Vacuum pumping device and method for geotechnical test

A technology of vacuum pumping device and geotechnical test, which is applied in the preparation of test samples, etc., can solve the problem of soil samples or sediments easily overflowing the sample container, and achieve the effect of automatic liquid-gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

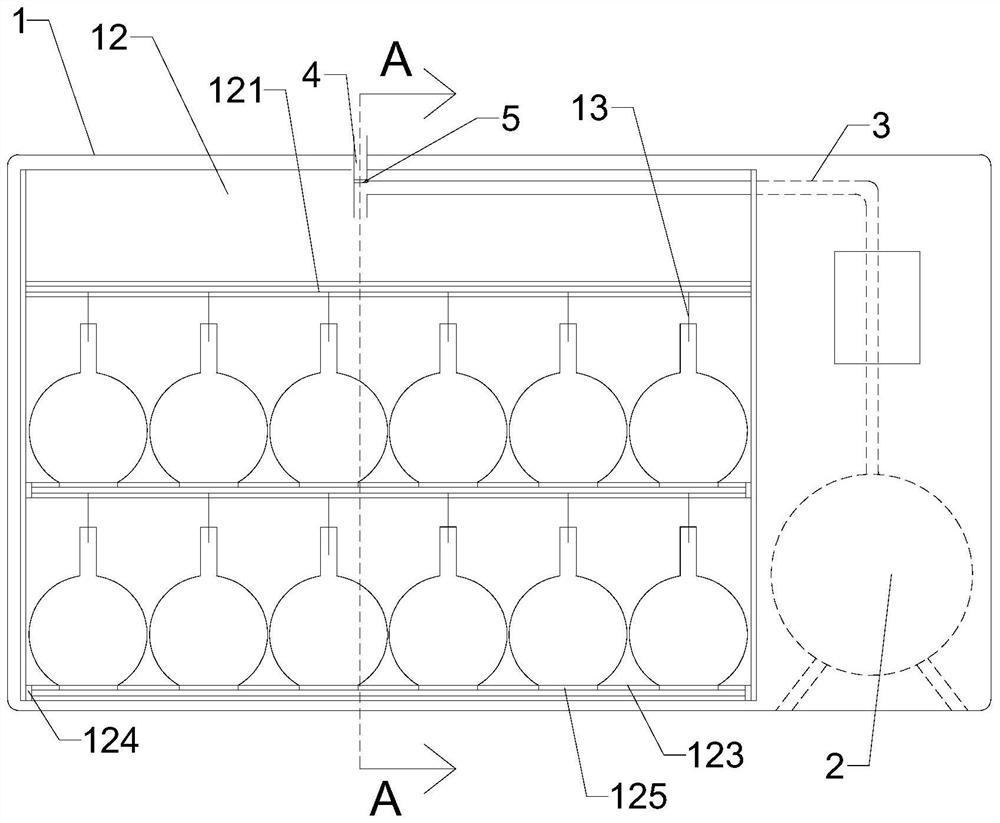

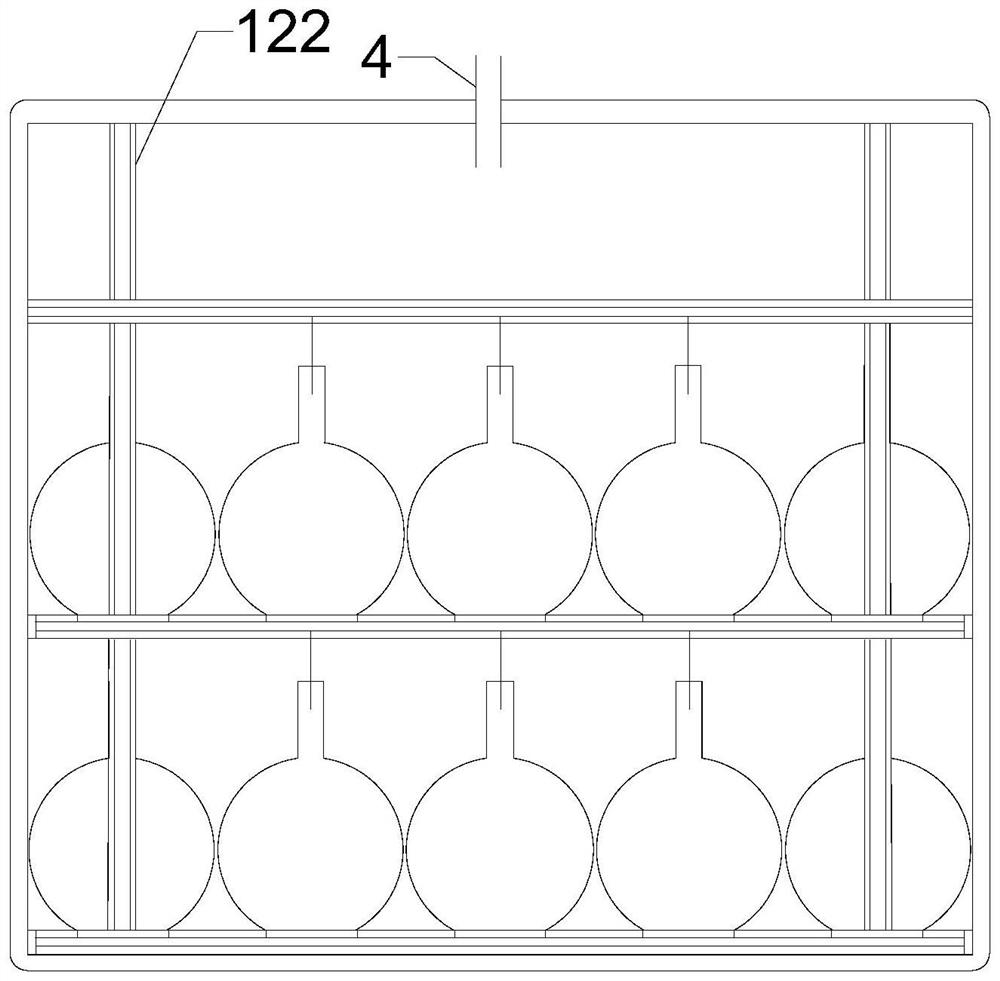

[0036] like Figure 1-4 As shown, a vacuum pumping device for a geotechnical test includes a vacuum box 1 with a vacuum chamber 11 inside, a vacuum pump 2, an exhaust channel 3, an exhaust channel 4, a vacuum valve 5 and a controller, the vacuum box One side of the body 1 is provided with an opening communicating with the vacuum chamber 11 , the opening is covered with a closed door body, and one end of the exhaust passage 3 and one end of the exhaust passage 4 are connected to the vacuum chamber 11 through the vacuum valve 5 , the other end of the suction channel 3 is connected to the vacuum pump 2, the vacuum chamber 11 is provided with a number of detection parts 12 along the height direction, and the detection part is provided with a number of detection units 13, the vacuum pump 2, the detection unit 13 The vacuum valve 5 is connected to the controller; the vacuum valve 5 is used to drive one of the suction channel 3 and the exhaust channel 4 to communicate with the vacuum...

Embodiment 2

[0039] like Figure 1-4 As shown, a vacuum pumping device for a geotechnical test includes a vacuum box 1 with a vacuum chamber 11 inside, a vacuum pump 2, an exhaust channel 3, an exhaust channel 4, a vacuum valve 5 and a controller, the vacuum box One side of the body 1 is provided with an opening communicating with the vacuum chamber 11 , the opening is covered with a closed door body, and one end of the exhaust passage 3 and one end of the exhaust passage 4 are connected to the vacuum chamber 11 through the vacuum valve 5 , the other end of the suction channel 3 is connected to the vacuum pump 2, the vacuum chamber 11 is provided with a number of detection parts 12 along the height direction, and the detection part is provided with a number of detection units 13, the vacuum pump 2, the detection unit 13 The vacuum valve 5 is connected to the controller; the vacuum valve 5 is used to drive one of the suction channel 3 and the exhaust channel 4 to communicate with the vacuum...

