Coating Life Prediction Method Based on Evolution Mechanism of Stress and Cohesion Strength

A technology that combines strength and coating life, applied in measuring devices, special data processing applications, instruments, etc., can solve problems such as no coating life prediction method, and achieve comprehensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] A coating life prediction method based on stress and bonding strength evolution mechanism, including the following steps:

[0030] Step 1. Establish the residual stress-time variation relationship and the oxide layer stress-time variation relationship; according to the time variation relationship, the residual stress-time variation relationship and the oxide layer stress-time variation relationship are superimposed according to time to obtain the coating internal stress- Time-varying relationship, that is, the physical model of coating stress evolution;

[0031] Step 2. Thermal cycle accelerated sample aging:

[0032] Prepare a large number of coated samples, put the coated samples into the sample aging equipment and carry out high and low temperature cycle thermal aging treatment with different time lengths, so as to accelerate the aging speed of the samples, and obtain artificially accelerated aging samples i=( 1,2,3,...,N);

[0033] Step 3, XRD diffraction and data...

specific Embodiment approach 2

[0041] The specific operation steps for obtaining the physical model of coating stress evolution in step 1 of this embodiment are as follows:

[0042] Step 1. Collect the temperature-time function relationship of the coating service or storage environment, and use the lowest temperature as the reference temperature to obtain the reference temperature-time function relationship;

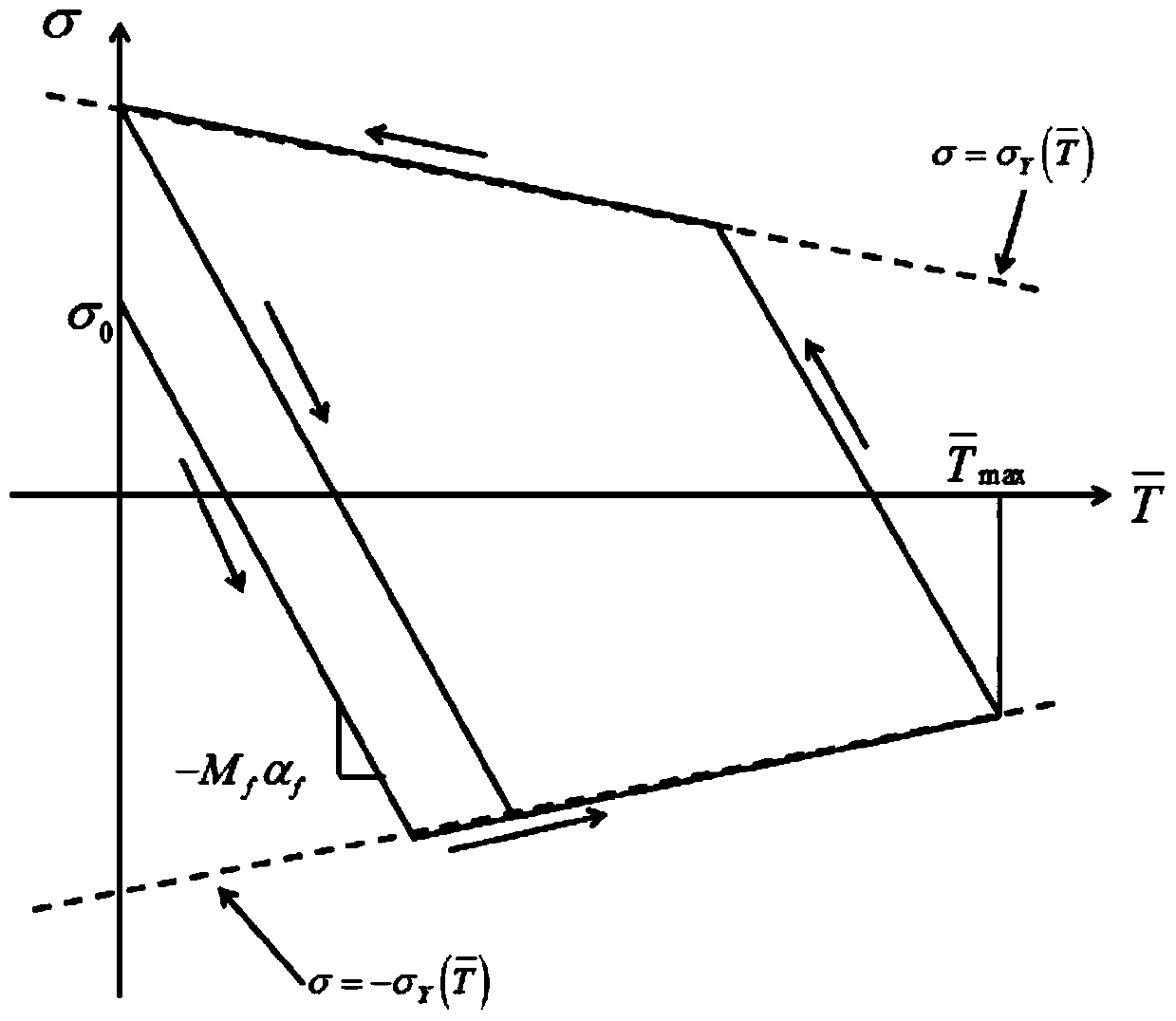

[0043] Step 2. Establish the residual stress-time change relationship: take 24 hours as a temperature change cycle, simplify the coating system according to the elastic-ideal plastic film model on the thick substrate, and calculate the thermal stress according to the formula Establish the residual stress-temperature cycle change model, and combine the reference temperature-time function relationship to obtain the residual stress-time change relationship;

