Device capable of repeatedly utilizing pore water pressure gauges and manufacturing method of device

A pore water piezometer and a technology with holes, which can be used in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problem that the sealing material is difficult to form an effective water-resistant layer, the buried position of the pore water piezometer is not accurate, and the data Does not belong to the same vertical plane, etc., to achieve good water isolation effect, realize recycling and reuse, and facilitate monitoring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

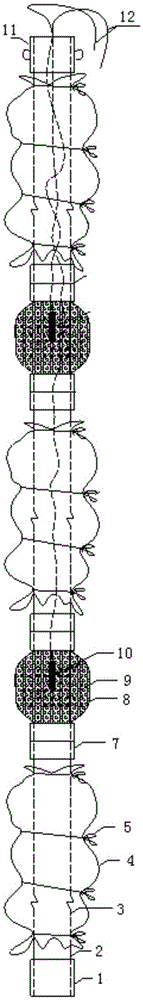

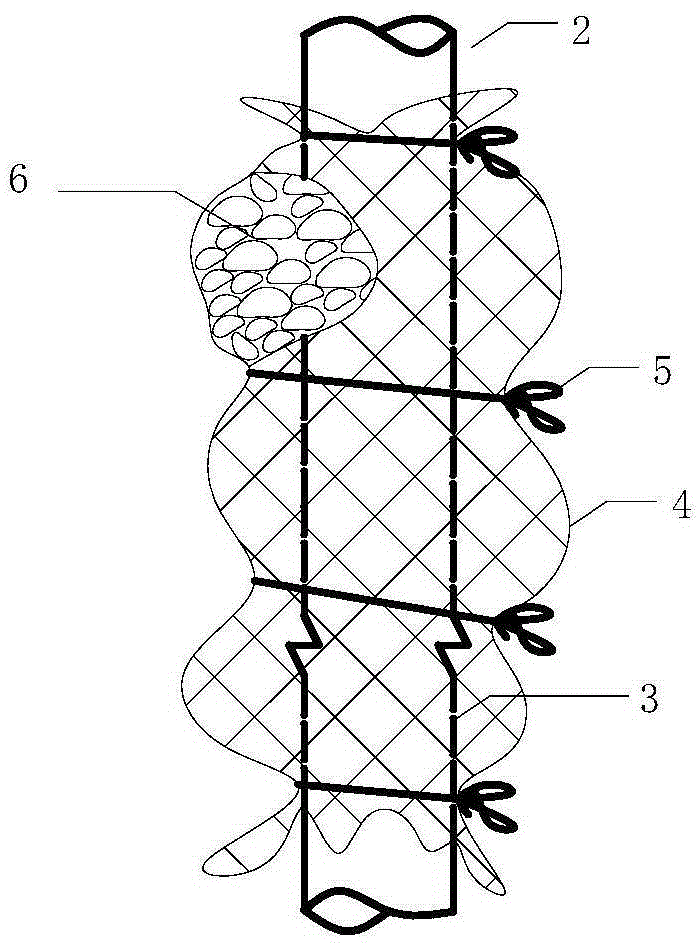

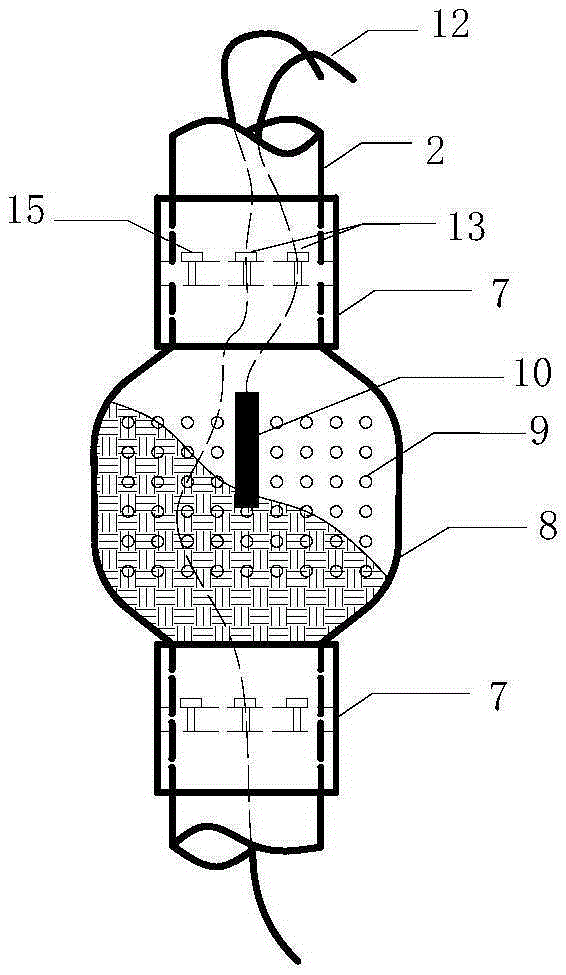

[0036] Such as Figure 1-Figure 3 As shown, the present invention discloses a device for reusing a pore water pressure gauge, which includes a plurality of steel pipes 2 arranged vertically from top to bottom, and a filter pipe 8 is vertically arranged between adjacent two steel pipes 2, The upper and lower ends of each filter pipe 8 are respectively connected and fixed with two connecting sleeves 7 and two steel pipes 2 adjacent to the filter pipe 8 to form the pipe body structure of the whole device, and the bottom of the steel pipe at the lowest end of the pipe body structure A closed bottom sleeve 1 is provided, and the structure of the bottom sleeve 1 is as follows: Figure 5 Shown; the top of the steel pipe at the uppermost end of the pipe structure is provided with a top sleeve 11, each filter pipe 8 side walls of the pipe structure are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com