Method for recycling acetylene from slag slurry

A technology of slurry and acetylene, which is applied in the parts of acetylene gas generators, acetylene generators, petroleum industry, etc., can solve problems such as environmental pollution, safety hazards, and enterprise losses, so as to reduce production costs, increase safety, Significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

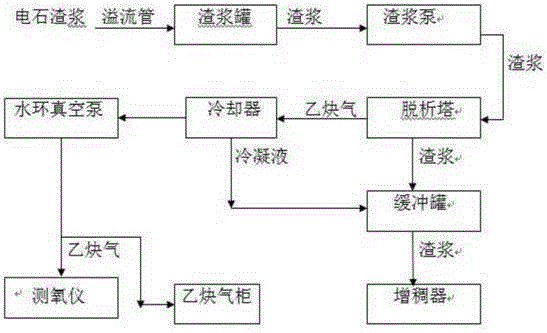

[0008] attached by figure 1 It can be seen that in the present invention, the calcium carbide slurry overflowed from the generator of the acetylene station is recycled from the overflow to the slurry tank through a closed pipeline, and then pumped to the desorption tower through the slurry pump, and the negative pressure of the desorption tower is provided by a water ring vacuum pump. The vacuum degree is controlled at -80Kpa ~ -55Kpa, and the temperature of the slurry is controlled at 50°C ~ 60°C. Under this condition, the acetylene gas contained in the water can basically be completely recovered. The ring vacuum pump sends it to the steam-water separator, and the separated acetylene gas first enters the oxygen analyzer to measure its oxygen content, which is linked to the switch of the on-site automatic valve to control the direction of the subsequent acetylene gas. 1.8%, the program automatically opens the automatic valve of the acetylene gas tank; if the oxygen content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com