Extracting method of sisal hemp pectin

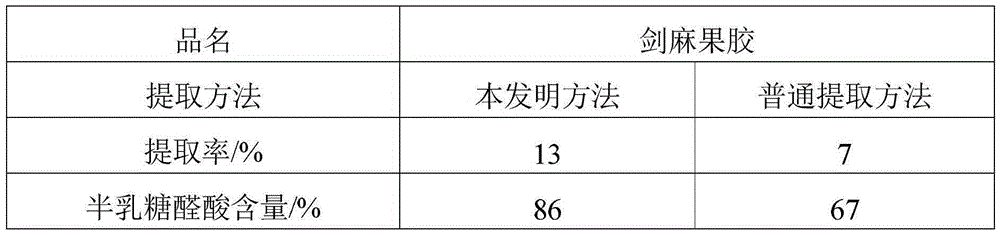

An extraction method and pectin technology, which is applied in the field of sisal pectin extraction, can solve the problems of large acid pollution and low extraction rate, and achieve the effects of complete extraction, stable product quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, after pulverizing 10 parts by weight of sisal slag, divide it into two parts, one part is 2 parts by weight of sisal slag, the other part is the remaining sisal slag, add 8 parts by weight of deionized water, boiled for 5 minutes, cooled to obtain the first mixed solution, added 40 parts by weight of deionized water to the remaining sisal residue, boiled for 8 minutes, and obtained the second mixed solution after cooling.

[0031] The first mixed solution and the second mixed solution are respectively treated by the same high-voltage pulse electric field, the electric field strength is 35kV / cm, the temperature is 60°C, the treatment time of the first mixed solution is 50μs, and the treatment time of the second mixed solution is 200μs , after processing, proceed to the second step.

[0032] Step 2, after adjusting the pH of the first mixed solution with citric acid to be 5, add galactose in the first mixed solution, inoculate brewer's yeast, the inoculum size is ...

Embodiment 2

[0038] Step 1, after pulverizing 10 parts by weight of sisal slag, divide it into two parts, one part is 3 parts by weight of sisal slag, the other part is the remaining sisal slag, add 12 parts by weight of deionized water was boiled for 8 minutes, cooled to obtain the first mixed solution, 60 parts by weight of deionized water was added to the remaining sisal residue, boiled for 15 minutes, and the second mixed solution was obtained after cooling.

[0039] The first mixed solution and the second mixed solution are respectively treated by the same high-voltage pulse electric field, the electric field strength is 35kV / cm, the temperature is 60°C, the treatment time of the first mixed solution is 50μs, and the treatment time of the second mixed solution is 200μs , after processing, proceed to the second step.

[0040] Step 2, after adjusting the pH of the first mixed solution with citric acid to be 6, add galactose in the first mixed solution, inoculate brewer's yeast, the inocul...

Embodiment 3

[0046] Step 1, after pulverizing 10 parts by weight of sisal slag, divide it into two parts, one part is 2 parts by weight of sisal slag, the other part is the remaining sisal slag, add 10 parts by weight of deionized water was boiled for 7 minutes, cooled to obtain the first mixed solution, 50 parts by weight of deionized water was added to the remaining sisal residue, boiled for 10 minutes, and the second mixed solution was obtained after cooling.

[0047] The first mixed solution and the second mixed solution are respectively treated by the same high-voltage pulse electric field, the electric field strength is 35kV / cm, the temperature is 60°C, the treatment time of the first mixed solution is 50μs, and the treatment time of the second mixed solution is 200μs , after processing, proceed to the second step.

[0048] Step 2, after adjusting the pH of the first mixed solution with citric acid to be 6, add galactose in the first mixed solution, inoculate brewer's yeast, the inoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com