Washed fabric twisted flatness testing device and method

A testing device and flatness technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of subjective evaluation being easily affected by personal factors, not considering hand washing and wringing, and the uncertainty of evaluation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below through examples and in conjunction with the accompanying drawings.

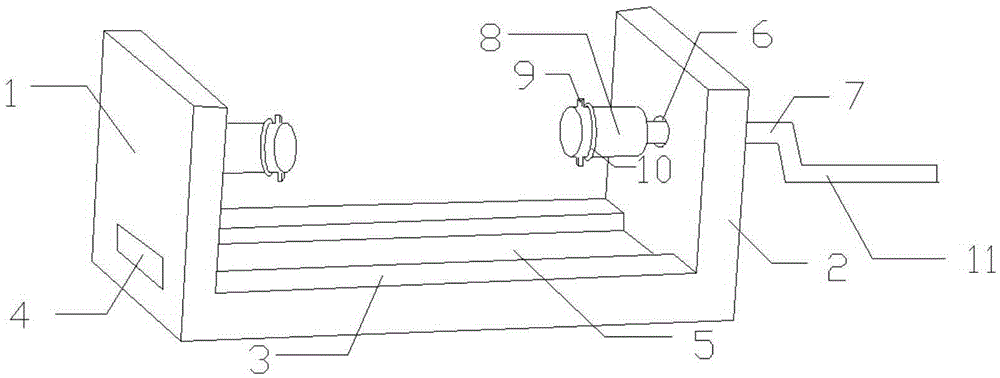

[0032] Such as figure 1 As shown, the test device for twisting flatness of fabric after washing includes a fabric twisting simulation device and an image capture device. The fabric twisting simulation device comprises a first baffle 1, a second baffle 2, a bottom plate 3, a stick 7, a moving cylinder 8, a static cylinder, a positioning pin 9 and a positioning ring 10; the first baffle 1, the second Both the baffle plate 2 and the bottom plate 3 are made of metal. The first baffle and the second baffle are fixed at both ends of the bottom plate. A water outlet 4 is provided at the bottom of the first baffle, and a groove 5 is provided on the upper surface of the bottom plate, and the groove 5 communicates with the water outlet. The center position of the second baffle is provided with a round hole 6; one end of the stic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com