Canal slope cast-in-place concrete composite additive and preparation method thereof

A technology of concrete and additives, which is applied in the field of building materials, can solve the problems of large leakage loss, low early strength, and poor impermeability, and achieve the effects of reducing water-cement ratio, improving early strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

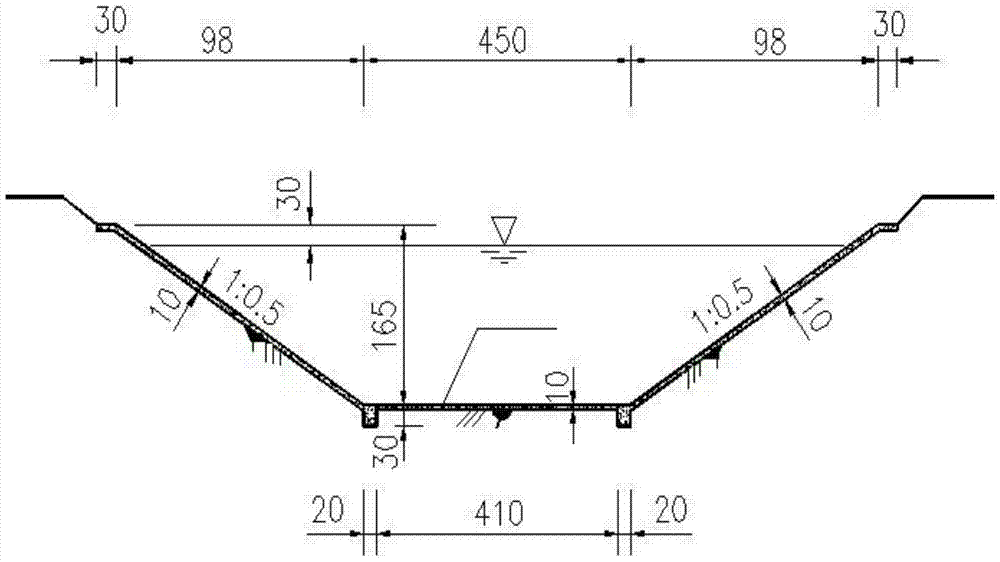

Image

Examples

Embodiment 1

[0026] A composite additive for cast-in-place concrete on channel slopes is composed of the following raw materials: by weight, 40 parts of calcium lignosulfonate water reducing agent, 10 parts of naphthalene series, 1 part of dodecylbenzenesulfonic acid 5 parts of thickener carboxymethyl cellulose, 5 parts of early strength agent methanol and 60 parts of tap water.

[0027] Preparation method: turn on the electric mixer, control the speed of 60r / min, and mix the raw materials in the following order by weight: 50 parts of water reducing agent, 1 part of air-entraining agent, 5 parts of thickener, 5 parts of early strength agent, and 60 parts of tap water in order Put it into the mixer and stir continuously for 40 minutes to get the composite additive for cast-in-place concrete on channel slope.

Embodiment 2

[0029] A compound additive for cast-in-place concrete on channel slopes is composed of the following raw materials: 40 parts by weight of naphthalene water reducing agent, 2 parts of air-entraining agent dodecylbenzenesulfonic acid and 3 parts of triterpene saponins Mixing, 10 parts of thickener polyacrylamide, 10 parts of early strength agent methanol, 5 parts of ethanol and 45 parts of tap water.

[0030] Preparation method: turn on the electric mixer, control the speed of 80r / min, and mix the raw materials in the following order by weight: 40 parts of water reducing agent, 5 parts of air-entraining agent, 10 parts of thickener, 15 parts of early strength agent, and 45 parts of tap water in order Put it into the mixer and stir continuously for 25 minutes to get the composite additive for cast-in-place concrete on channel slope.

Embodiment 3

[0032] A compound additive for cast-in-place concrete on channel slopes is composed of the following raw materials: 30 parts by weight of water reducing agent sulfamate, 2 parts of air-entraining agent rosin thermopolymer, and 10 parts of thickener sodium polyacrylate 15 parts and 2 parts of carboxymethyl cellulose, 15 parts of early strengthening agent triethanolamine and 40 parts of tap water.

[0033] Preparation method: turn on the electric mixer, control the speed of 70r / min, and mix the raw materials in the following order by weight: 30 parts of water reducer, 2 parts of air-entraining agent, 12 parts of thickener, 15 parts of early strength agent, and 40 parts of tap water in order Put it into the mixer and stir continuously for 30 minutes to get the composite additive for cast-in-place concrete on channel slope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com