Reinforced concrete and preparation method thereof

A technology of reinforced concrete and plain concrete, which is applied in the field of building materials, can solve the problems of low compressive strength and poor flexural strength of concrete, and achieve the effects of enhanced deformation capacity, enhanced bearing capacity, and good blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

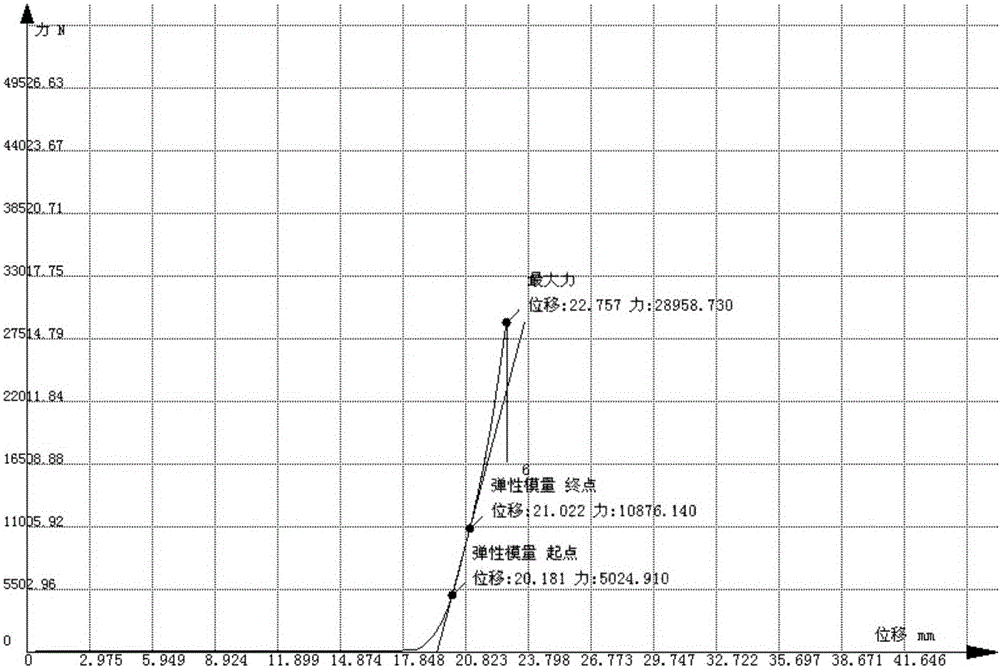

Embodiment 1

[0043] Preparation of reinforced concrete

[0044] 1. Configure reinforced concrete raw materials according to the following weight ratio: 0.2576kg of carbon fiber, 0.1104kg of epoxy resin, 12.00kg of cement, 1.75kg of fly ash, 1.1088kg of mineral powder, 4.93kg of water, 22.40kg of sand, and 31.4kg of stone , wherein carbon fiber and epoxy resin are made of carbon fiber composite material, and the weight of epoxy resin accounts for 30% of the weight of carbon fiber composite material.

[0045] 2. Preparation method

[0046] (1) Infiltrating carbon fiber in epoxy resin to obtain laminated wet prepreg, the thickness of laminated wet prepreg is 0.2mm;

[0047] (2) Process the above laminated wet prepreg into a rod shape with a diameter of 1 mm, solidify at 50°C for 30 minutes, take it out, and cool it down to room temperature naturally to obtain a rod-shaped carbon fiber composite material;

[0048] (3) Stir the carbon fiber composite material and plain concrete obtained in st...

