A method for reducing impurities of uranium, thorium, titanium, iron and aluminum in zircon sand

A zircon sand and impurity technology, applied in the direction of non-metallic elements, etc., can solve the problems that titanium cannot be leached and the leaching effect is not good, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

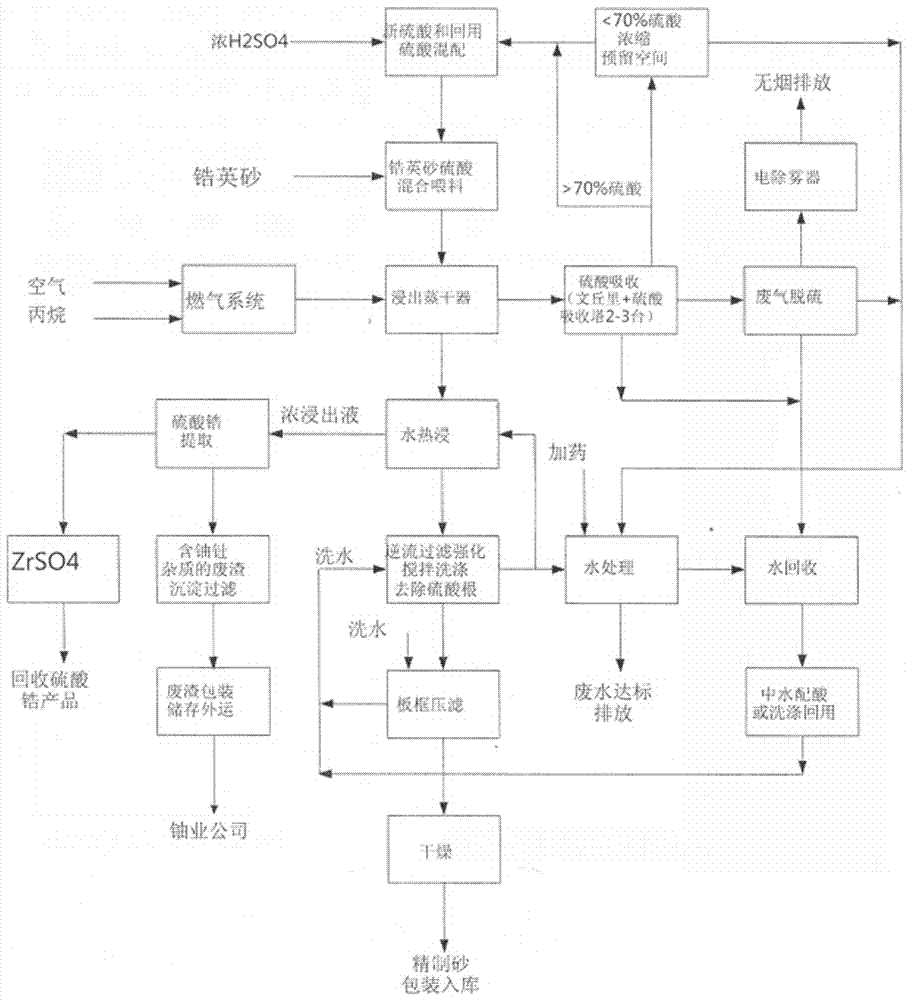

Image

Examples

Embodiment 1

[0025] A method for reducing impurities of uranium, thorium, titanium, iron and aluminum in zircon sand, comprising the steps of:

[0026] The particle size is 80-140 mesh accounting for 0.44%, 140-160 mesh accounting for 0.69%, 160-200 mesh accounting for 2.57%, ≤200 mesh accounting for 96.2% zircon sand and 70% sulfuric acid according to the mass ratio of 1:0.6 After mixing, send it to the leaching and evaporator for leaching and evaporation. The leaching temperature is 300 degrees Celsius, the leaching time is 2 hours, the evaporation temperature is less than 500 degrees Celsius, and the evaporation time is 30 minutes. Free sulfuric acid in the solid zircon sand after evaporation Less than 0.5%, the solid zircon sand is stirred and immersed in water at 100 degrees Celsius, and the solid zircon sand after water immersion is washed with water 5 times the mass of the zircon sand until neutral, and dried at 105 degrees Celsius to obtain the product.

Embodiment 2

[0028] A method for reducing uranium, thorium, titanium, iron and aluminum impurities in zircon sand, which is to mix zircon sand with ≤200 mesh accounting for 96.2% and 70% sulfuric acid at a mass ratio of 1:0.6, and then send it to a leaching and evaporating device The leaching temperature is 280 degrees Celsius, the leaching time is 1.8 hours, the evaporation temperature is less than 500 degrees Celsius, and the evaporation time is 30 minutes. The free sulfuric acid in the solid zircon sand after evaporation is less than 0.5%, and the solid zircon sand is in Stirring and water immersion are carried out at 80 degrees centigrade, the solid zircon sand after water immersion is washed with water three times the mass of the zircon sand until neutral, and dried at 105 degrees centigrade.

Embodiment 3

[0030] A method for reducing uranium, thorium, titanium, iron and aluminum impurities in zircon sand, which is to mix zircon sand with ≤200 mesh accounting for 96.2% and 70% sulfuric acid at a mass ratio of 1:0.6, and then send it to a leaching and evaporating device leaching to dryness, leaching temperature is 260°C, leaching time is 1.5 hours, evaporation temperature is less than 500°C, evaporation time is 30 minutes, free sulfuric acid in solid zircon sand after evaporation is less than 0.5%, and solid zircon sand is in Stirring and water immersion at 85°C, washing the solid zircon sand with water 4.5 times the mass of the zircon sand until neutral, and drying at 105°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com