A kind of preparation method of high elastic thermoplastic polyurethane foamed particles and molded body

A thermoplastic polyurethane and foamed particle technology, applied in the field of preparation of thermoplastic polyurethane foamed particles, can solve the problems of restricting large-scale preparation of foamed materials, high saturation pressure and temperature pressure relief rate, etc., and achieves easy industrial production, shrinkage rate and the like. Low, simple and easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

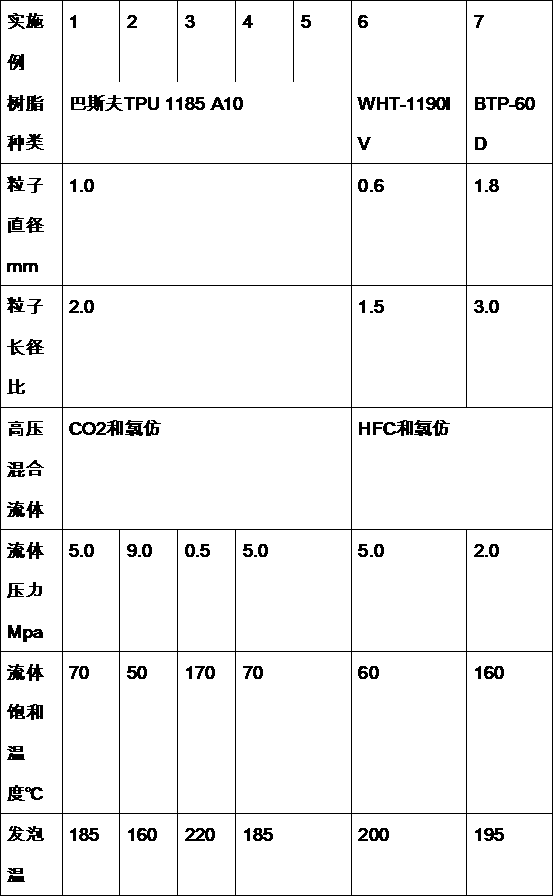

[0033] In the present embodiment, thermoplastic polyurethane selects German BASF Elastollan® polyurethane TPU 1185 A10, and the preparation method of this thermoplastic polyurethane expanded particle comprises the following steps:

[0034] (1) Inject thermoplastic polyurethane particles (BASF TPU 1185 A10, Germany) into a single screw, and melt-extrude to prepare thermoplastic polyurethane particles with a diameter of 1 mm and an aspect ratio of 2.0;

[0035] (2) Put the thermoplastic polyurethane particles into the autoclave, and feed the high-pressure mixed fluid formed by mixing CO2 and chloroform at a pressure of 5.0MPa, so that the high-pressure mixed fluid reaches saturation in the thermoplastic polyurethane particles, and the saturation temperature is 70°C. obtain saturated thermoplastic polyurethane particles;

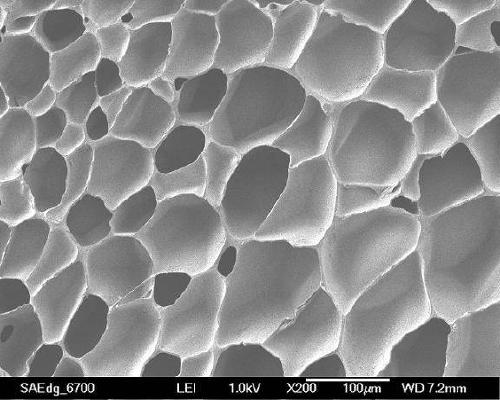

[0036] (3) Put the saturated thermoplastic polyurethane particles into a continuous hot air channel at a temperature of 185° C. to foam for 120 seconds to obta...

Embodiment 2

[0041] In the present embodiment, thermoplastic polyurethane selects German BASF Elastollan® polyurethane TPU 1185 A10, and the preparation method of this thermoplastic polyurethane expanded particle is basically the same as the preparation method in embodiment 1, and difference is:

[0042] In step (2), the pressure of the high-pressure mixed fluid is 9.0MPa, and the saturation temperature is 50°C;

[0043] In step (3), the saturated thermoplastic polyurethane particles are placed in a continuous hot air channel at a temperature of 160° C. for foaming for 180 seconds to obtain thermoplastic polyurethane micro-foamed particles.

[0044] The thermoplastic polyurethane micro-expanded particles have a 100% closed-cell structure, and the cell size is 130-170 μm. The density of the thermoplastic polyurethane microcellular particles is 0.163 / cm3.

[0045] The above foamed thermoplastic polyurethane particles were molded and manufactured, the specific process was the same as that in...

Embodiment 3

[0048] In the present embodiment, thermoplastic polyurethane selects German BASF Elastollan® polyurethane TPU 1185 A10, and the preparation method of this thermoplastic polyurethane expanded particle is basically the same as the preparation method in embodiment 1, and difference is:

[0049] In step (2), the pressure of the high-pressure mixed fluid is 0.5MPa, and the saturation temperature is 170°C;

[0050] In step (3), the saturated thermoplastic polyurethane particles are placed in a continuous hot air channel at a temperature of 220° C. for foaming for 40 seconds to obtain thermoplastic polyurethane micro-foamed particles.

[0051] The thermoplastic polyurethane micro-foamed particles have a 100% closed-cell structure, and the cell size is 120-170 μm. The thermoplastic polyurethane microcellular particles had a density of 0.183 g / cm3.

[0052] The above foamed thermoplastic polyurethane particles were molded and manufactured, the specific process was the same as that in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com