Assembly clamper for sandwich structure board lateral compression test

A technology for assembling fixtures and sandwich structures, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult center alignment, secondary damage of the test piece, and the deflection cannot be maintained in the compression loading condition, etc., to achieve easy adjustment. , high safety, convenient assembly and loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

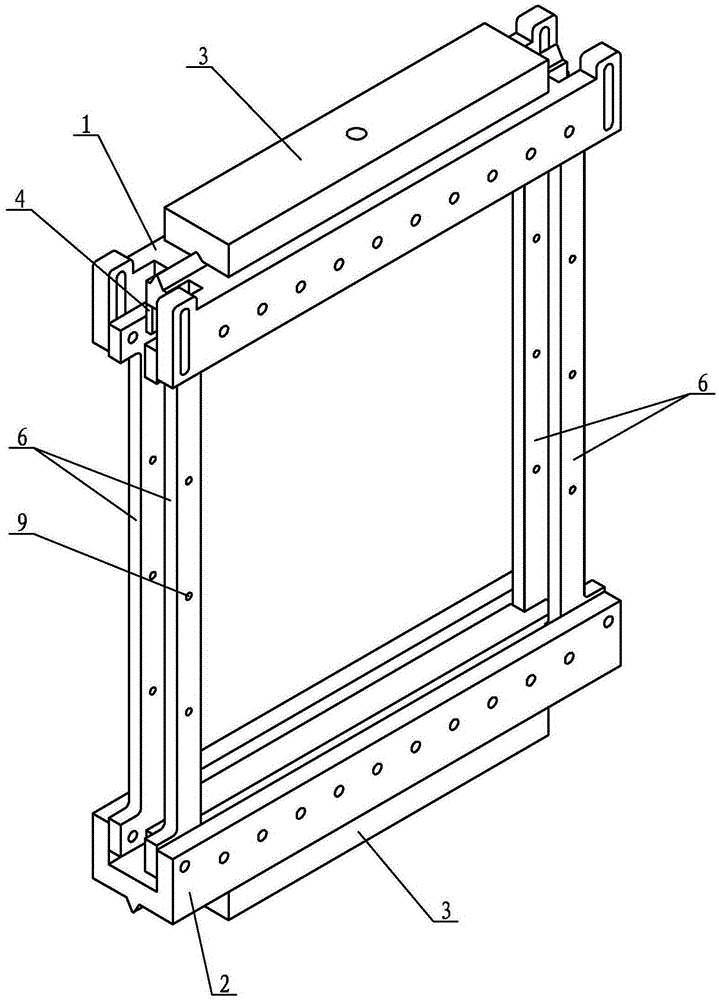

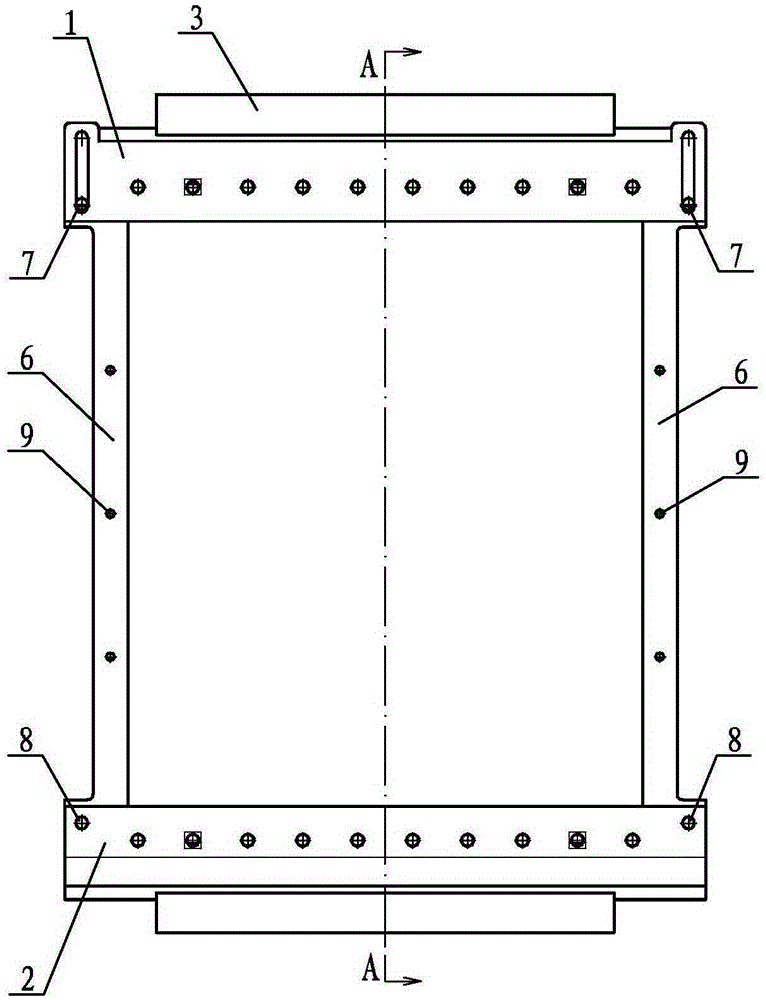

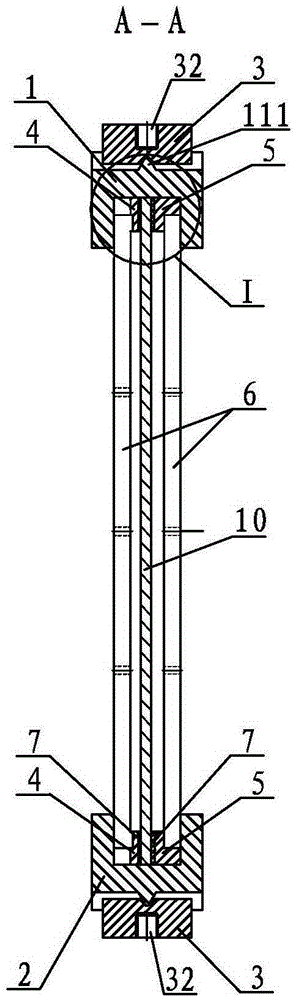

[0039] Specific implementation mode one: combine Figure 1 to Figure 21 Describe this embodiment, this embodiment includes upper chuck 1, lower chuck 2, two end plates 3, two general pads 4, two adjustment pads 5, two long hole connecting elements 7, two round Hole connection element 8, four vertical limit plates 6 and limit connection element 9,

[0040] The cross-section of the upper chuck 1 is H-shaped, which is convenient to be placed horizontally in the opposite direction during assembly. The upper end of the transverse side of the upper chuck 1 is a shallow groove 11, and the lower end is a deep groove 12. The bottom surface of the shallow groove 11 is along the length direction of the central axis. An upper cone flute 111 is provided, and several first upper threaded holes 13 are provided along the length direction on one vertical side of the upper chuck 1 corresponding to the deep groove 12, and the other of the upper chuck 1 corresponding to the deep groove 12 One ve...

specific Embodiment approach 2

[0046] Specific implementation mode two: combination image 3 Describe this embodiment, the width of the deep groove 12 of the upper chuck 1 of this embodiment is equal to the width of the U-shaped groove of the lower chuck 2 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0047] Specific implementation mode three: combination Figure 9 The present embodiment will be described. The taper angle α of the upper tapered flute 111 of the present embodiment is 60°. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com