Pipe gallery prefabricated parts and prefabricated comprehensive pipe gallery

A technology of integrated pipe gallery and prefabricated parts, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of fragile connection structure, inconvenient transportation and hoisting, poor stability of assembly structure, etc., and achieves high installation efficiency, The effect of on-site assembly and construction is less and the structural strength is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

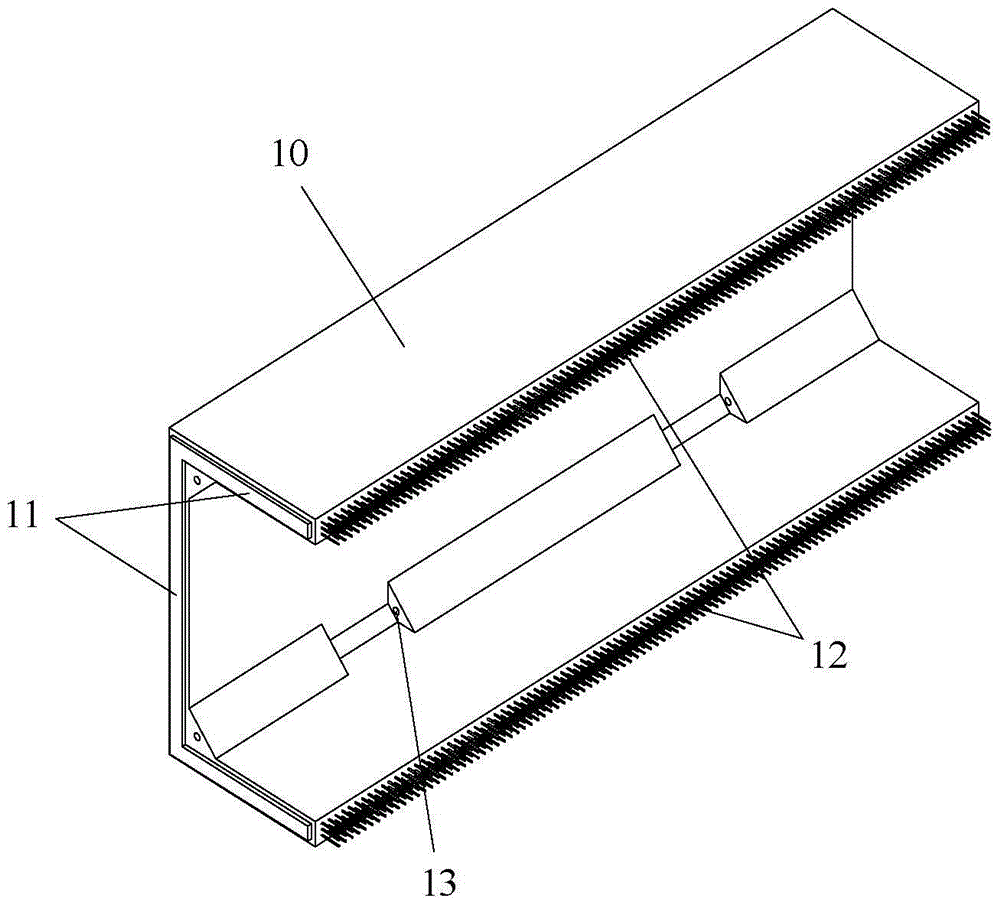

[0045] Such as figure 1 , Figure 5 , Figure 7 , Figure 8 As shown, the pipe gallery prefabricated part of the present invention is a trough prefabricated part 10, and the trough prefabricated part 10 includes a connected web and a flange, reinforcing steel bars arranged inside the web and the flange, and a The connection sealing structure at both ends of the plate and the flange and the longitudinal force-bearing structure arranged longitudinally along the channel prefabricated part, the height of the web meets the requirements for the use of the pipe gallery, and the lateral side of the flange includes the reserved end 12 of the reinforcing steel bar.

