Rubber tube braiding wire quantification method

A rubber hose and wire technology, applied in the quantitative field of rubber hose braiding thread, can solve the problems of lack of precision production, waste, easy explosion of rubber hose, etc., and achieve the effect of avoiding relative displacement, more operating space, and stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

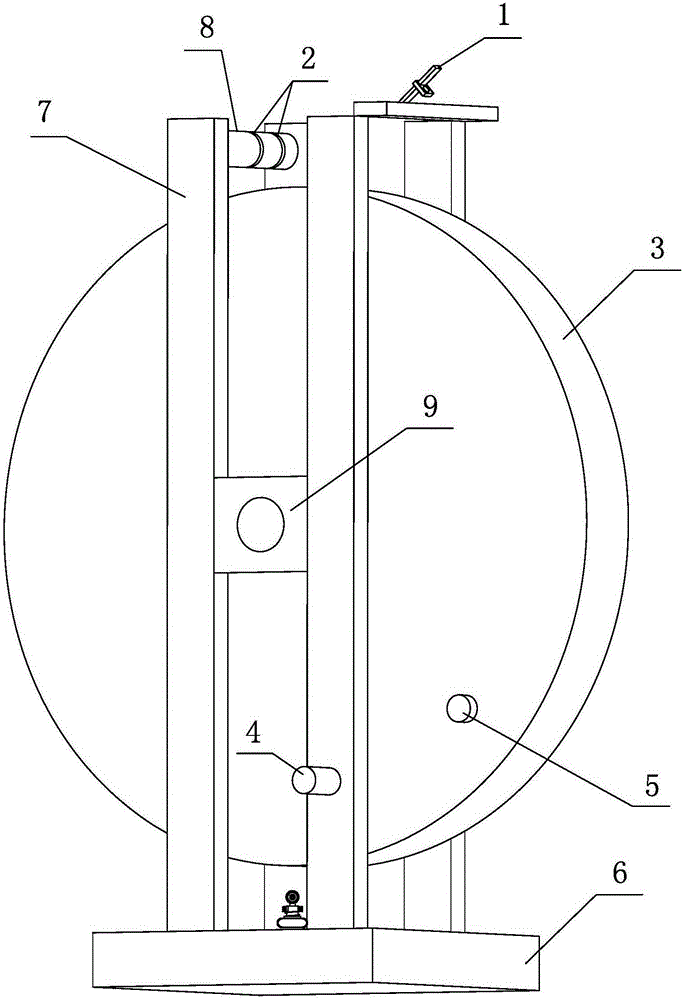

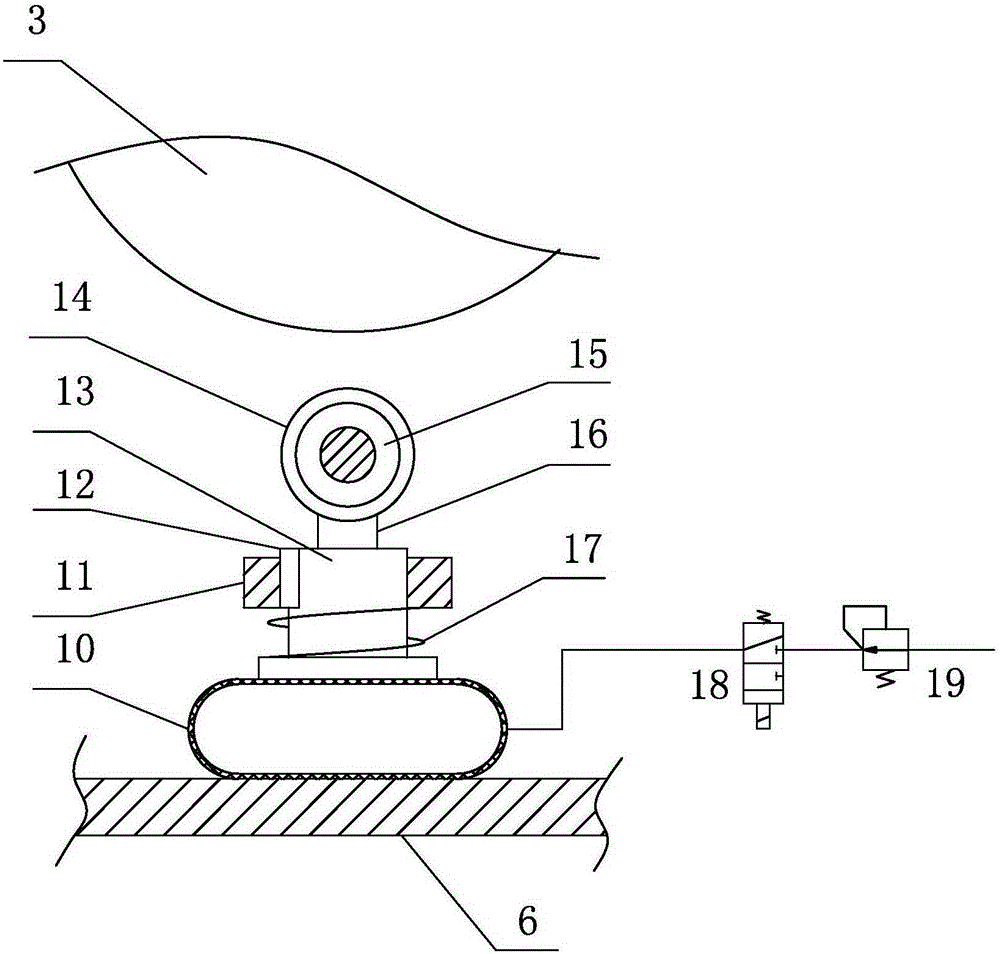

[0016] Embodiment: a kind of quantitative method of rubber hose braiding thread of the present invention, as attached figure 1 As shown, the wire inlet and the wire outlet are set on the outer circumference side of the meter wheel 3; the wire to be wound is wound on the meter wheel 3 through the wire inlet, and then removed from the meter wheel 3 through the wire outlet and wound on the on the spool of the plying machine; the spool rolls, and the wire rotates with the spool and pulls the meter wheel 3 to rotate; the proximity switch 4, the trigger device 5 and the external control system record and calculate the effective number of turns of the meter wheel 3, and the control system according to Record the length of the wire rod wound in a single turn of the rice wheel 3, and calculate the length of the wire rod wound into the spool of the plying machine.

[0017] The meter wheel 3 is rotatably fixedly connected to the frame 6; the frame 6 has a pressing rod 8 and a proximity s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com