Dry powder feeding device

A feeding device and dry powder technology, applied in the field of building materials, can solve the problems of uneven mixing, inability to remove metal impurities, inability to mix dry powder materials evenly, etc., and achieve the effect of facilitating popularization and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

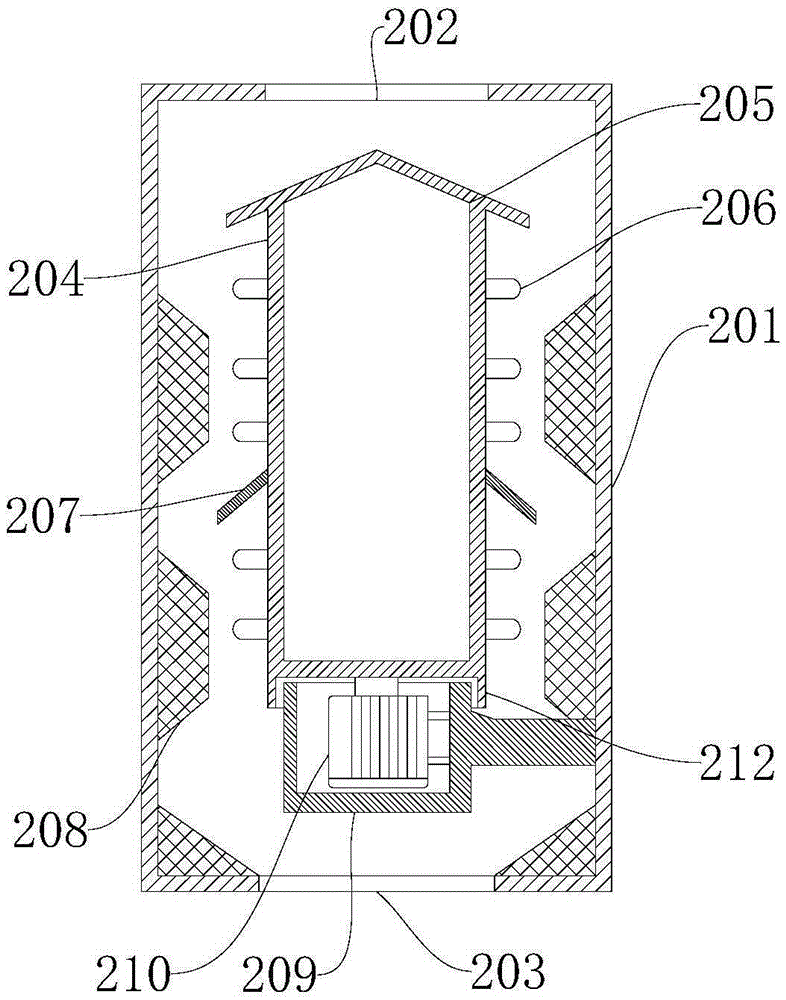

[0043] Such as Figure 1 to Figure 2 As shown, the present embodiment provides a dry powder feeding device, including a housing 201, a stirring roller 204, a magnetic member and a motor fixing seat 209, and the upper and lower ends of the housing 201 are respectively provided with a feed port 202 and a discharge port. The port 203 and the shell 201 are made of metal material, and the whole shell 201 is cylindrical. The feed port 202 and the discharge port 203 are respectively arranged in the middle of the upper and lower ends of the shell 201 .

