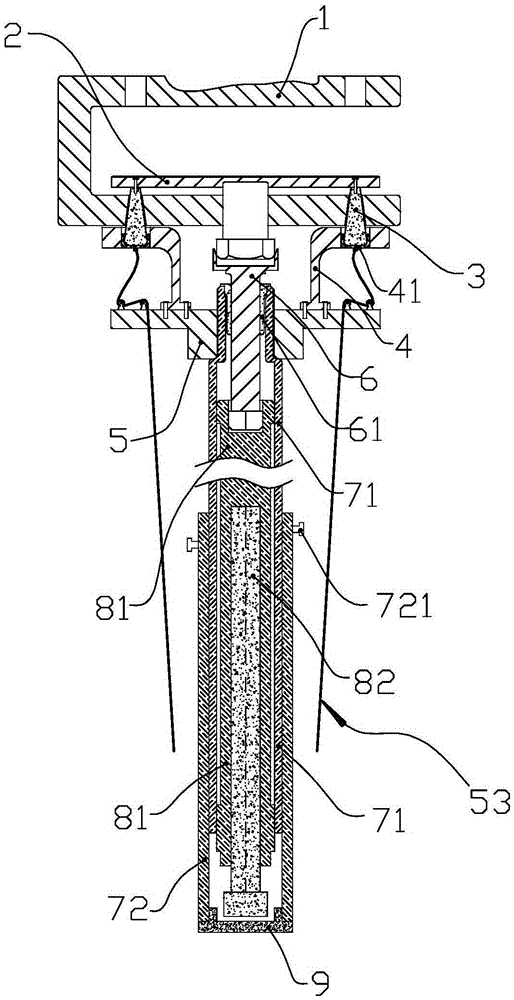

[0040] Such as image 3 As shown, the difference from the above-mentioned embodiments is that in this embodiment, the axial length of the special installation rod can be adjusted. For this reason, it is also provided with two outer rods 72 and two inner rods 82, and the structures of the outer rod one 71 and the inner rod one 81 have been adapted and improved.

[0041] The second inner rod 82 is a hexagonal prism rod, and the second outer rod 72 is a tubular rod with an axially extending cylindrical cavity. The cylindrical cavity diameter of the second outer rod 72 is consistent with that of the first outer rod 71 .

[0042] An axial hexagonal prism hole is set from the lower end surface of the inner rod one 81, so that the inner rod two 82 can move axially in a straight line in the hexagonal prism hole of the inner rod one 81, and rotate the inner rod 82 can drive the inner rod 1 81 to rotate around the axis, so that the outer rod 2 72 can move axially and linearly relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com