High temperature resistant polyester non-woven fabric for lightweight automobile and preparation method thereof

A polyester non-woven fabric and lightweight technology, which is applied in the field of polyester non-woven fabrics for lightweight automobiles and its preparation, can solve the problem of unsatisfactory automobile lightweight and automobile comfort, affecting automobile driving safety, and general noise reduction effect. And other problems, to achieve the effect of protection without discoloration, good sound absorption and sound insulation performance, consistent luster and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

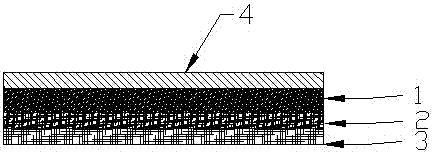

[0031] Embodiment 1: the present invention also relates to the preparation method of the high temperature resistant automobile lightweight polyester non-woven fabric, comprising the following steps:

[0032] 1) preparing a polyester fiber sheet of a polyester fiber sheet layer;

[0033] 2) Sprinkle hot-melt powder between the compact layer 1, semi-compact layer 2 and fluffy layer 3 of the polyester fiber sheet, and firmly bond the three-layer structure through the rolling process;

[0034] 3) Sprinkle hot melt powder on the surface of the compact layer 1;

[0035] 4) Heat the aluminum foil of the aluminum foil layer 4 to 180°C and cover it on the surface of the compact layer;

[0036] 5) After passing the inspection, the preparation of high-temperature-resistant polyester non-woven fabrics for lightweight automobiles is completed.

[0037] Wherein, the preparation method of the polyester fiber sheet of polyester fiber sheet layer comprises:

[0038] 1) Prepare flame-retarda...

Embodiment 2

[0043] Embodiment 2: the present invention also relates to the preparation method of the high temperature resistant automobile lightweight polyester non-woven fabric, comprising the following steps:

[0044] 1) preparing a polyester fiber sheet of a polyester fiber sheet layer;

[0045] 2) Sprinkle hot-melt powder between the compact layer 1, semi-compact layer 2 and fluffy layer 3 of the polyester fiber sheet, and firmly bond the three-layer structure through the rolling process;

[0046] 3) Sprinkle hot melt powder on the surface of the compact layer 1;

[0047] 4) Heat the aluminum foil of the aluminum foil layer 4 to 200°C and cover it on the surface of the compact layer;

[0048] 5) After passing the inspection, the preparation of high-temperature-resistant polyester non-woven fabrics for lightweight automobiles is completed.

[0049] Wherein, the preparation method of the polyester fiber sheet of polyester fiber sheet layer comprises:

[0050] 1) Prepare flame-retarda...

Embodiment 3

[0055] Embodiment 3: the present invention also relates to the preparation method of the high temperature resistant automobile lightweight polyester non-woven fabric, comprising the following steps:

[0056] 1) preparing a polyester fiber sheet of a polyester fiber sheet layer;

[0057] 2) Sprinkle hot-melt powder between the compact layer 1, semi-compact layer 2 and fluffy layer 3 of the polyester fiber sheet, and firmly bond the three-layer structure through the rolling process;

[0058] 3) Sprinkle hot melt powder on the surface of the compact layer 1;

[0059] 4) Heat the aluminum foil of the aluminum foil layer 4 to 230°C and cover it on the surface of the compact layer;

[0060] 5) After passing the inspection, the preparation of high-temperature-resistant polyester non-woven fabrics for lightweight automobiles is completed.

[0061] Wherein, the preparation method of the polyester fiber sheet of polyester fiber sheet layer comprises:

[0062] 1) Prepare flame-retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com