Measuring device, measuring system and measuring method of continuous metering gas flow meter

The technology of a gas flowmeter and measurement method is applied in the direction of measuring device, liquid/fluid solid measurement, test/calibration device, etc., which can solve the problems of long measurement test time, not wide detection range, and reduced work efficiency, so as to achieve convenient Effect of control and operation, wide detection range, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

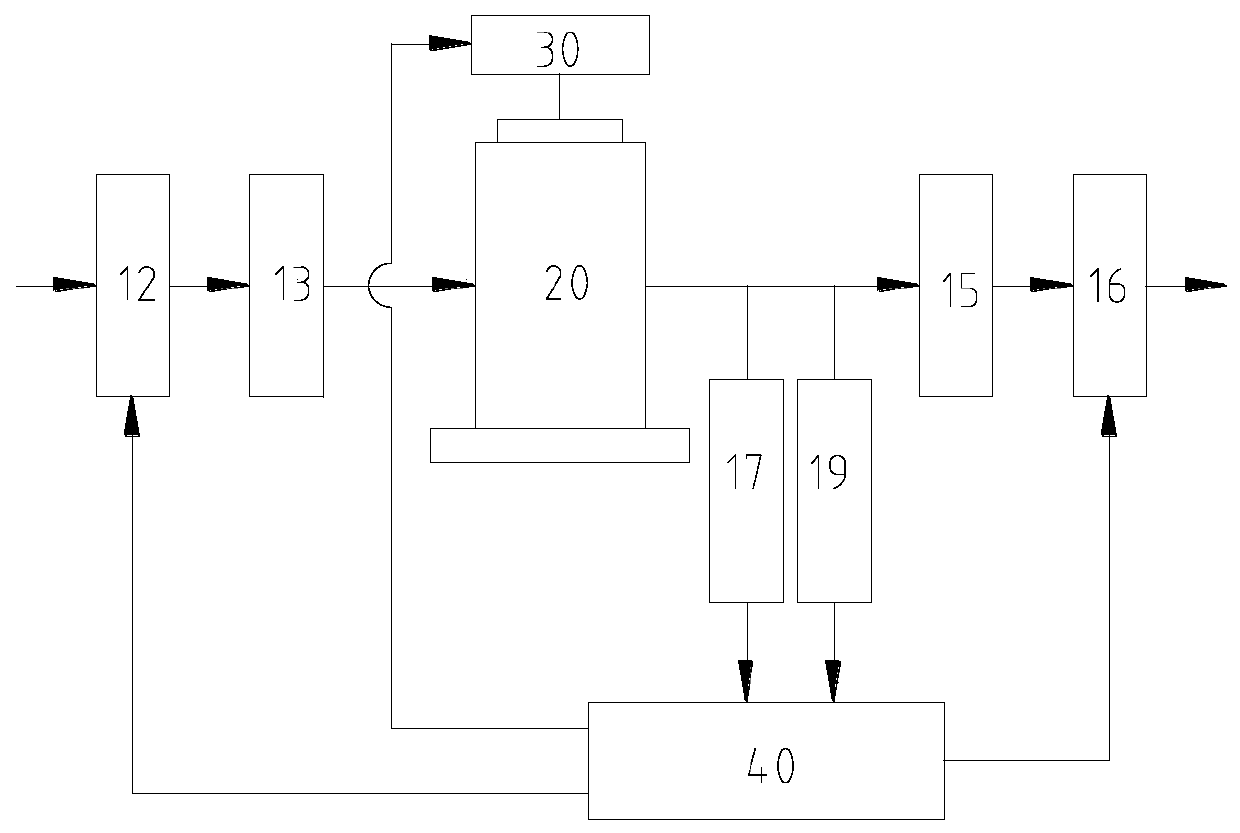

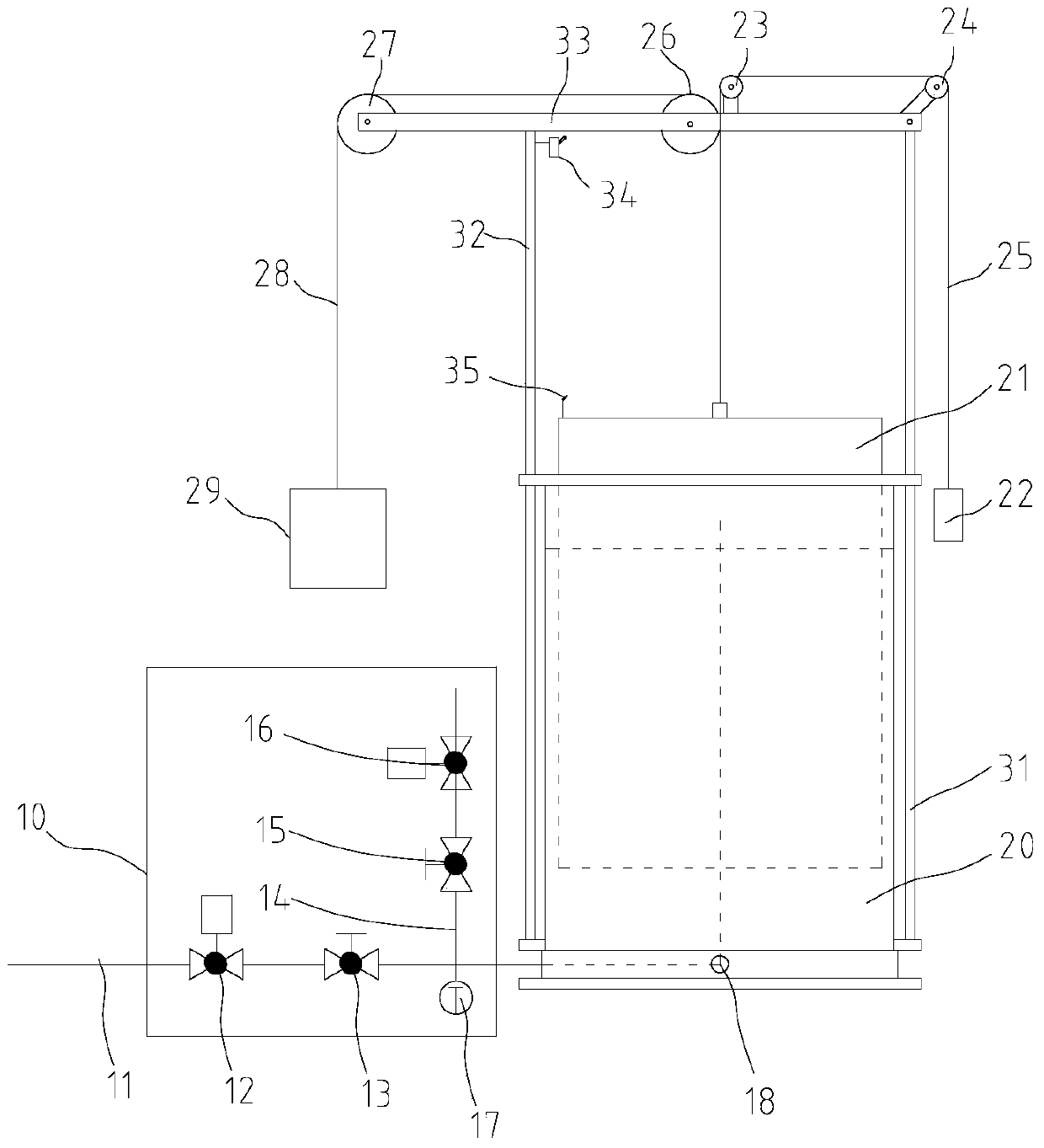

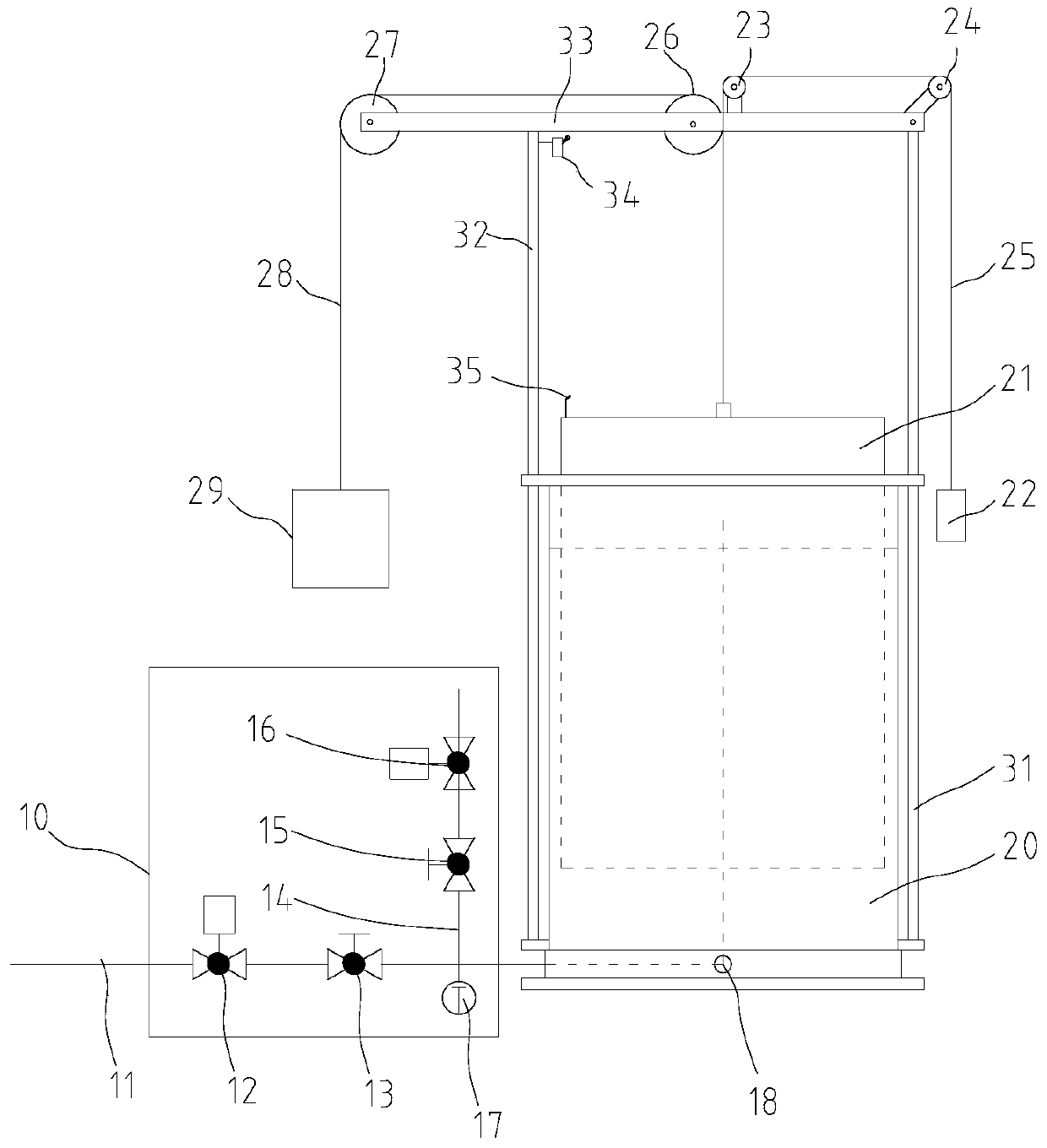

[0056] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a measuring device for continuous metering gas flow meter, including

[0057] A metering cylinder 20, the measuring cylinder 20 is in the shape of a cylinder with an open upper end, the measuring cylinder 20 is provided with a sealing liquid and a buoy 21, the buoy 