Method for measuring oil content and water content in drilling fluid through low-field nuclear magnetic resonance

A technology of low-field nuclear magnetic resonance and drilling fluid, which is applied in the field of simultaneous measurement of oil content and water content of drilling fluid by low-field nuclear magnetic resonance, and the measurement of oil content and water content of water-based drilling fluid. It can solve the problem that drilling fluid has not been reported, etc. problem, to achieve the effect of fast test speed, high measurement accuracy and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Purpose of the test

[0032] Test the effect of manganese chloride on the T2 relaxation time of oil and water, test the relaxation characteristics of drilling fluid and drilling fluid stirred with manganese chloride, and the oil content and water content of drilling fluid.

[0033] 2. Test materials

[0034] Distilled water, manganese chloride, oil, drilling fluid 1#, drilling fluid 2#.

[0035] 3. Test equipment

[0036] PQ001 was produced by Suzhou Newmay Electronic Technology Co., Ltd., the resonance frequency is 23.346MHz, the magnet strength is 0.54T, the probe coil diameter is 25mm, and the experimental temperature is controlled at 31.99~32.01℃.

[0037] 4. Preparation of test samples

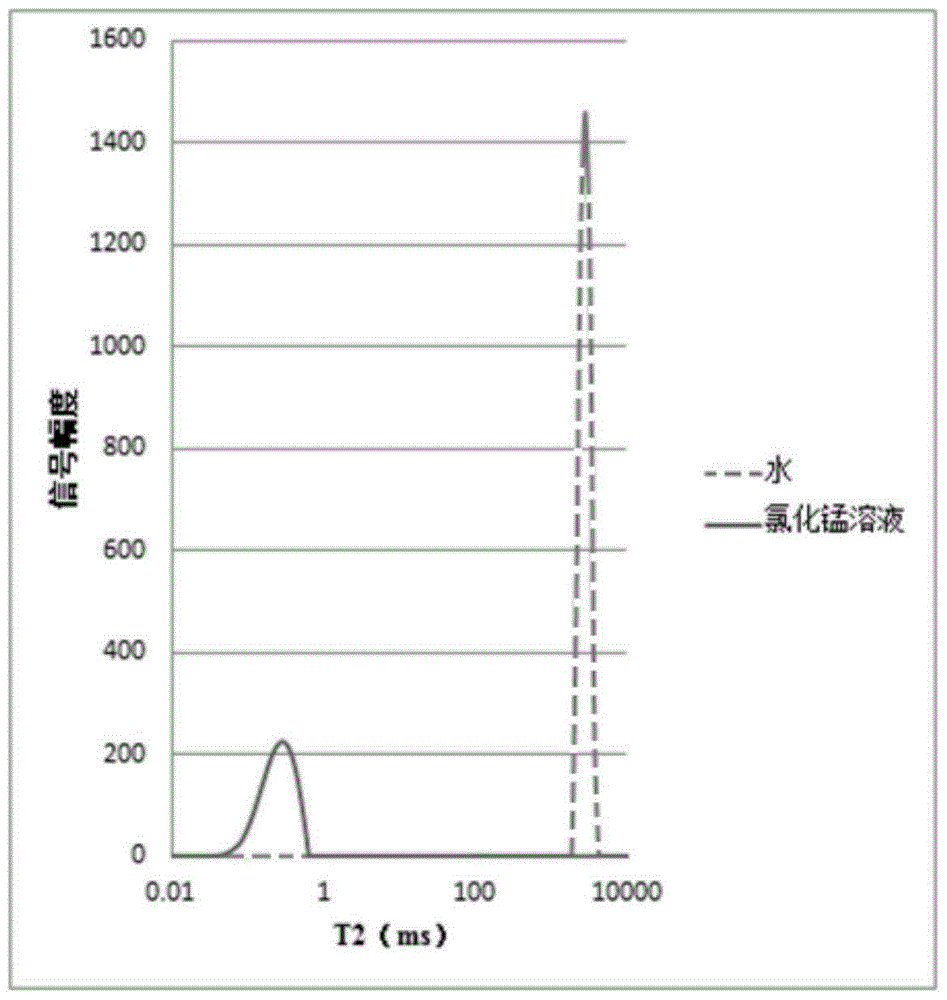

[0038] Weigh 1.5g of water to test its T2 relaxation spectrum, add a small amount of manganese chloride crystals in the water and stir well before testing the T2 relaxation spectrum, refer to figure 1 shown;

