Superfine fire coal particle control method based on pillared modified montmorillonite

A technology of ultra-fine particles and control methods, which is applied in the direction of fuel, solid fuel, petroleum industry, etc., and can solve problems such as human health and ecological environment hazards, ultra-fine particle emissions, etc., to achieve cheap prices, improved emission reduction effects, and technological processes Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

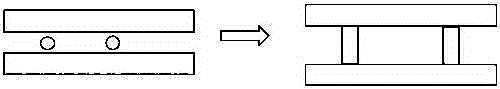

Method used

Image

Examples

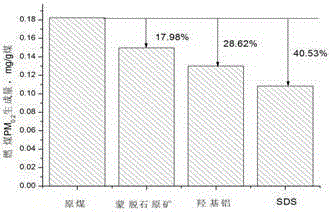

Embodiment 1

[0041] Preparation of hydroxyaluminum modified montmorillonite:

[0042] 1) Hydrolyze the aluminum chloride solution to obtain the hydroxyaluminum pillar solution, add 960mL0.3mol / LNaOH solution dropwise to 300mL0.4mol / LAlCl 3 The solution was mechanically stirred for 2 hours after the dropwise addition was completed. In order to avoid the precipitation of aluminum hydroxide, the dropwise addition process was carried out slowly. Get the OH of the hydroxyaluminum pillar liquid - / A +3 2.4, aged for three days at room temperature;

[0043] 2) Put the montmorillonite in an oven at 45°C for 3 hours to remove the adsorbed water;

[0044] 3) Take 20g of montmorillonite, add it into the aged hydroxyaluminum pillaring solution, stir it mechanically for 2 hours, and perform several times of centrifugation and washing after the reaction to obtain hydroxyaluminum modified montmorillonite powder;

[0045] 4) The hydroxyaluminum-modified montmorillonite was dried at 45°C, then crushed...

Embodiment 2

[0051] Preparation of dry method sodium dodecylsulfonate (SDS) modified montmorillonite:

[0052] 1) Put the montmorillonite in an oven at 45°C for 3 hours to remove the adsorbed water;

[0053] 2) Add 4 g of sodium dodecylsulfonate (SDS) to 24 g of montmorillonite, mix well, and place in a muffle furnace for calcination at 250° C. for 30 min. After the calcination is completed, cool to room temperature in air;

[0054] 3) Sodium dodecylsulfonate (SDS) modified montmorillonite was dried at 45°C, then pulverized and ground, and sodium dodecylsulfonate (SDS) within the particle size range of 45μm-90μm was collected with a sieve. ) modified montmorillonite powder.

[0055] Sampling preparation: take 1000g of Shanxi anthracite, particle size range 45μm-90μm; take 30g dry-process sodium dodecylsulfonate (SDS) modified montmorillonite powder, particle size range 45μm-90μm 。

[0056] The coal powder and the dry-process sodium dodecylsulfonate (SDS) modified montmorillonite powder...

Embodiment 3

[0061] The difference with embodiment 2 is:

[0062] Preparation of dry method sodium dodecylsulfonate (SDS) modified montmorillonite:

[0063] 1) Put the montmorillonite in an oven at 45°C for 3 hours to remove the adsorbed water;

[0064] 2) Add 4 g of sodium dodecylsulfonate (SDS) to 20 g of montmorillonite, mix well, and place in a muffle furnace for calcination at 250° C. for 35.5 min. After the calcination is completed, cool to room temperature in air;

[0065] 3) Dry the sodium dodecylsulfonate (SDS) modified montmorillonite at 45°C, then pulverize and grind, and collect sodium dodecylsulfonate ( SDS) modified montmorillonite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com