Voltage-regulating variable-frequency hierarchical control ultrasonic plastic welding power supply

A technology of plastic welding and hierarchical control, applied in the direction of adjusting electrical variables, control/regulating systems, electrical components, etc., can solve the problems of unfavorable power output, no anti-resonance point, large load impedance angle, etc., to achieve voltage regulation Or the effect of speeding up the power regulation response, reducing the current ripple, and widening the voltage regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

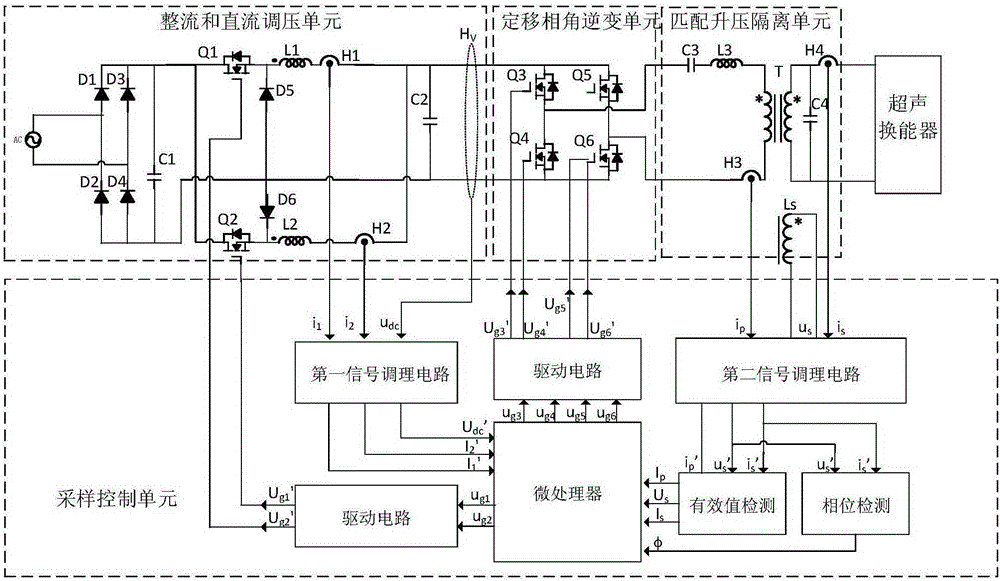

[0023] Such as figure 1 As shown, an ultrasonic plastic welding power supply with voltage regulation, frequency conversion and graded control includes five units: sampling control unit, rectification and DC voltage regulation unit, fixed phase angle inverter unit, matching boost isolation unit and ultrasonic transducer ; Wherein, the sampling control unit includes: a microprocessor, a first signal conditioning circuit, a second signal conditioning circuit, a drive circuit, an effective value detection circuit and a phase detection circuit; wherein, the first signal conditioning circuit and the microprocessor's The AD sampling port is connected; the driving circuit is connected with the EPWM port of the microprocessor; the primary side current conditioning signal output te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com