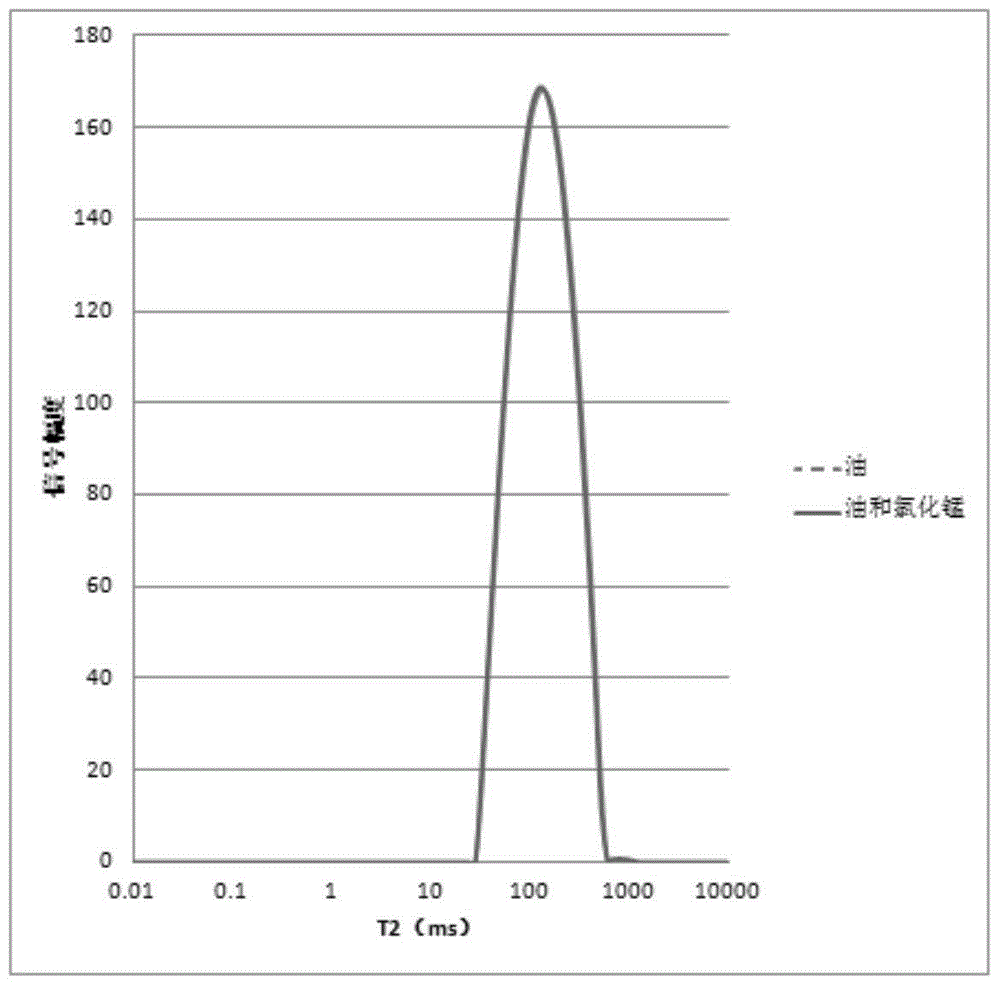

[0039] Weigh 1.5g of oil to test its T2 relaxation spectrum, add...