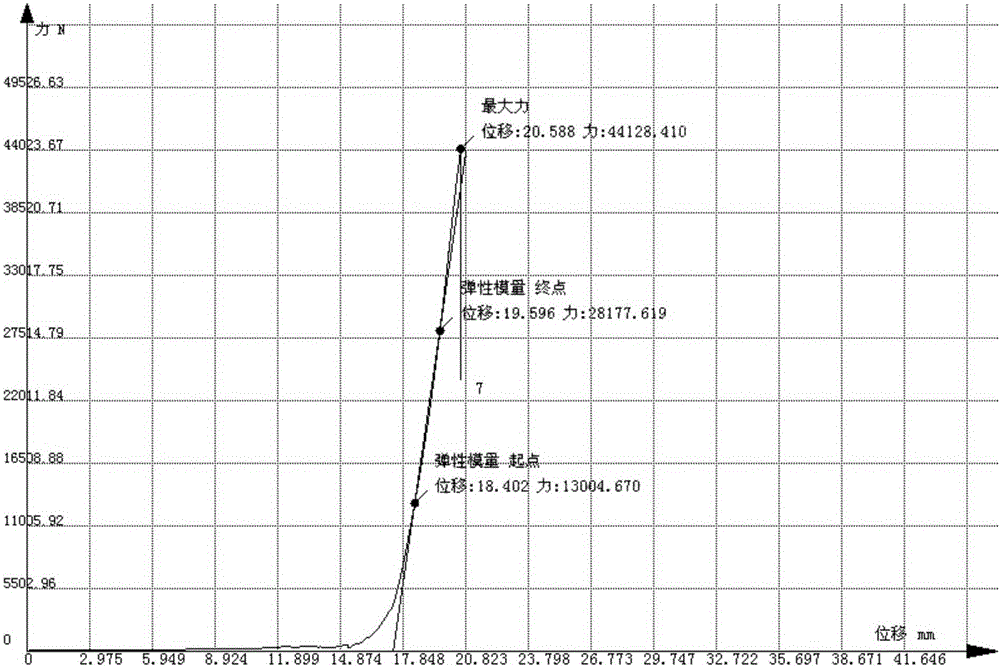

Embodiment 2

[0051] Preparation of reinforced concrete

[0052] 1. Configure reinforced concrete raw materials according to the following weight ratio: 0.56304kg of carbon fiber, 0.25296kg of epoxy resin, 12.66kg of cement, 1.56kg of fly ash, 1.1076kg of mineral powder, 4.95kg of water, 22.38kg of sand, and 31.5kg of stone , wherein carbon fiber and epoxy resin are made of carbon fiber composite material, and the weight of epoxy resin accounts for 31% of the weight of carbon fiber composite material.

[0053] 2. Preparation method

[0054] (1) Infiltrating carbon fiber in epoxy resin to obtain laminated wet prepreg, the thickness of laminated wet prepreg is 1mm;

[0055] (2) Process the above laminated wet prepreg into a narrow sheet with a width of 3mm, solidify at 100°C for 30 minutes, take it out, and cool it naturally to room temperature to obtain a narrow sheet carbon fiber composite material;

[0056] (3) Stir the carbon fiber composite material and the plain concrete obtained in s...

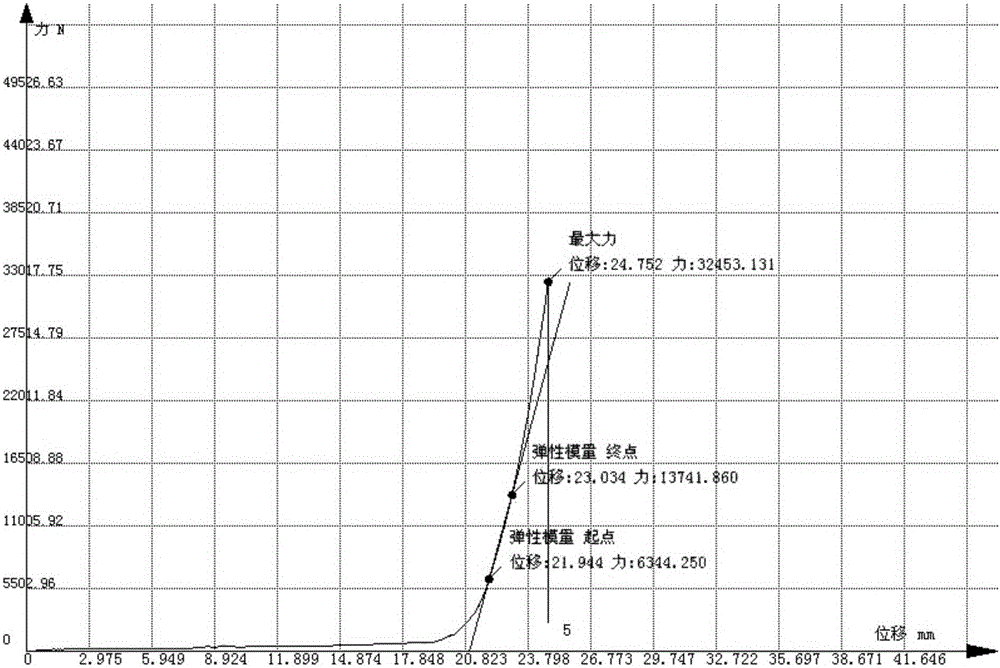

Embodiment 3

[0059] Preparation of reinforced concrete

[0060] 1. Configure reinforced concrete raw materials according to the following weight ratio: 0.83214kg of carbon fiber, 0.40986kg of epoxy resin, 11.98kg of cement, 1.82kg of fly ash, 1.1120kg of mineral powder, 4.88kg of water, 22.35kg of sand, and 30.9kg of stone , wherein carbon fiber and epoxy resin are made into carbon fiber composite material, and the weight of epoxy resin accounts for 33% of the weight of carbon fiber composite material.

[0061] 2. Preparation method

[0062] (1) Infiltrate the carbon fiber in the epoxy resin to obtain a laminated wet prepreg, and the thickness of the laminated wet prepreg is 2mm;

[0063] (2) Process the above laminated wet prepreg into a wide sheet with a width of 10mm, solidify at 150°C for 30 minutes, take it out, and cool it to room temperature naturally to obtain a wide sheet carbon fiber composite material;

[0064] (3) Stir the carbon fiber composite material and plain concrete ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com