Two-degree-of-freedom workpiece clamping mechanism

A technology of degrees of freedom and workpieces, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve problems such as change uncertainty and difficulty in identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

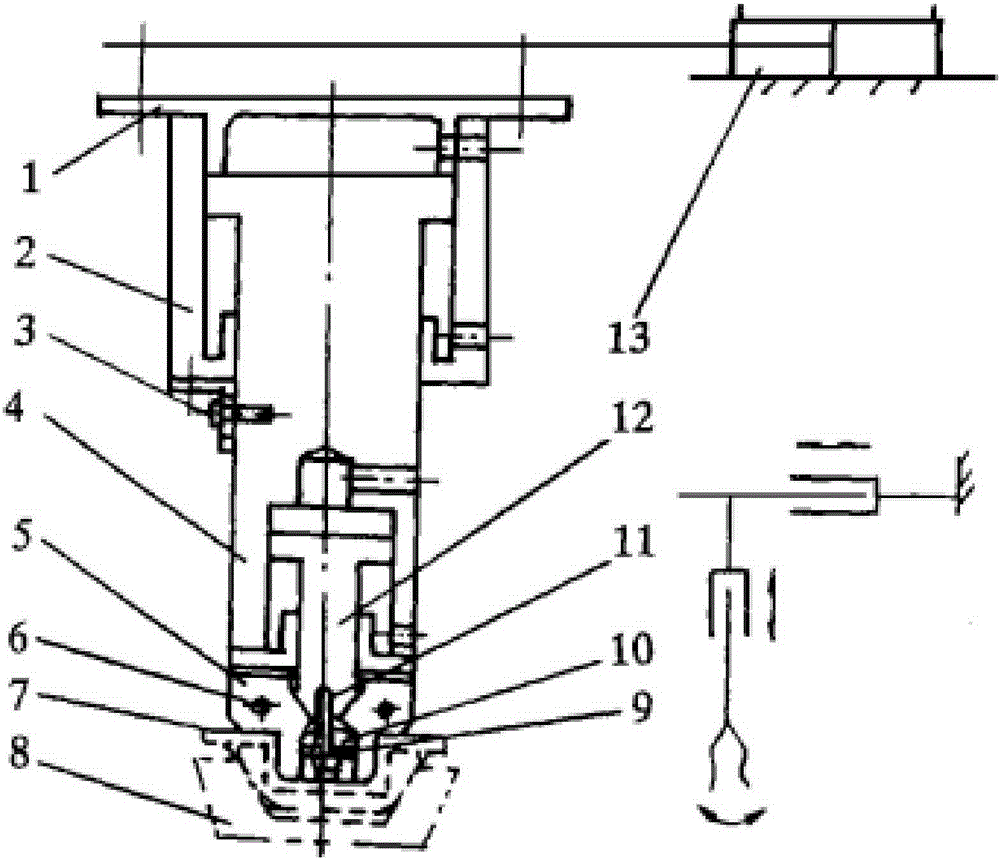

[0018] attached by figure 1As shown, the telescopic pneumatic cylinder 2 is connected to the beam through the bolt 1, the pneumatic cylinder 4 is also the piston rod of the telescopic pneumatic cylinder 2, and the L-shaped plate 3 is fixed on the pneumatic cylinder 4 by bolts to limit the stroke of the pneumatic cylinder 4. When the pneumatic cylinder 4 rose to the highest position, the L-shaped plate leaned against the telescopic pneumatic cylinder 2. The clamping claw 5 is connected to the frame through a cylindrical pin 6. Note that the contact surface between the clamping claw 5 and the air pressure piston rod 12 is designed as an inclined surface. When the air pressure piston rod 12 is extended, the two clamping claws are opened to clamp Item 7. The beam on the telescopic pneumatic cylinder 2 links to each other with the piston column of the hydraulic telescopic cylinder 13, and the left-right direction stroke of the hydraulic telescopic cylinder 13 controls the mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com