[0046] The connection and sealing structure of the trough-shaped prefabricated part 10 in this embodiment is a plug-in structure, and the longitudinal force-bearing structure is a prestressed steel cable connection structure. That is, the connection and sealing structure is a groove 11 arranged at the same end of the web...

Embodiment 2

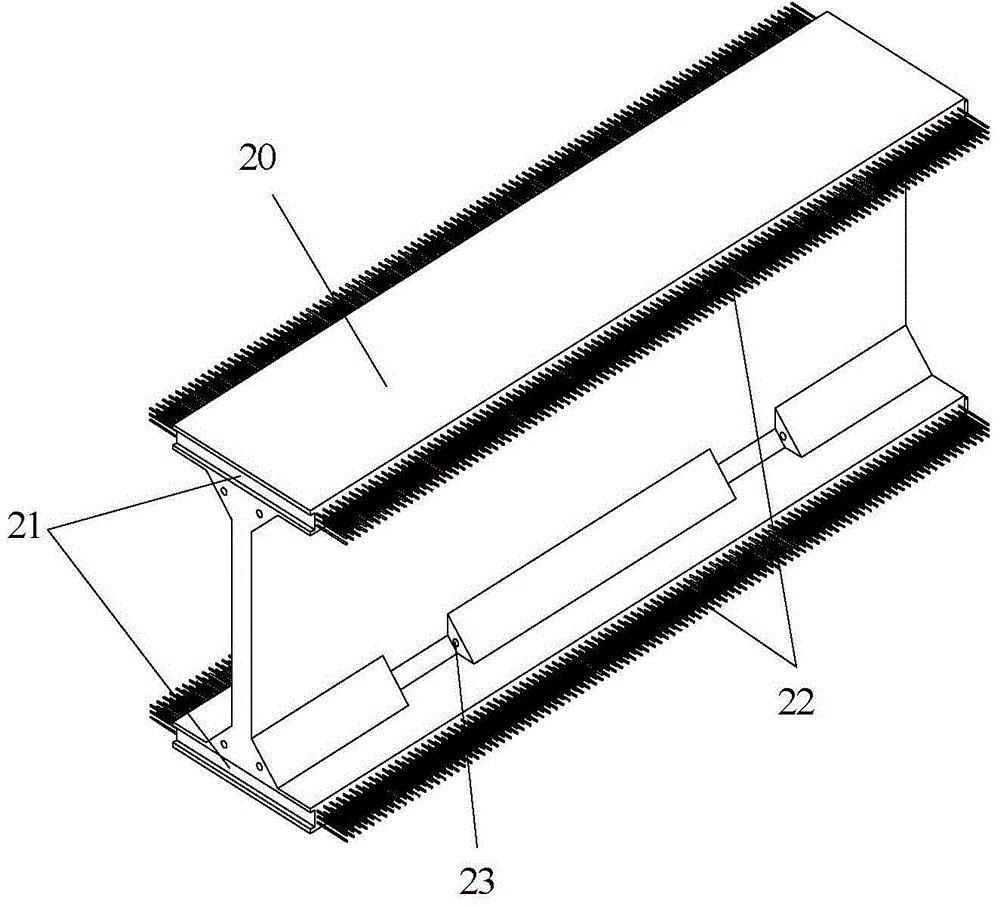

[0050] Such as figure 1 , figure 2 , Figure 5 to Figure 7 , Figure 9 As shown, the prefabricated parts of the pipe gallery in this embodiment are trough-shaped prefabricated parts 10 and I-shaped prefabricated parts 20 .

[0051] The channel preform 10 is as described above.

[0052] The I-shaped prefabricated part 20 includes a connected web and a flange, reinforcing steel bars arranged inside the web and the flange, connecting sealing structures arranged at both ends of the web and the flange, and For the longitudinal force-bearing structure arranged longitudinally, the height of the web satisfies the corresponding connection between the flange and the flange of the channel prefabricated part 10, and the lateral side of the flange includes the reserved end 22 of the reinforcement bar.

