Cooling device for production of plastic medical bottles

A technology for cooling devices and plastic bottles, applied in the field of cooling devices, can solve problems such as easy local deformation and inability to ensure the sealing degree of the bottle mouth and cap, and achieve the effects of improving cooling efficiency, reducing scrap rate, and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

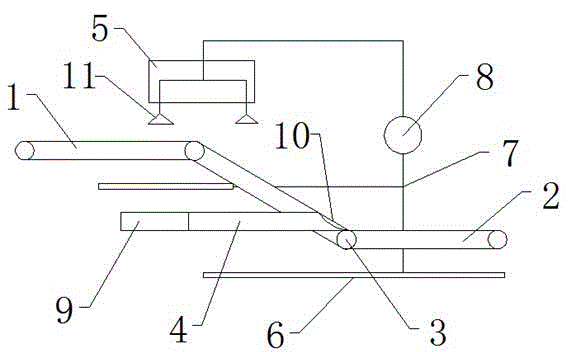

[0014] Such as figure 1 A cooling device for the production of medicinal plastic bottles is shown, including a conveyor belt 1 and a conveyor belt 2 2, the conveyor belt 1 and the conveyor belt 2 are connected by a rotating machine 3, and a cold air is provided on the left side of the conveyor belt 2 The machine device 4 is provided with a water mist cooling device 5 above the conveyor belt 1, and a water receiving device 6 is provided below the conveyor belt 1 and the conveyor belt 2, and the water mist cooling device 5 and the water receiving device 6 are connected through a water pipe 7 , the water pipe 7 is provided with a water pump device 8, and the left side of the air cooler device 4 is provided with a console 9 connected to each device control, the air cooler device 4 includes an outlet 10, and the outlet 10 is flush with the surface of the conveyor belt 2, so The water mist cooling device 5 includes a spray head 11 .

[0015] Wherein, the first conveyor belt 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com