Embodiment 3

[0042] like Figure 1-4 As shown, a vacuum pumping method of a geotechnical test, applied to the controller of the vacuum pumping device of the geotechnical test as described in Embodiment 1 or 2, comprises the following steps:

[0043] S1: place the sample container containing the sample in the detection part 12, drive the detection unit 13 to extend into the sample container, and close the closed door;

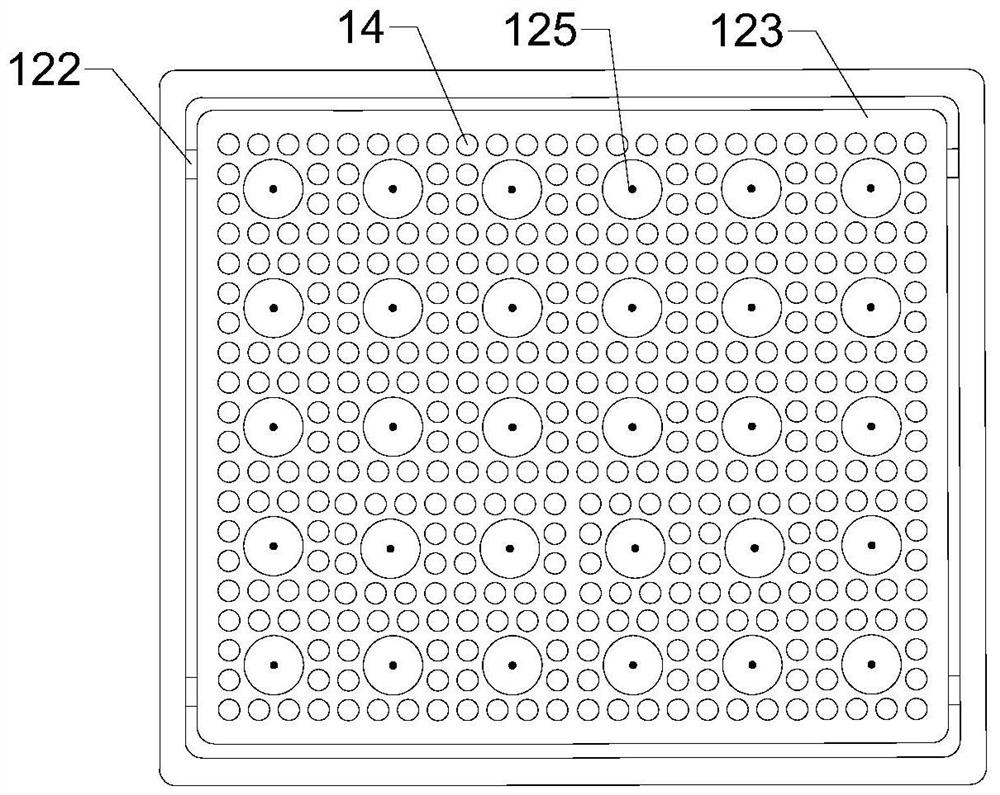

[0044] Specifically, the bottom plate 123 is moved out of the vacuum chamber 11 through the horizontal guide rail 124, so that the tester can place the sample container containing the sample on the bottom plate 123. Preferably, the bottom plate 123 is provided with a positioning groove 125 for fixing the sample container. position and posture, then the horizontal guide rail 124 resets the bottom plate 123, and then the vertical guide rail 122 drives the layer plate 121 to descend, so that the detection end of the detection unit 13 extends into the sample container, preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com