Test device for permeability evolution and spontaneous combustion characteristics of pressure-bearing broken coal

A characteristic test and permeability technology, which is applied in the field of pressure-bearing broken coal permeability evolution and spontaneous combustion characteristics test device, can solve the problems that stress loading cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

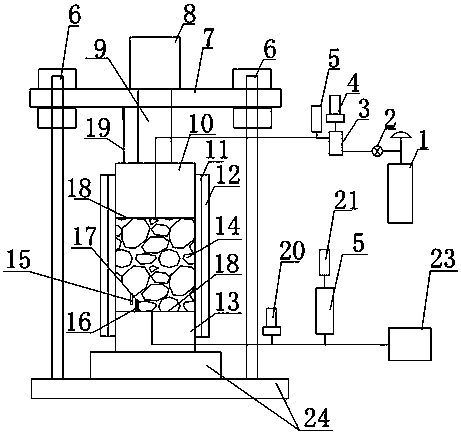

[0033] A test device for permeability evolution and spontaneous combustion characteristics of pressure-bearing crushed residual coal, comprising a heating temperature control device 12, a coal sample chamber 14, a first sensor 15, and a second sensor 16, and the coal sample chamber 14 includes a coal sample chamber cavity Body 11, piston head 10 and lower plug 13, the coal sample chamber cavity 11 is fixed on the support frame of the pressure-bearing broken coal permeability evolution and spontaneous combustion characteristic testing device, the coal sample chamber cavity 11 is a cylinder type hollow structure, put the coal sample into the coal sample chamber cavity 11, the upper part of the coal sample chamber cavity 11 is provided with a piston pressure head 10, and the air inlet built in the piston pressure head 10 is provided with a pipeline connected to the pressure test system. When the gas is oxygen, the oxygen enters the inside of the coal sample chamber cavity 11 throu...

Embodiment 2

[0035] A test device for permeability evolution and spontaneous combustion characteristics of pressure-bearing crushed residual coal, comprising a heating temperature control device 12, a coal sample chamber 14, a first sensor 15, and a second sensor 16, and the coal sample chamber 14 includes a coal sample chamber cavity Body 11, piston head 10 and lower plug 13, the coal sample chamber cavity 11 is fixed on the support frame of the pressure-bearing broken coal permeability evolution and spontaneous combustion characteristic testing device, the coal sample chamber cavity 11 is a cylinder type hollow structure, put the coal sample into the coal sample chamber cavity 11, the upper part of the coal sample chamber cavity 11 is provided with a piston pressure head 10, and the air inlet built in the piston pressure head 10 is provided with a pipeline connected to the pressure test system. When the gas is nitrogen, the nitrogen enters the inside of the coal sample chamber cavity 11 t...

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 1, except that the gas is carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com