Magnetic nanometer composite photocatalysis material, and preparation method thereof

A composite photocatalytic and magnetic nanotechnology, applied in the field of g-C3N4/Ag/Fe3O4 nanocomposite photocatalytic materials and their preparation, can solve the problem of poor recyclability and reusability of catalysts, limiting the wide application of photocatalytic materials, and catalytic materials. Loss and other problems, to achieve the effects of adjustable and controllable photocatalytic activity and magnetic size, high visible light photocatalytic activity, and low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

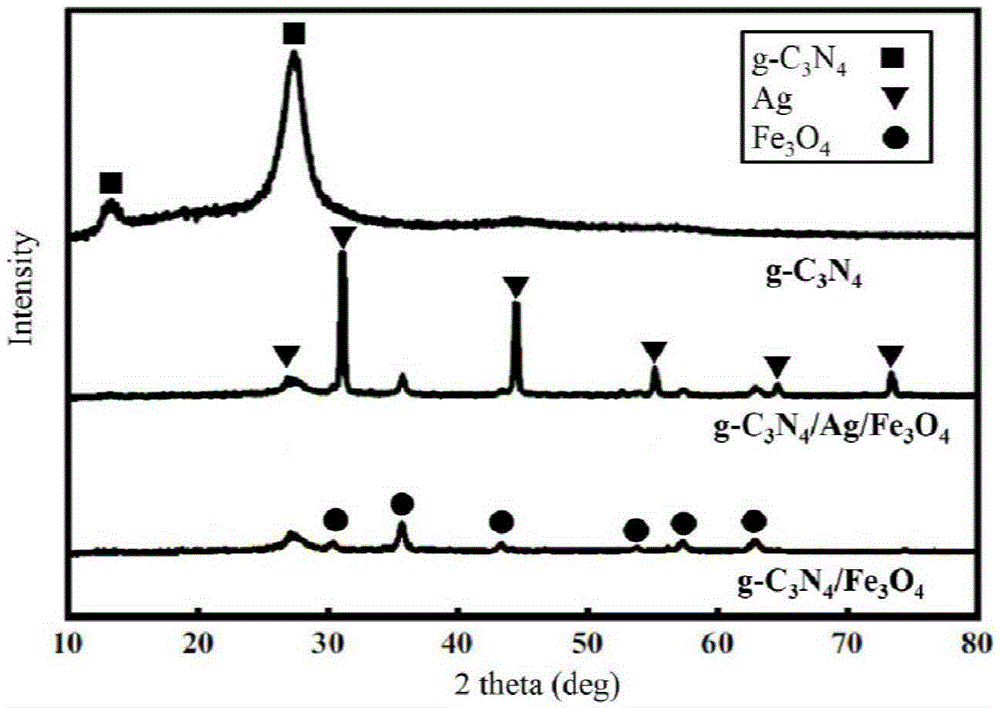

[0033] (1) Weigh 3g of melamine into the crucible, put the crucible into the muffle furnace, heat the muffle furnace to 530°C at a heating rate of 2.3°C / min, keep the temperature and roast for 4h, and take out the crucible after cooling naturally , to obtain light yellow powder g-C 3 N 4 . combine figure 1 Medium g-C 3 N 4 It can be seen from the TEM image that pure g-C 3 N 4 The structure is thin nanosheet.

[0034] (2) Take 125mg of g-C obtained in step (1) 3 N 4 , dissolved in a mixture of 500ml ethanol and water (167ml ethanol, 333ml water), and ultrasonically dispersed for 5h.

[0035] (3) Take an appropriate amount of 1.838gFeCl 3 ·6H 2 O and 0.703g FeCl 2 4H 2 Dissolve O in 20ml distilled water to form a solution, and add g-C 3 N 4 In suspension, the mixture was stirred at 80 °C for 40 min to obtain a red suspension.

[0036] (4) Quickly add appropriate amount of NH 4 OH solution, control the pH value to 10, keep the temperature constant and continue to...

Embodiment 2

[0041] (1) Weigh 3g of melamine into the crucible, put the crucible into the muffle furnace, heat the muffle furnace to 520°C at a heating rate of 2°C / min, keep the temperature and roast for 4.5h, and wait for the crucible to cool naturally Take it out to get light yellow powder g-C 3 N 4 .

[0042] (2) Take 125mg of g-C obtained in step (1) 3 N 4 , dissolved in a mixture of 500ml ethanol and water (167ml ethanol, 333ml water), and ultrasonically dispersed for 4h.

[0043] (3) Take an appropriate amount of 1.838gFeCl 3 ·6H 2 O and 0.703g FeCl 2 4H 2 Dissolve O in 20ml distilled water to form a solution, and add g-C 3 N 4 In suspension, the mixture was stirred at 70 °C for 35 min to obtain a red suspension.

[0044] (4) Quickly add appropriate amount of NH 4 OH solution, control the pH value to 10.5, keep the temperature constant and continue to stir for 35min to obtain a black precipitate.

[0045] (5) After the product is cooled, filter it, wash it repeatedly with...

Embodiment 3

[0049] (1) Weigh 3g of melamine into the crucible, put the crucible into the muffle furnace, heat the muffle furnace to 550°C at a heating rate of 3°C / min, keep the temperature and roast for 5h, and take out the crucible after cooling naturally , to obtain light yellow powder g-C 3 N 4 .

[0050] (2) Take 125mg of g-C obtained in step (1) 3 N 4 , dissolved in a mixture of 500ml ethanol and water (167ml ethanol, 333ml water), and ultrasonically dispersed for 6h.

[0051] (3) Take an appropriate amount of 1.838gFeCl 3 ·6H 2 O and 0.703g FeCl 2 4H 2 Dissolve O in 20ml distilled water to form a solution, and add g-C 3 N 4 In suspension, the mixture was stirred at 90 °C for 30 min to obtain a red suspension.

[0052] (4) Quickly add appropriate amount of NH 4 OH solution, control the pH value to 9.5, keep the temperature constant and continue to stir for 30min to obtain a black precipitate.

[0053] (5) After the product is cooled, filter it, wash it repeatedly with dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com