Multi-degree-of-freedom low-frequency vibration-isolation gasket

A degree of freedom and vibration isolation technology, applied in non-rotational vibration suppression and other directions, can solve the problems of inability to achieve effective vibration isolation with multiple degrees of freedom, high cost of vibration isolation gaskets, and achieve the effect of good bearing capacity and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

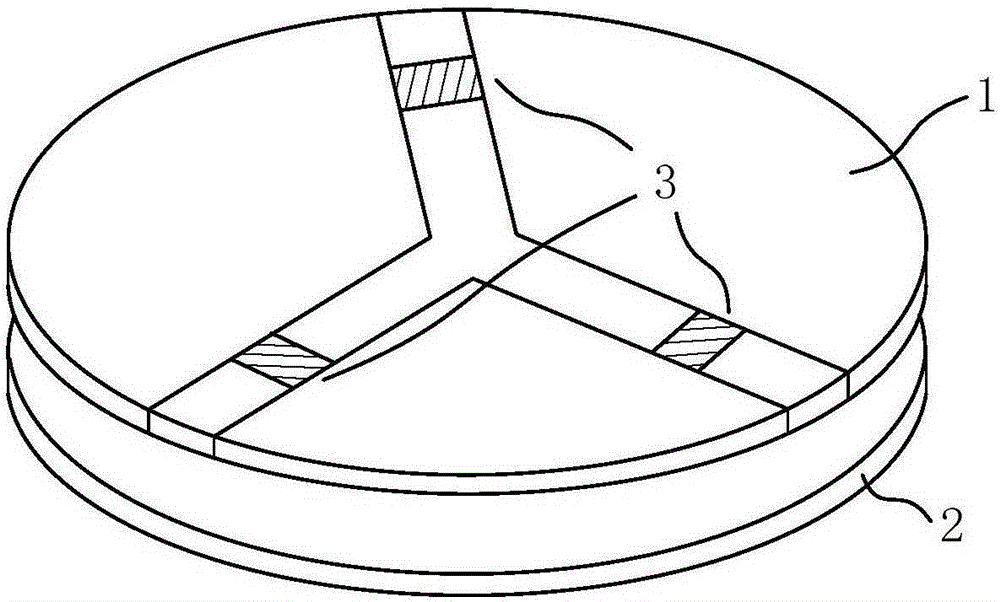

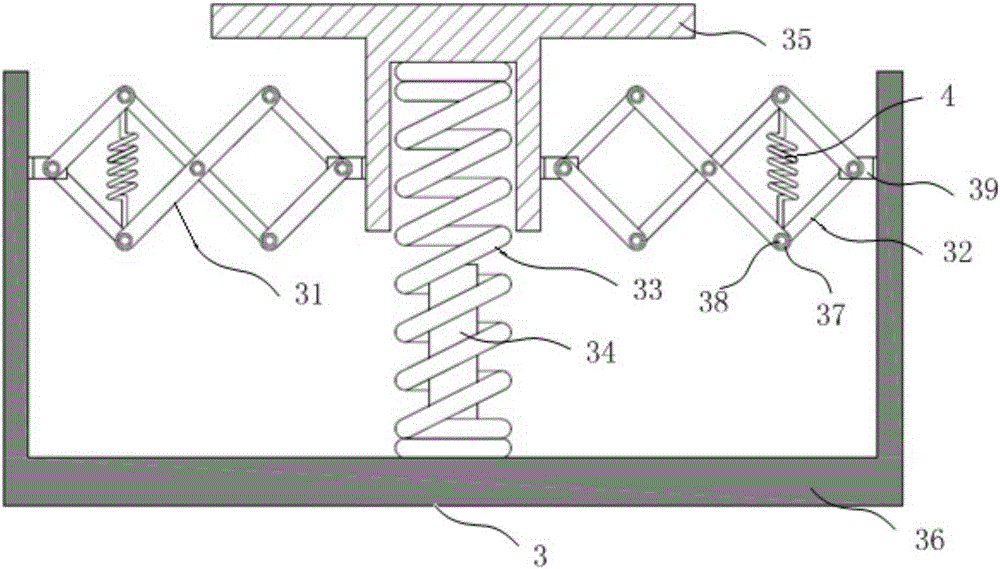

[0022] like Figures 1 to 5 As shown, it is a preferred embodiment provided by the present invention.

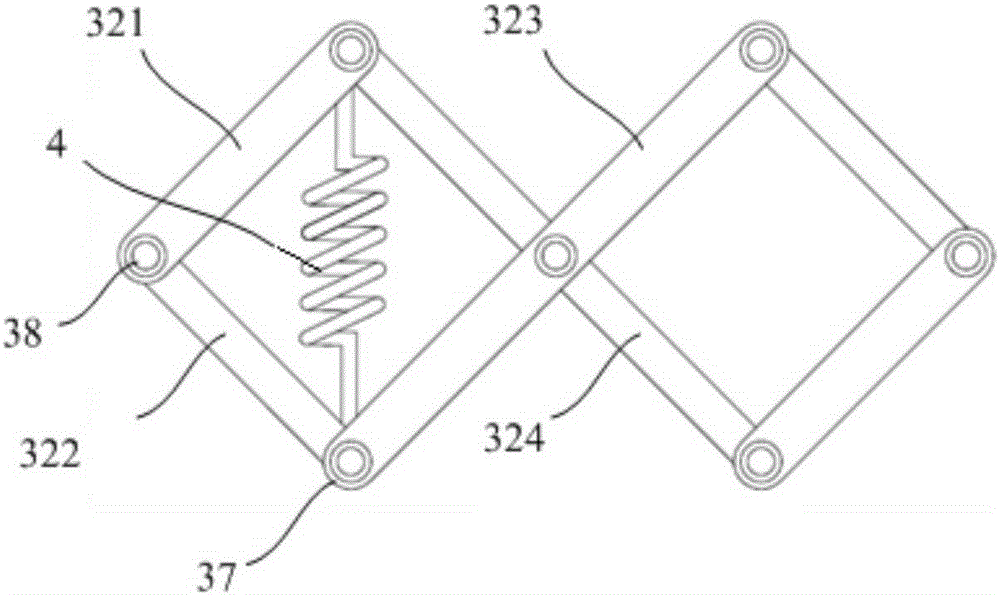

[0023] In this embodiment, a multi-degree-of-freedom low-frequency vibration isolation gasket for a machine tool is provided, including a top plate 1 for contacting the machine tool, a bottom plate 2 located below the top plate 1 and fixed to the ground, and a bottom plate 2 disposed between the top plate 1 and the bottom plate 2 The elastic vibration isolation structure 3. The elastic vibration isolation structure 3 includes a left fork structure 31 and a right fork structure 32 installed between the vibration isolation platform 35 and the base 36, a vertical spring 33 for providing a supporting force, and a vertical spring 33 for fixing the direction of the vertical spring. The vertical guide post 34 fixed on the base 36 and the fork structure support 39 for connecting the fork structures 31 and 32 . The left fork-shaped structure 31 and the right fork-shaped structure 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com