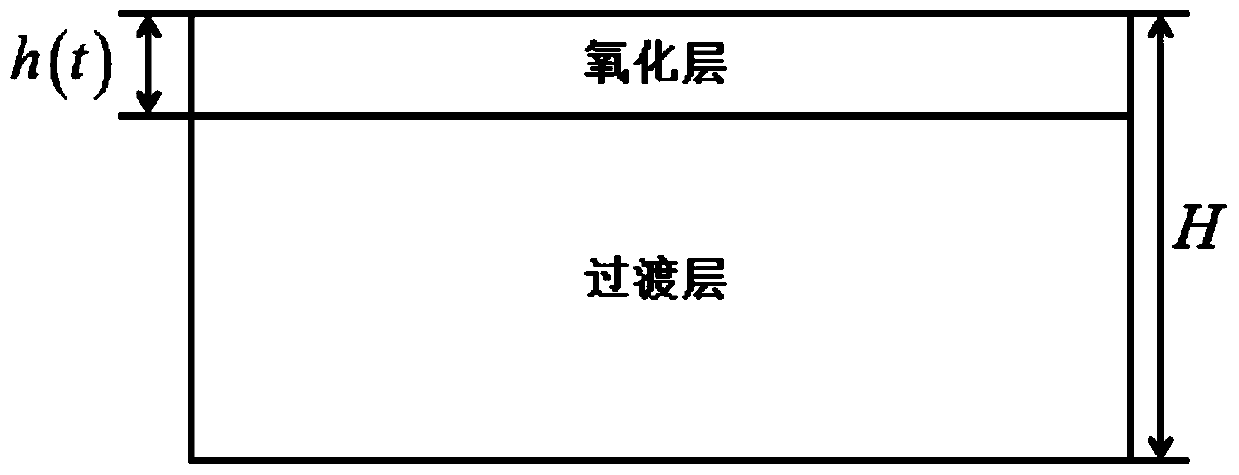

[0044] Step 3, establishing the stress-time variation relationship of the oxide layer: according to the deformation coordination equation (deforma...

specific Embodiment approach 3

[0048] The specific operation steps for obtaining the reference temperature-time function relationship in step 1 of the present embodiment are as follows:

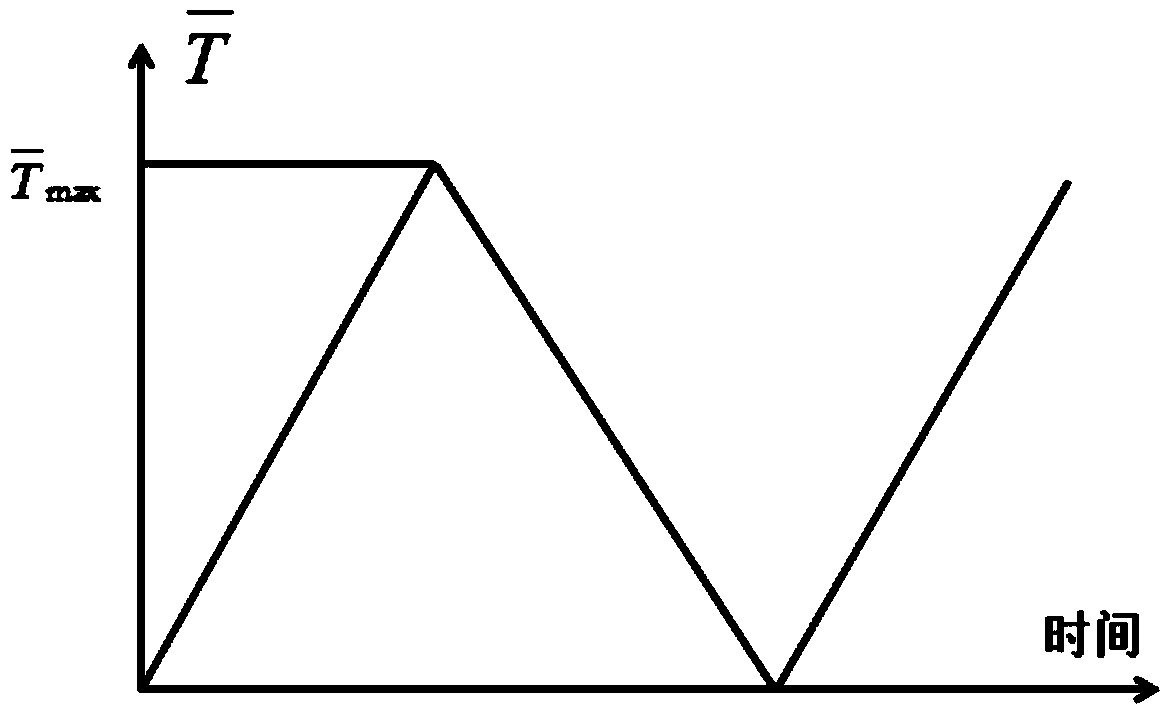

[0049] First put the coating in service or storage environment, record the lowest temperature T in this environment min , and collect the temperature-time function relationship of the coating; the current temperature T is expressed as the reference temperature with the lowest temperature as the reference , the reference temperature Note that the reference temperature corresponding to the highest temperature is

[0050] For a temperature change cycle, the reference temperature first rises from 0 to then drop to 0, then rise to By plotting the reference temperature history against time, the reference temperature-time function relationship described in step 1 can be obtained. It should be noted that since the deformation rate is not sensitive to temperature, the specific "waveform" of the reference temperature-time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com