Casing axial load testing device during the period for waiting on cement mortar setting

A technology of axial load and test device, applied in the direction of measuring device, measuring force, instrument, etc., can solve problems such as the difference between the force of the test casing and the actual working condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

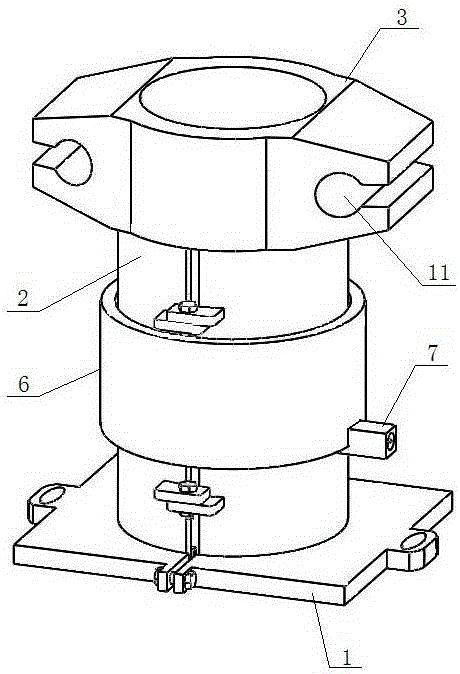

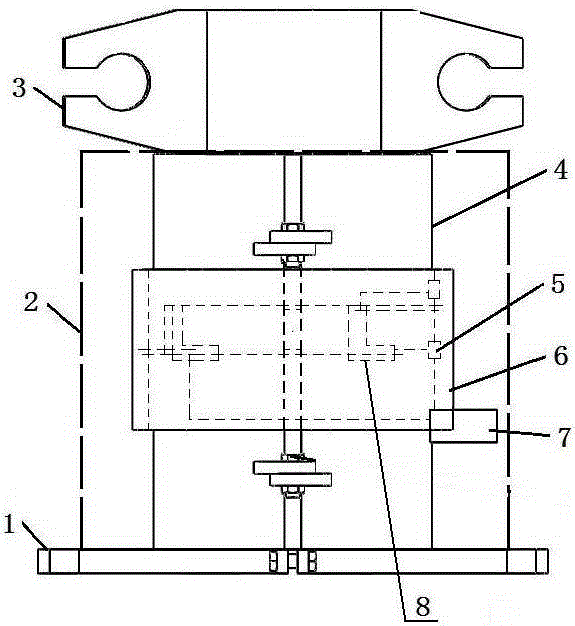

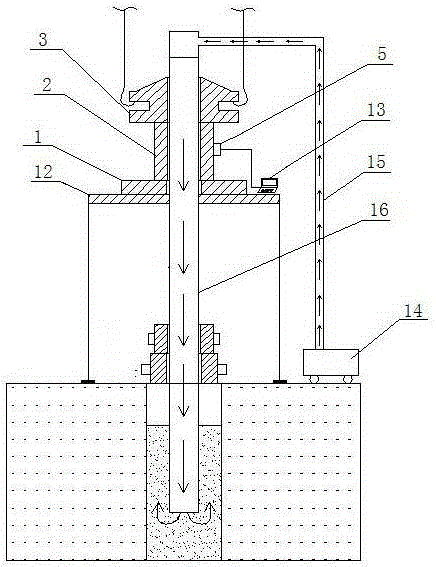

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 , figure 2 As shown, the casing axial load test device during the cement slurry waiting period includes a lower base 1, a sensor 2, and an upper elevator 3. The lower base 1 is fixed on the drilling platform 12, the sensor 2 is fixed on the lower base 1, and the upper elevator 3 sits on the sensor 2, and forms a casing channel through the three; the lower base 1 is installed on the drilling platform 12 during the test, and mainly plays the role of fixing the sensor 2, such as Figure 4 As shown, the lower base 1 is composed of two halves combined together. The inner side of each half has a semi-circular groove, and the outer side of each half is provided with mounting holes. After the two halves are combined, an annular fixing groove is formed. 9 and the central hole 10, the sensor 2 is seated in the fixing groove 9 and fastened by two halves; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com