Transmission and transformation electro-vibration adaptive tower

An adaptive, power transmission and transformation technology, applied to towers, earthquake resistance, building components, etc., can solve problems such as endangering power safety, residents' production and living electricity, structural safety and stability, weak construction, uneven settlement, etc., to achieve Prevent foundation cracking and uneven settlement, facilitate mass interchangeable production, avoid damage and power failure accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

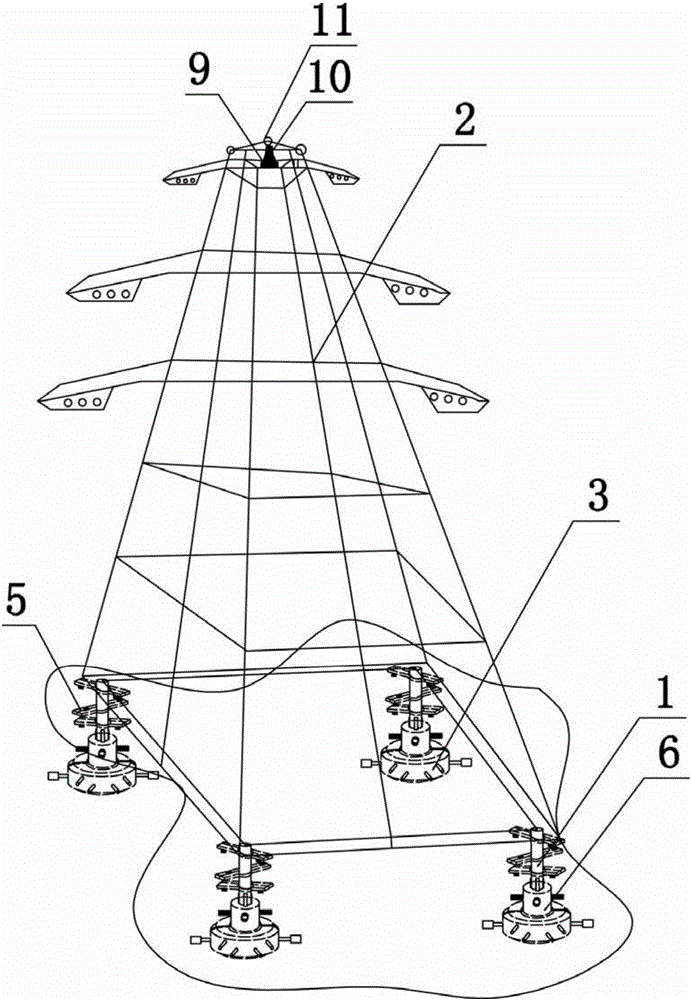

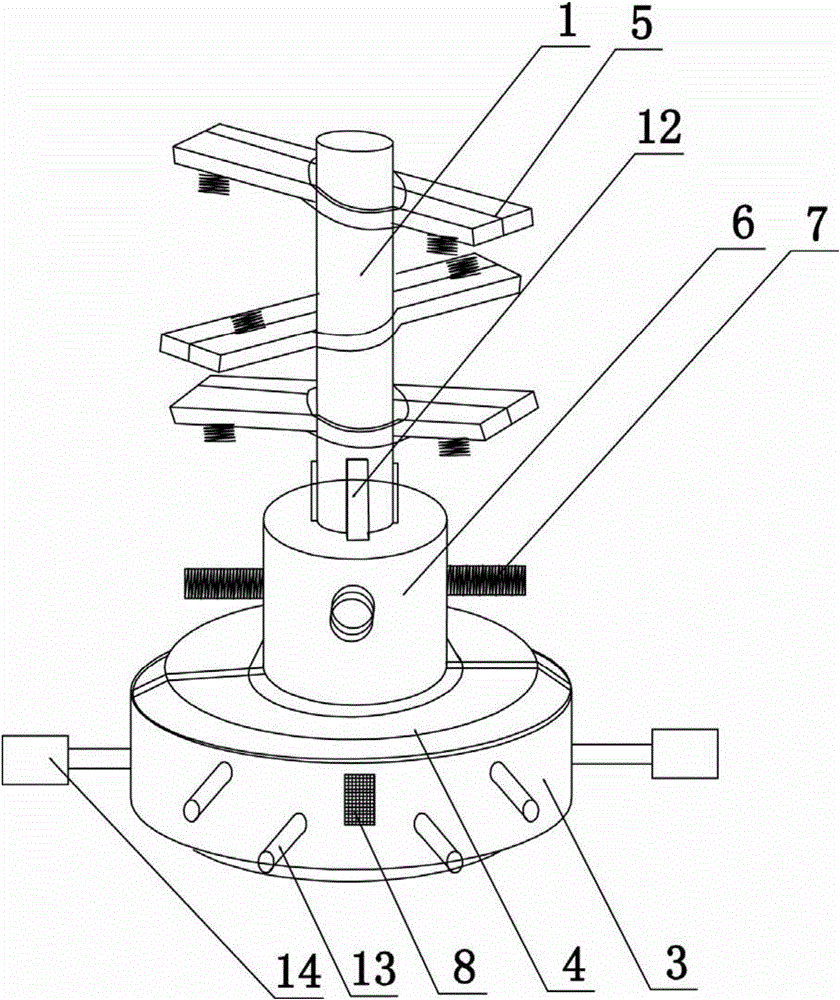

[0015] like figure 1 , figure 2 As shown, a power transmission and transformation vibration adaptive tower includes a tower body 2 with a supporting column 1 at the bottom, an adaptive positioning base and a concrete tower base 3 laid underground, and the adaptive positioning base includes a lower prefabricated The chassis 4 on the concrete tower foundation 3 and the pole holders 5 arranged in a staggered space in several layers, the middle part of the chassis 4 is provided with a load-bearing positioning member 6 supporting the column 1, and the surrounding sides of the load-bearing positioning member 6 and / or the embracing A self-returning spring 7 is provided at the bottom of the pole device 5, a positioning reference module 8 is provided in the concrete tower base 3, and a position acquisition module 10 connected to a controller 9 is provided at the top of the tower body 2, and the controller 9 is connected to an alarm module 11 .

[0016] The pole holder 5 adopts a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com