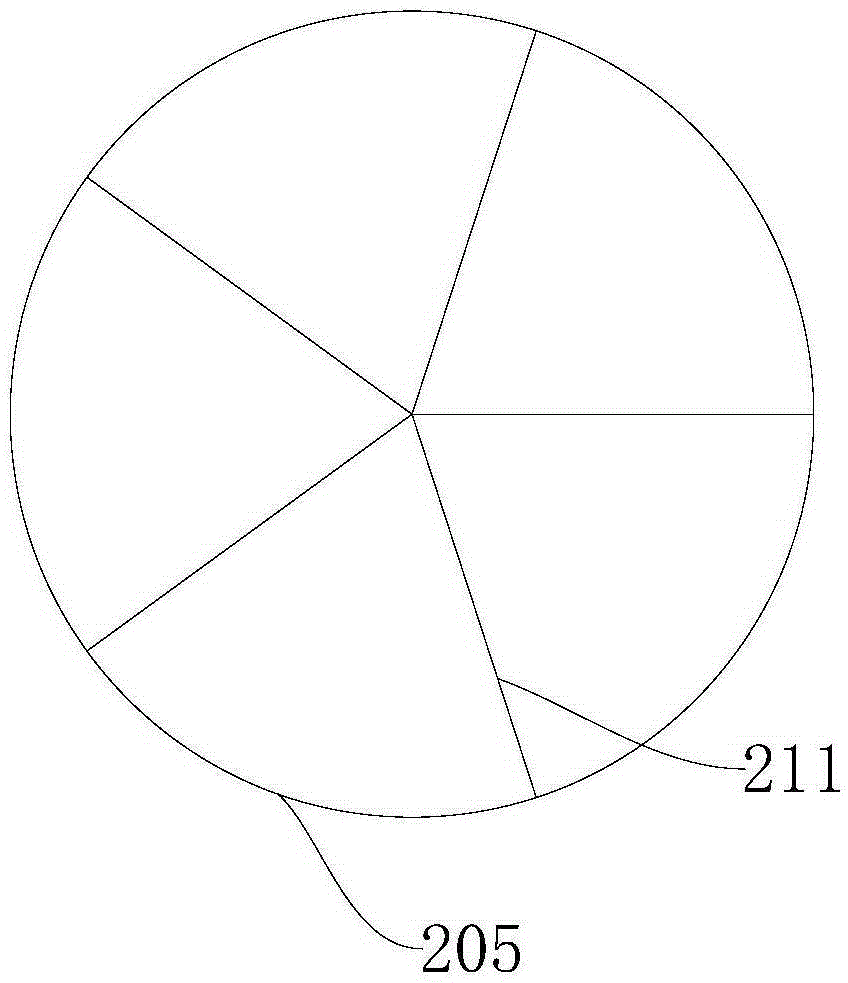

[0044] The stirring roller 204 is vertically arranged in the middle of the housing 201 and is located in the housing 201. The upper end of the stirring roller 204 is provided with a conical cap 205, and the conical cap 205 and the stirring roller 204 are integrally formed. Yes, the brim of the conical cap 205 protrudes from the outer wall of the stirring roller 204 to form a bamboo hat, and the conical cap 205 covers the stirring roll...

Embodiment 2

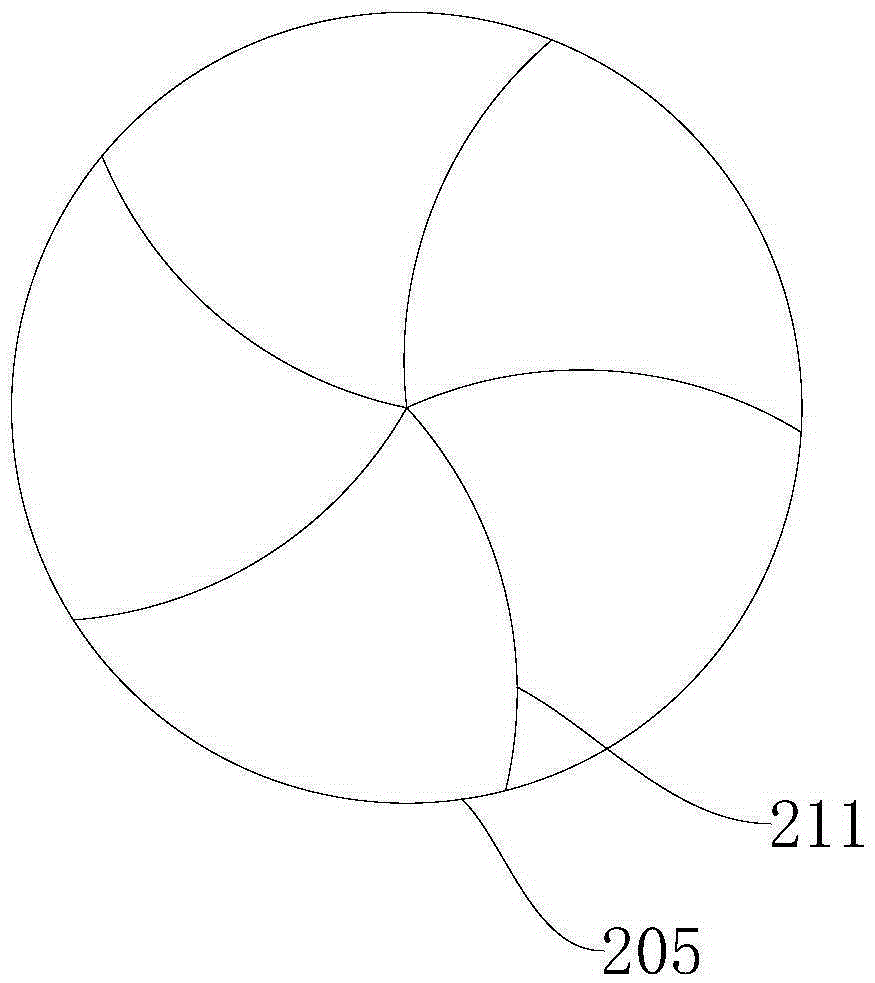

[0061] Embodiment 2, refer to image 3

[0062] The basic structure, principle and technical effect of the dry powder feeding device provided in this example are the same as those in Example 1. For a brief description, for parts not mentioned in this example, refer to the corresponding content in Example 1.

[0063] The difference between this embodiment and Embodiment 1 is that, in this embodiment, the rib 211 on the conical cap 205 is arc-shaped, such as image 3 As shown, there are five ribs 211, and the ribs 211 are drawn from the apex of the conical cap 205 to the brim of the conical cap 205. The advantage of this arc-shaped rib 211 is that the length of the rib 211 is longer than that of a straight line. The convex rib 211 is longer, and the contact area between the conical cap 205 and the dry powder is larger during the rotation process of the conical cap 205, and the pulverizing and mixing effect on the dry powder is better.

[0064] The dry powder feeding device pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com