Super surface quarter wave plate based on surface plasmon polariton

A surface plasmon and metasurface technology, applied in optical elements, polarizing elements, optics, etc., can solve the problems of large thickness, difficult processing, and narrow waveband, and achieve the effect of thin thickness, low processing difficulty, and wide waveband.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

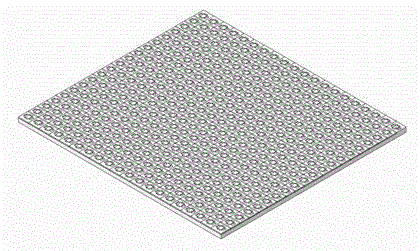

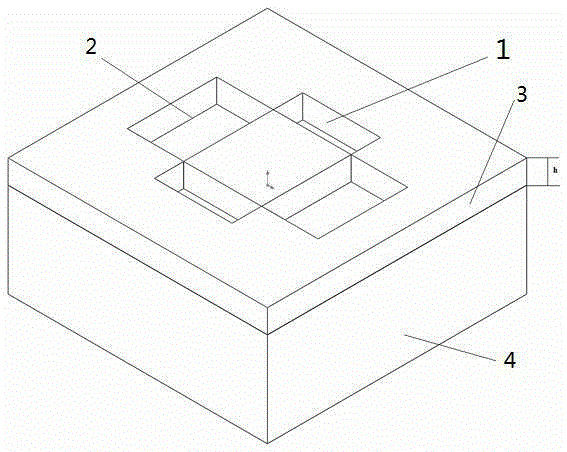

[0048] Embodiment one: see figure 1 As shown, a metasurface quarter-wave plate based on surface plasmons, the wave plate includes a rectangular substrate and a silver film arranged on the rectangular substrate, the silver film is composed of a number of periodic arrays of aperture units, each The aperture units are equipped with two horizontal apertures symmetrical up and down and two longitudinal apertures symmetrical about the left and right centers. There is an intersection.

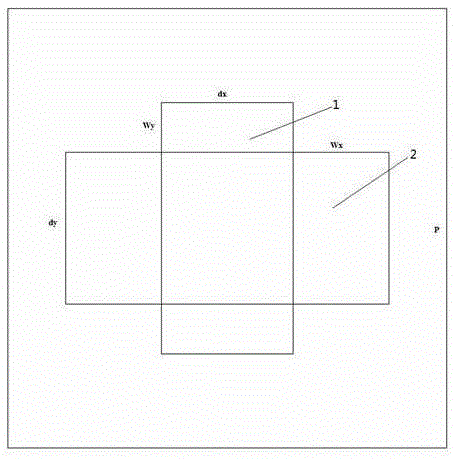

[0049] Such as figure 2 , image 3 As shown, the basic structure of the aperture unit includes a silver film with an aperture and a corresponding substrate, and the center-to-center distance between adjacent aperture units is P, that is, the period of the aperture unit can also be represented by P, that is, the side length of the aperture unit is p.

[0050] The working wavelength of the present invention is 1400nm to 1700nm.

[0051] In this embodiment, the rectangular substrate is a rectangula...

Embodiment 2

[0059] Embodiment 2: The parameters selected in this embodiment are dx=165nm, dy=190nm, P=550nm, Wx=120nm, Wy=60nm, h=50nm, and the maximum aspect ratio is 0.83, see Figure 18 As shown, the schematic diagram of the phase and phase difference curves in the X direction and Y direction under the irradiation of the transmitted light wavelength 1400-1700nm, where the solid line is the phase difference between the X-direction component and the Y-direction component of the transmitted light, and the dotted line is the Y-direction of the transmitted light The phase of the component, the dotted line is the phase of the X-direction component of the transmitted light, it can be calculated that when the wavelength λ=1550nm, the phase difference is 1.472, see Figure 19 As shown, it is a schematic diagram of the transmittance curve of the second embodiment under the irradiation of the transmitted light wavelength 1400-1700nm. It can be seen that when the transmitted light wavelength λ=1550...

Embodiment 3

[0060] Embodiment 3: The parameters selected in this embodiment are dx=155nm, dy=200nm, P=550nm, Wx=120nm, Wy=60nm, h=68nm, and the maximum aspect ratio is 1.13, see Figure 20 As shown, the schematic diagram of the phase and phase difference curves in the X direction and Y direction under the irradiation of the transmitted light wavelength 1400-1700nm, where the solid line is the phase difference between the X-direction component and the Y-direction component of the transmitted light, and the dotted line is the Y-direction of the transmitted light The phase of the component, the dotted line is the phase of the X-direction component of the transmitted light, it can be calculated that when the wavelength λ=1550nm, the phase difference is 1.601, see Figure 21 As shown, it is a schematic diagram of the transmittance curve of the second embodiment under the irradiation of the transmitted light wavelength 1400-1700nm. It can be seen that when the transmitted light wavelength λ=1550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com