Fastened type spliced sealing structure for solar photovoltaic components

A solar photovoltaic and sealing structure technology, applied in the field of solar energy, can solve problems such as poor sealing, foam falling, waste of waterproof glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

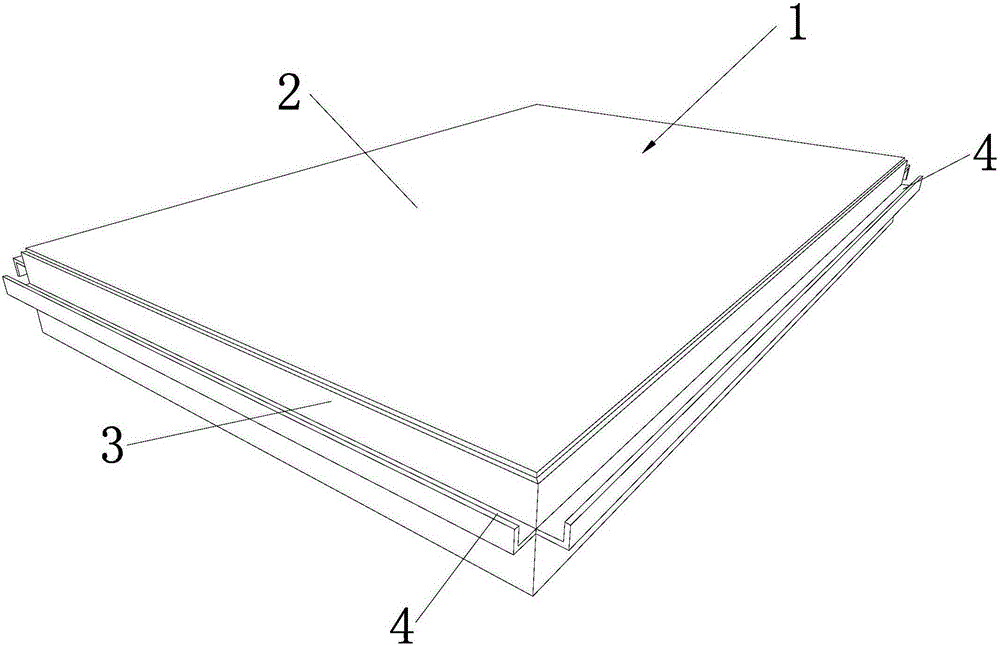

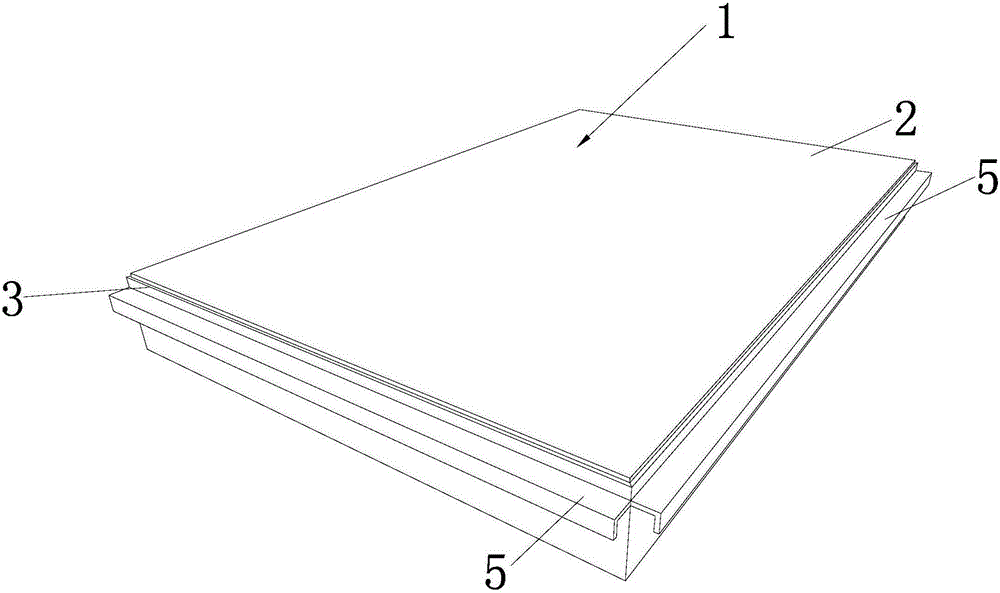

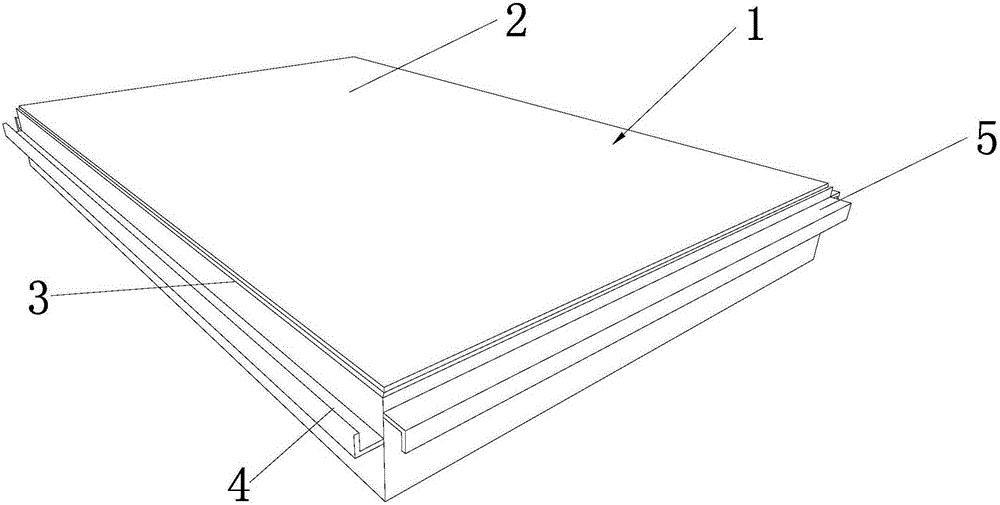

[0015] A solar photovoltaic module snap-on splicing sealing structure, such as Figures 1 to 5 As shown, it is composed of several solar photovoltaic modules 1 spliced together, each of the solar photovoltaic modules 1 includes a square solar panel assembly 2 and four frame profiles 3 arranged on the four sides of the solar panel assembly 2. The outer walls of the four frame profiles 3 are provided with an upper lap groove 4 with an upward opening or a lower lap groove 5 with an opening downward. In order to avoid the influence of thermal expansion and contraction, the adjacent solar photovoltaic modules 1 The upper and lower lap grooves 4 and 5 are fastened together without contact with sufficient clearance in the horizontal direction (that is, there are gaps A and B between the horizontal and longitudinal directions of the upper and lower lap grooves), and There should also be enough gap C in the horizontal direction between the outer vertical edge of the frame profile and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com