Automatic cutting device for plaster

An automatic cutting device and gypsum technology, applied in the field of medical appliances, can solve problems such as low working efficiency of gypsum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

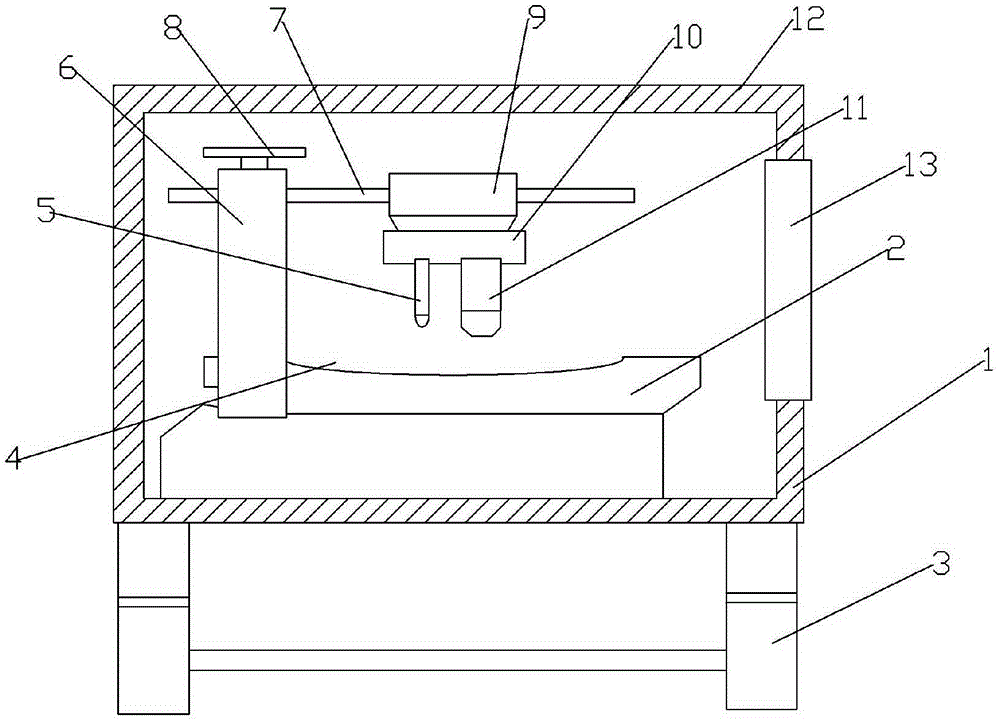

[0011] The reference signs in the drawings of the description include: frame 1, workbench 2, support frame 3, groove 4, infrared detector 5, support 6, strut 7, adjusting bolt 8, slider 9, telescopic cylinder 10 , Plaster saw 11, shell 12, entrance 13.

[0012] The embodiment is basically as attached figure 1 Shown: an automatic cutting device for gypsum, including a frame 1 and a workbench 2 for placing gypsum on the frame 1, a support frame 3 is provided at the bottom of the frame 1, and the support frame 3 passes through the four corners of the frame 1 Composed of four telescopic rods, the middle part of the workbench 2 is provided with a groove 4 matching the size of the gypsum, and an infrared detector 5 is arranged above the workbench 2, and the infrared detector 5 is fixed above the workbench 2 through a support 6 , a horizontal strut 7 is installed on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com