Fermented milk that does not undergo increase in acid level, and method for producing same

A manufacturing method and technology for fermented milk, applied in the directions of microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve the problems of rising acidity, unchanged quality of fermented milk, difficulties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

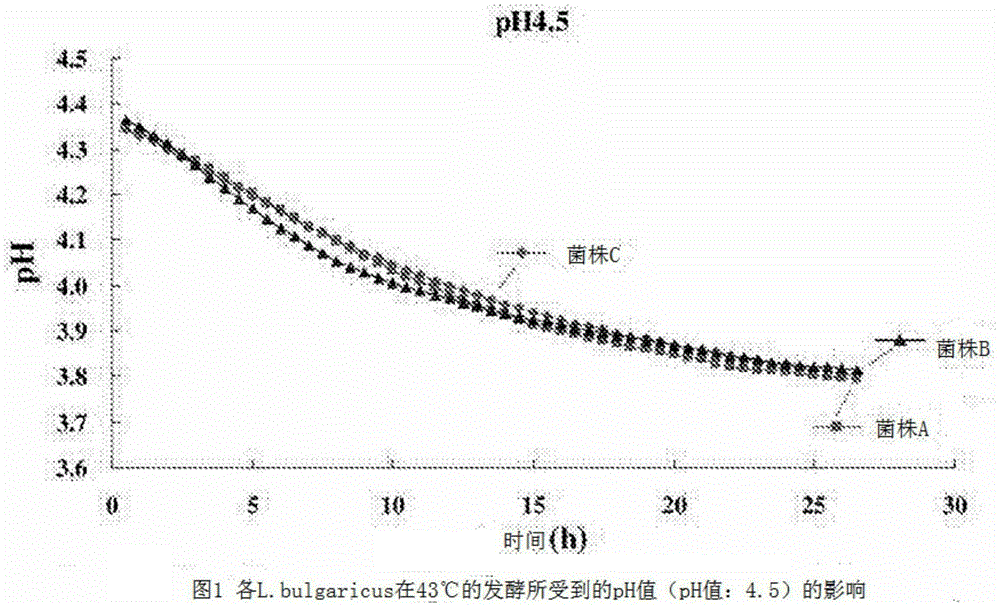

[0143] [Example 1] Screening of acid-sensitive lactic acid-producing bacteria

[0144] ◆Preparation method of skim milk medium (pH value: 4.5, pH value: 4.25, pH value: 4.0)

[0145] Skim milk powder, water, lactic acid, and sugar solution (pectin) were mixed to prepare a skim milk powder medium (solid content of non-fat milk: 9.5% by weight, fat content: 0.1% by weight) having a pH of 4.5. After homogenizing (homogenizing) the skimmed milk powder medium and stabilizing it with pectin, commercially available lactic acid (50% by weight, Wako Pure Chemical Industries, Ltd., Japan: special grade reagent) was added to prepare the pH Unsterilized medium with a value of 4.25 and a pH of 4.0. By preparing the medium in this way, caking can be suppressed along with the adjustment of the pH of the medium containing the milk component. These media were used for the test after heat sterilization at 95° C. for 5 minutes, respectively.

[0146] ◆Preparation of lactic acid producing bact...

Embodiment 2

[0173] [Example 2] Production of fermented milk (yogurt)

[0174] The mixed starter obtained by mixing Lactobacillus bulgaricus and Streptococcus thermophilus used in Example 1 was cultured using a skim milk powder medium (skim milk powder: 10% by weight, water: 90% by weight, sugar: 2% by weight) . It mixed with the raw material of fermented milk (skimmed milk powder: 12.4 weight%, unsalted butter: 0.4 weight%, sugar: 5.4 weight%, water: 81.84 weight%), and prepared the raw material mixture. The obtained raw material mixture was heat-sterilized at 95 degreeC for 2 minutes, and then cooled to 45 degreeC. In the obtained raw material mixture, 2% by weight of each starter used in the test was inoculated, and fermentation was carried out at 43°C. When the acidity reaches 0.73%, the fermentation is completed and cooled to 10°C to obtain fermented milk. And these fermented milks were stored in refrigeration (10 degreeC). Here, acidity and pH were measured by conventional method...

Embodiment 3

[0179] [Example 3] Comparison of the ability of starter

[0180] In the same manner as in Example 2, fermented milk was obtained using a commercially available mixed starter YO-MIX863 (DANISCO) with low post-acidification. In addition, three types of fermented milk were obtained by using a mixed starter composed of OLL1171 strain and Streptococcus thermophilus and changing various conditions. Then, these fermented milks were refrigerated (10 degreeC), and various analyzes were performed on the 1st day, the 7th day, and the 10th day. In addition, in the deoxygenation treatment step, nitrogen substitution is performed after sterilization until the oxygen (dissolved oxygen concentration) in the raw material mixture becomes 5 ppm or less. Here, acidity and pH were measured by conventional methods, and Table 2 shows the analysis results on the first day, the seventh day, and the tenth day. In addition, the number of live bacteria of Lactobacillus bulgaricus (L.bulgaricus: LB) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com