A cloth splicing stitching folder and a cloth splicing method

A bridle and patchwork technology, applied in the field of clothing manufacturing, can solve the problems of complex structure of auxiliary tooling for placket forming, unable to maintain the same width, uneven wiring, etc., and achieve the effects of simple structure, neat wiring and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific embodiments.

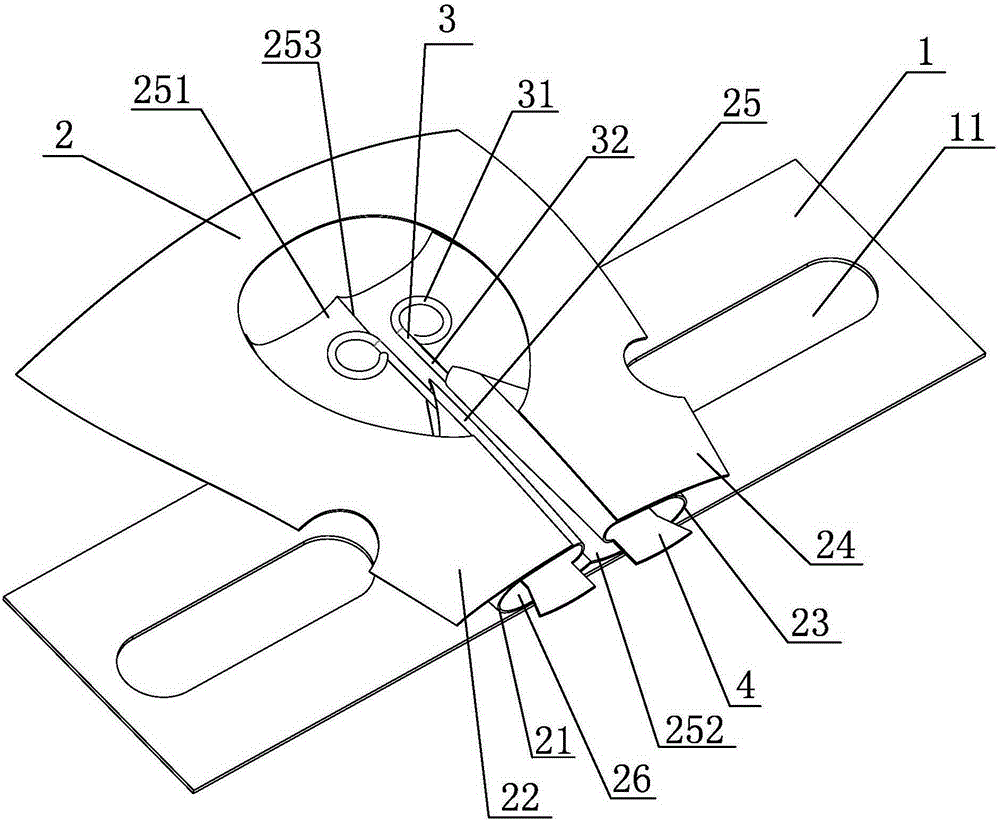

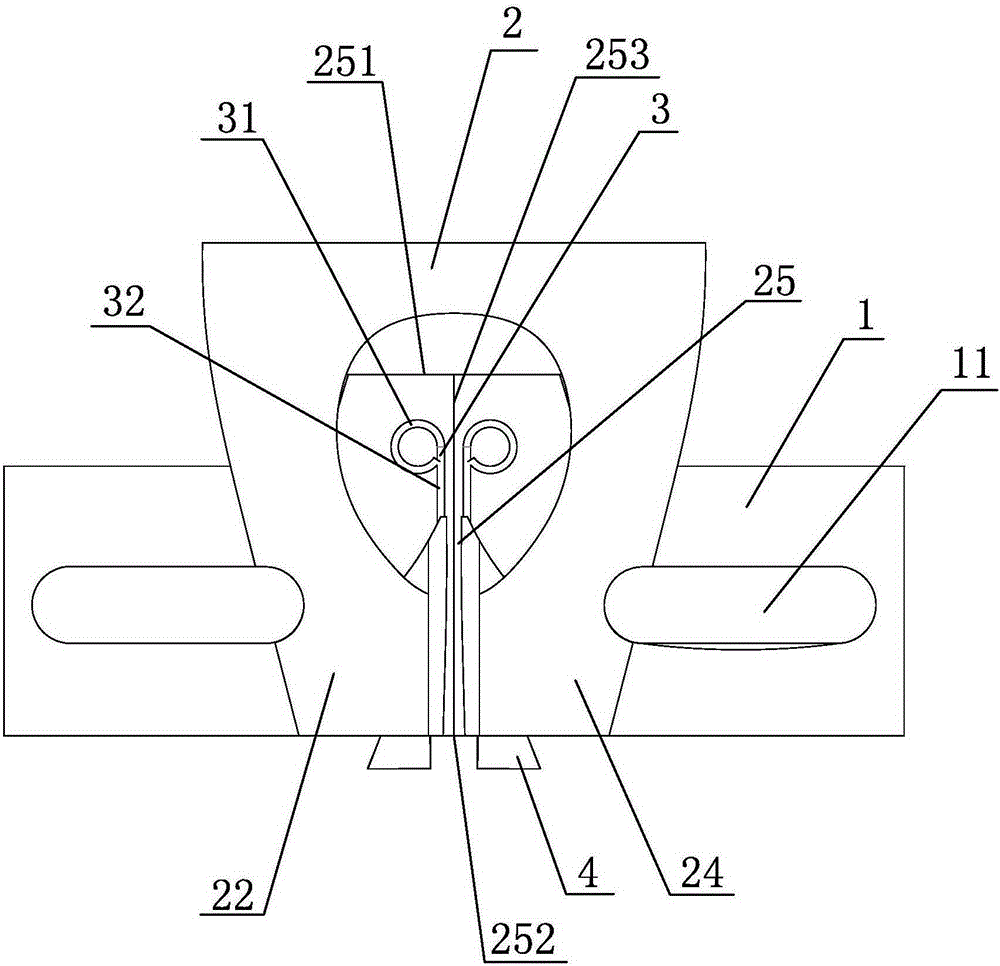

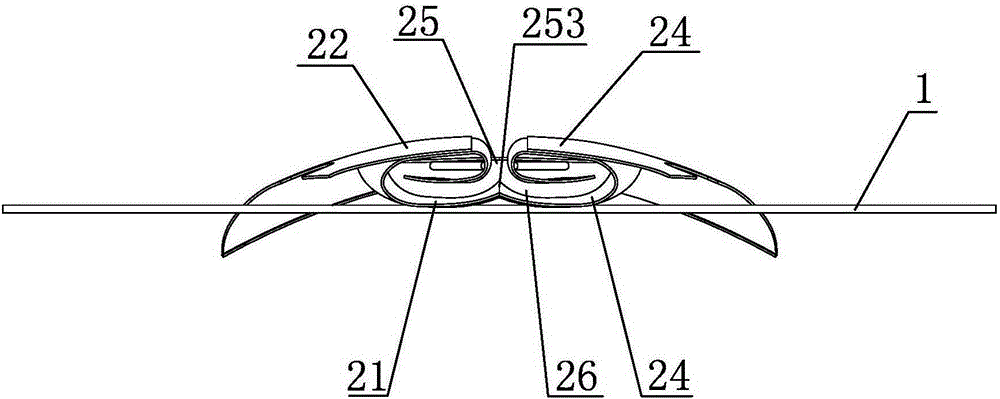

[0027] refer to Figure 1 to Figure 3 As shown, a patchwork halter includes a bottom plate 1, a patchwork seaming device 2, a cloth roll channel adjustment device 3 and a support plate 4;

[0028] The bottom plate 1 is used to fix the patchwork and sewing device 2, and the bottom plate 1 is provided with strip-shaped hole installation holes 11 arranged perpendicularly to the arrangement direction of the middle channel.

[0029] The patchwork seaming device 2 includes a left crimping groove 21, a left pressing plate 22, a right crimping groove 23, a right pressing plate 24, a middle channel 25 and a cloth rolling channel 26;

[0030] The left curling groove 21 is arranged between the left binder plate 22 and the bottom plate 1, the right curling groove 23 is arranged between the right binder plate 24 and the bottom plate 1, and the left curling groove 21 and the right curling groove 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com