Pouring carbon plastic large spherical reflection lens and production method

A technology of spherical mirrors and mirrors, which is applied in mirrors, installations, optics, etc., can solve the problems of poor plastic film surface deformation, heavy product weight, and poor maintainability, and achieve short manufacturing cycles, good optical performance, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

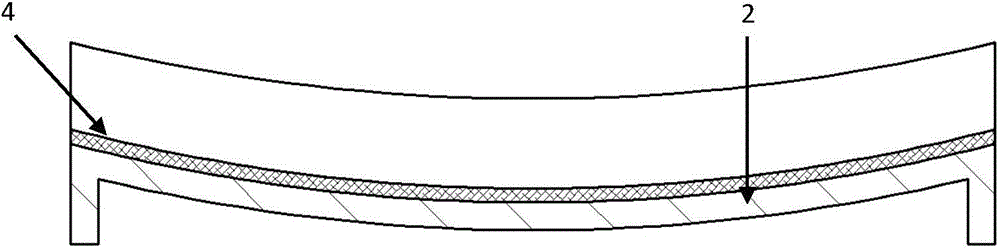

[0023] Polymerized carbon-plastic composite large-scale spherical mirror, the radius of curvature R is 3000 mm, the thickness of the mirror substrate is 20 mm, the geometric size is 40 degrees for the vertical center angle, and 36 degrees for the horizontal center angle. The spherical mold substrate 1 of R3000 is first thermally formed with 20 mm thick silicon glass, and the convex surface of the spherical mold substrate 1 is ground and polished to an optical level on a mirror grinder, with an optical error of 2 to 5 apertures. The mirror seat 2 of the spherical reflector is a composite structure of pre-impregnated epoxy resin carbon fiber cloth and aluminum honeycomb. Five layers of pre-impregnated carbon fiber cloth, five layers of pre-impregnated glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com