Bipitch chain transmission mechanism

A chain drive, double-pitch technology, applied in the direction of transmission chain, transmission device, mechanical equipment, etc., can solve the problems of fast wear, affecting the working reliability and service life of the bucket chain elevator, and easy blockage of the meshing area of the chain teeth. , to achieve the effect of improving reliability, less chain assembly parts, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] figure 1 The middle driving sprocket 3 is located at the driving end, and the driven sprocket 4 is located at the driven end, their axes are parallel, the structures are identical and they are located in the same motion plane. When the driving sprocket 3 rotates clockwise, the contact between the driving sprocket 3 and the chain link 1 is located in the primary meshing area; and the contact between the driven sprocket 4 and the chain link 1 is located in the secondary meshing area. When the driving sprocket 3 rotates counterclockwise, there will be a certain relative sliding between the teeth of the sprocket and the chain link 1, which is convenient for removing the blocking material in the meshing area and preventing the transmission mechanism from being stuck or unable to start.

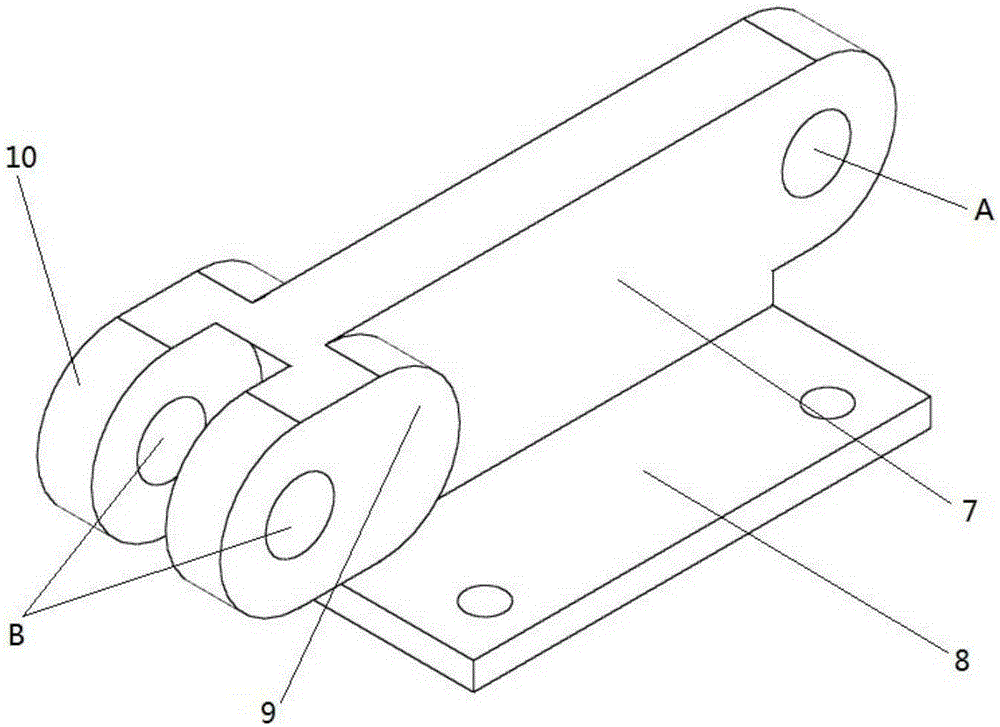

[0023] figure 2 is a schematic diagram of the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com