21 is in the shape of a cylinder with an outer diameter slightly smaller than the inner diameter of the measuring cylinder 20, and the water level of the buoy 21 is The open end is immersed in the sealing liquid;

[0058] A pipeline system 10, which includes an air inlet pipe 11 and an air outlet pipe 14, one end of the air inlet pipe 11 is connected to the output end of the measured flowmeter, and the other end enters the inside of the metering cylinder 20 from the side wall near the bottom of the metering cylinder 20, and The sealing liquid extends upwards into the buoy 21 in a bent shape, and gas is introduced into the ...

Embodiment 2

[0084] The difference between embodiment 2 and embodiment 1 is that structurally embodiment 2 also includes a travel switch 34 and a baffle plate 35, the travel switch 34 is arranged on the upper part of the left column 32, and the upper end of the buoy 21 is arranged at the relative position of the left column 32. The baffle plate 35, the baffle plate 35 is used in conjunction with the travel switch 34, and the travel switch 34 is connected to the computing device 40 for signals;

[0085] The specific differences in the measurement methods are:

[0086] Among the specific detection steps in embodiment 1:

[0087] 1) Pre-detection gas volume Q is set in computing device 40 0 and detection gas volume Q 1 ;

[0088] 6) End of detection: when the gas volume V in the metering cylinder 20 1 When the detected gas volume Q1 in the calculation device 40 is reached, the calculation device 40 controls the intake solenoid valve 12 to close, manually closes the intake ball valve 13 to s...

Embodiment 3

[0093] The difference between Embodiment 3 and Embodiment 1 is that the real-time displacement measuring device is a capacitive displacement sensor installed on the upper beam 33 to detect the displacement of the buoy 21 in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com