Crude oil and tar water content measuring device by Karl Fischer coulometry method

A measuring device, crude oil technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of inaccuracy, cumbersome test process, and many impurities, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

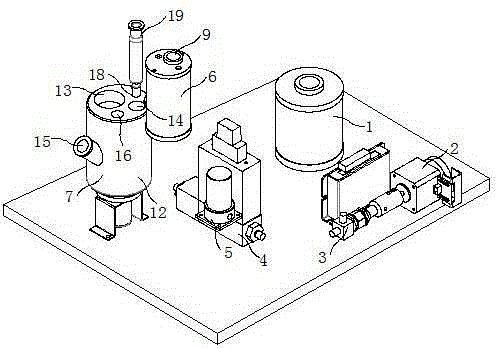

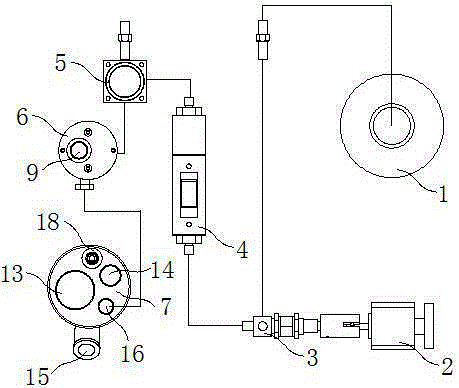

[0014] Below in conjunction with accompanying drawing a kind of Karl Fischer coulometric method crude oil of the present invention, tar water content measuring device, be further described:

[0015] A kind of Karl Fischer coulomb method crude oil of the present invention, tar water content measuring device is made up of nitrogen storage tank 1, stepper motor 2, needle valve 3, mass flowmeter 4, electromagnetic valve 5, metal bath gasification unit 6, The card type coulomb method electrolytic cell 7 and the control unit 8 constitute.

[0016] Wherein, the valve stem of the needle valve 3 is connected to the power output shaft of the stepping motor 2 , and the control unit 8 controls the gas flow of the needle valve 3 by controlling the stepping motor 2 .

[0017] In this device, the nitrogen storage tank 1, the needle valve 3, the mass flow meter 4, the solenoid valve 5, the metal bath gasification unit 6 and the Cassette Coulomb method electrolytic cell 7 are sequentially conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com