Ship loading performance optimization system

A ship and performance technology, applied in the field of ship loading performance optimization system, can solve the problems of hull structure damage, rib de-welding, steel plate cracking, etc., and achieve the effects of reasonable draft, reducing emissions and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0105] As a ship professional software for nautical personnel, the ship loading calculation system should be as perfect as possible in terms of functions and as accurate as possible in data, and the interface should be as simple and friendly as possible, easy to operate, and have good fault tolerance. The specific implementation is as follows:

[0106] 1. Enter the main menu and sub-calculation system of the ship loading calculation system.

[0107] 2. Input the cargo, oil, water and other loading information of the ship into the ship loading performance optimization system.

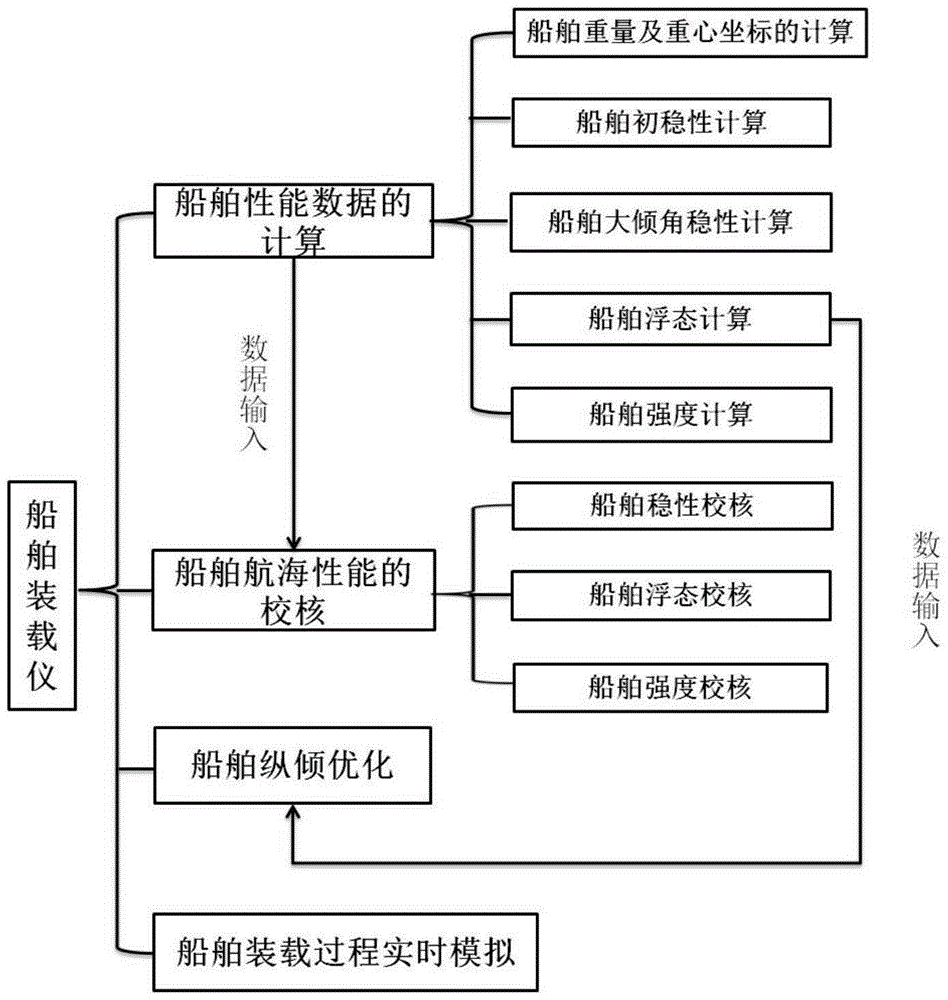

[0108] 3. According to the calculation data of the ship loading performance optimization system required by the user, different sub-calculation systems are selected, including the calculation of ship performance data, the check of ship navigation performance, the optimization calculation of ship trim and the optimization of ship loading.

[0109] 4. Enter different ship data in the corresponding sub-cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com