Embodiment 2

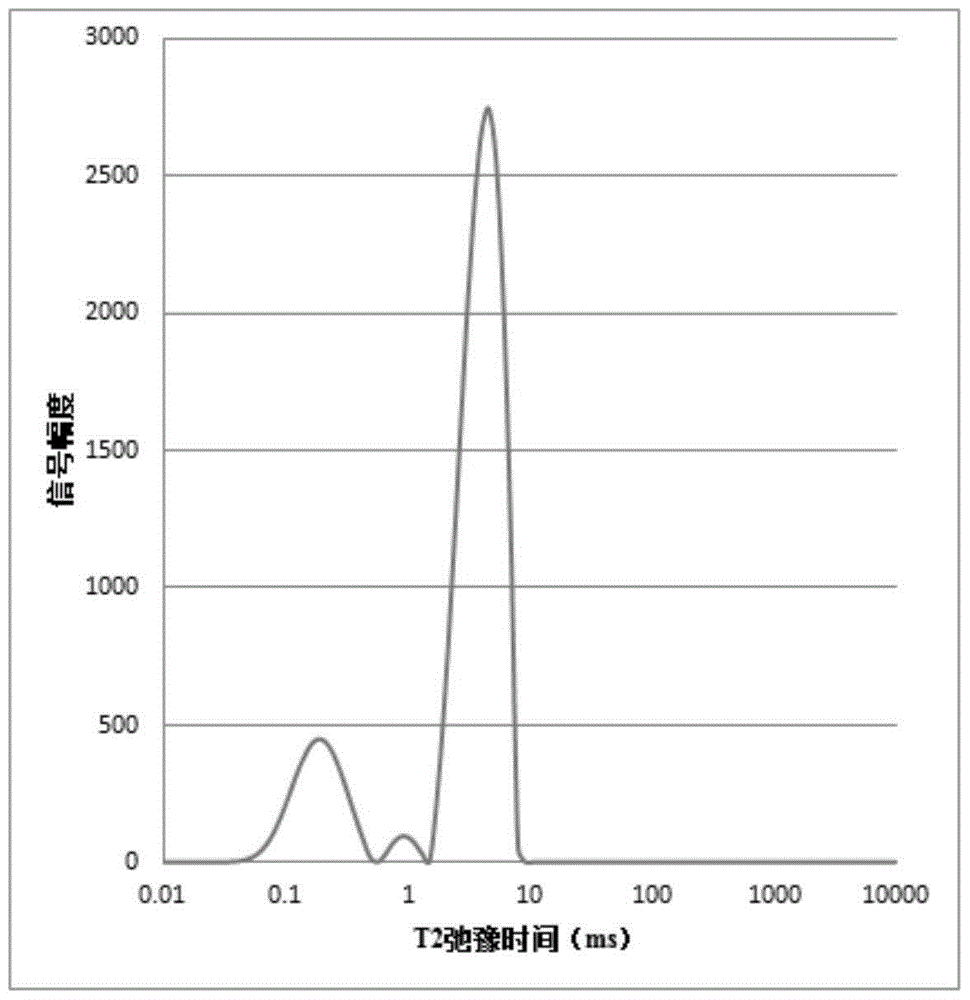

[0055] Drilling fluid 2# oil content and water content test, combined Figure 7 , Figure 8 , Figure 9 and Figure 10 It can be seen that:

[0056] (1) The relaxation time of drilling fluid 2# is between 0.25 and 100ms,

[0057] (2) After adding manganese chloride and stirring evenly, the relaxation time of water in the drilling fluid is suppressed to before 1ms, and the relaxation time and signal of oil are not affected.

[0058] It can be seen from the principle that adding an appropriate amount of manganese chloride in drilling fluid 2# can shorten the relaxation time of water in drilling fluid 2# to within 1ms, and the signal of oil is after 1ms, so oil and water can be distinguished.

[0059] Crude oil peak area in drilling fluid 2# = peak area after 1ms after manganese saturation, water peak area in drilling fluid 2# = peak area before manganese saturation - peak area after 1ms after manganese saturation, crude oil in drilling fluid 2# Put the peak area and water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com