[0053] The connection and sealing structure is a plug-in structure, and the longitudinal force-bearing structure is a prestressed steel cable connection structure. That is, the connec...

Embodiment 3

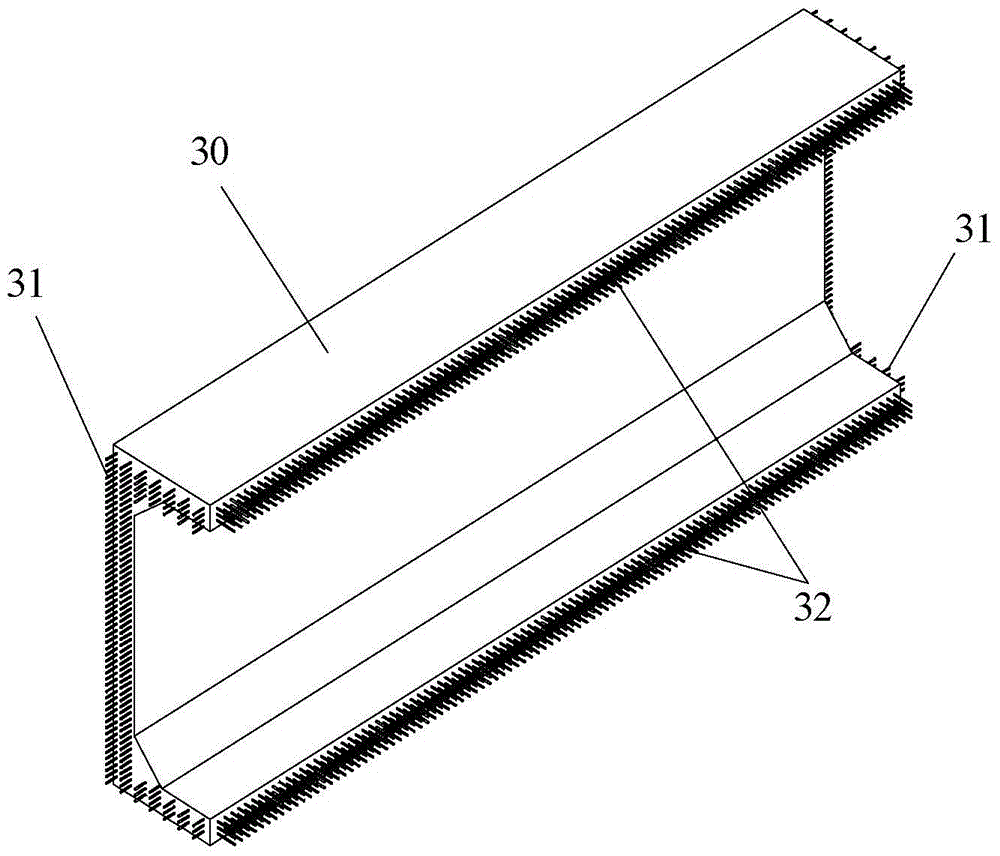

[0057] Such as image 3 As shown, the prefabricated part of the pipe gallery in this embodiment is a trough prefabricated part 30 . The channel prefabricated part 30 includes connected webs and flanges, reinforcing steel bars arranged inside the webs and flanges, connecting sealing structures arranged at both ends of the web and flanges, and The vertically arranged longitudinal force-bearing structure, the height of the web plate meets the requirements for the use of the pipe gallery, and the lateral side of the wing plate includes the reserved end 32 of the reinforcing steel bar.

[0058] The above-mentioned connection sealing structure and longitudinal force-bearing structure are cast-in-place structures for reinforcing steel bar connections. That is, the connection sealing structure and the longitudinal force-bearing structure are the reserved ends 31 of the reinforcing steel bars of the channel prefabricated part 30 at both ends of the web and the flange, and the reserved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com