A functional test device for the water inlet component of the reactor pressure vessel insulation layer

A pressure vessel and test device technology, which is applied in the field of functional test devices for reactor pressure vessel insulation layer water inlet components, can solve the problems of functional verification of passive reactor pressure vessel insulation layer water inlet components, etc., and achieve stable and reliable simulation. Reasonable structural composition and strong simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

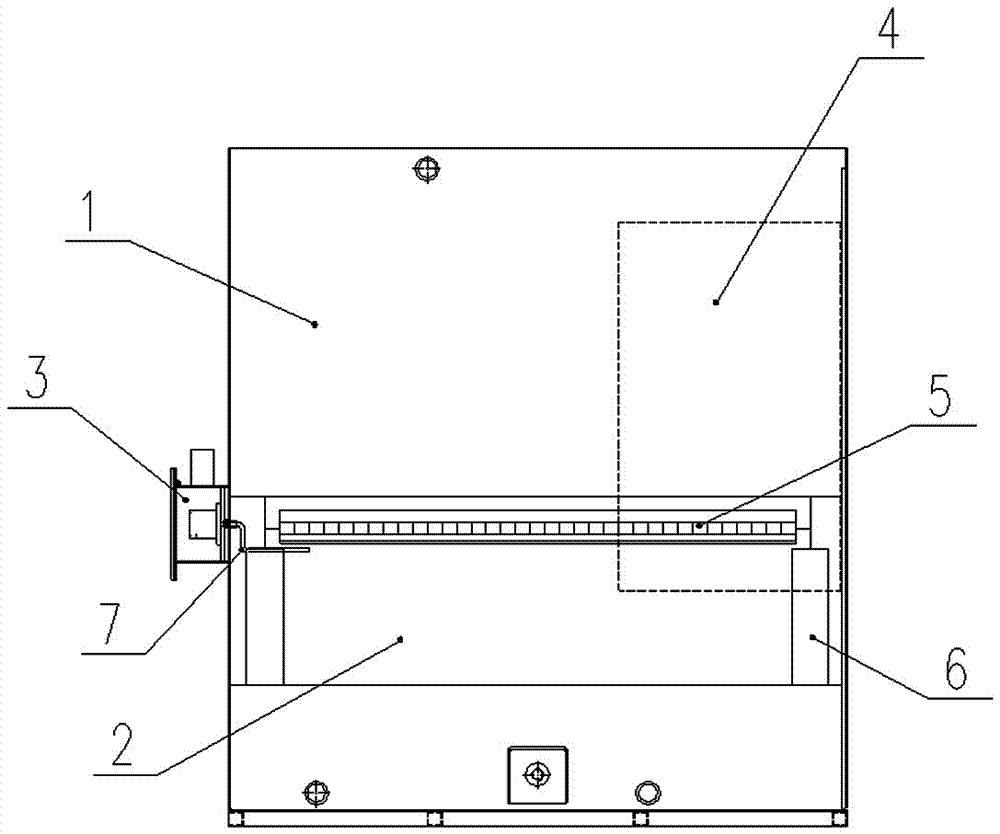

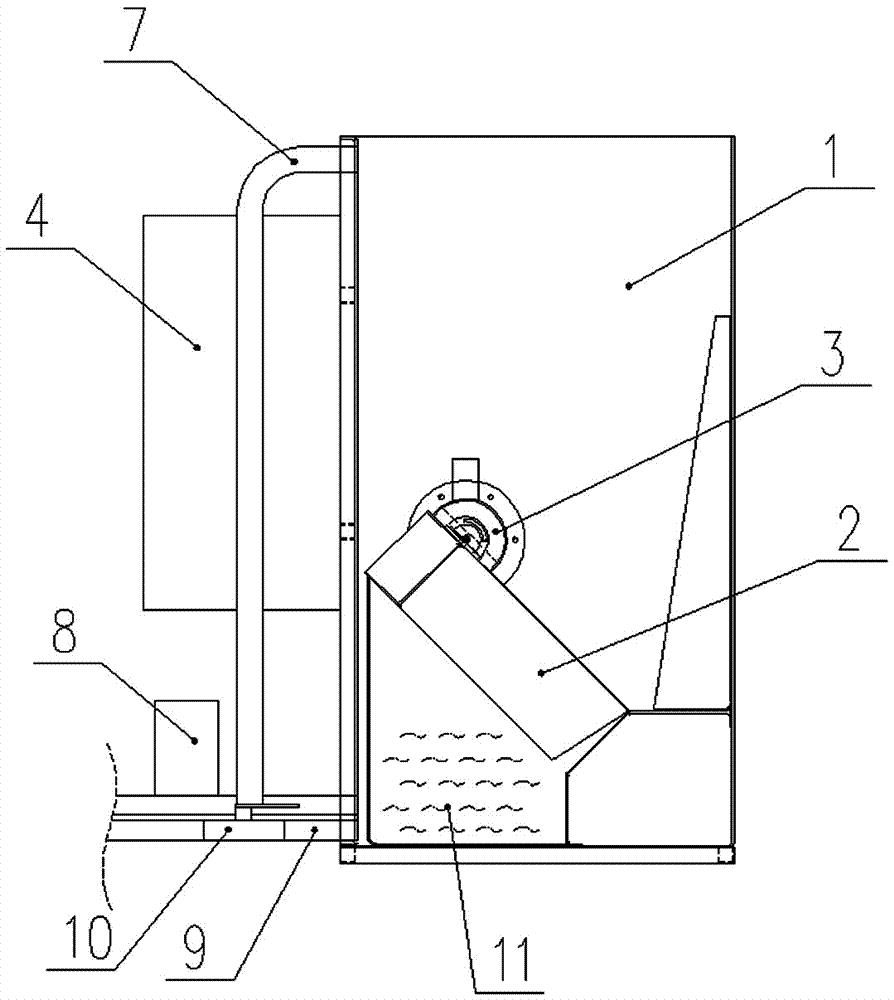

[0012] Example: figure 1 , 2 As shown, the upper end of the water inlet door 2 according to the present invention is provided with a rotary hinge 5, which can make the water inlet door 2 rotate along the rotating shaft, and limit baffles 6 are arranged on both sides, and when the water inlet door rotates, it will be blocked by the limit baffles 6. Blocking to the end face of the analog interface of the water storage tank 1, the water inlet door 2 is closed on the interface of the water storage tank 1 by its own weight; the water storage tank 1 is provided with a water inlet pipe 7, a water inlet control valve 8, and a drain pipe 9 and the drainage control valve 10, by adjusting the control valve, water injection or drainage can be performed into the tank; the angle tester 3 can test the rotation of the water inlet door 2 after being filled with water through the angle tester 3, and at the same time, the liquid level tester 4 can Real-time monitoring of the liquid level of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com